Tungsten production waste water convection purification device

A purification device and a technology for producing wastewater, which is applied in metallurgical wastewater treatment, water pollutants, water/sewage treatment, etc. It can solve problems such as incomplete purification work, mutual purification that cannot achieve the expected effect, and a sudden drop in the falling speed of wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

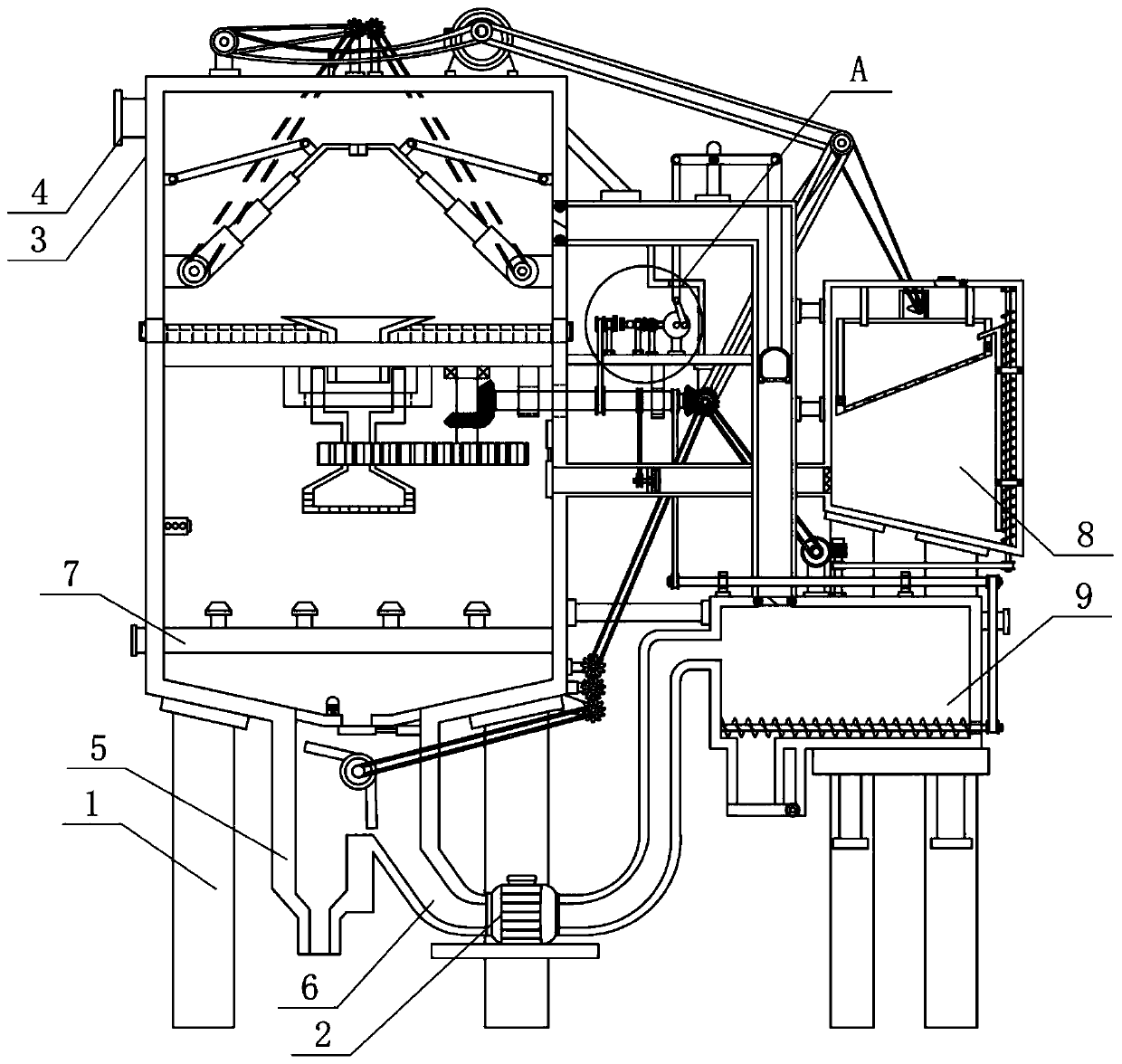

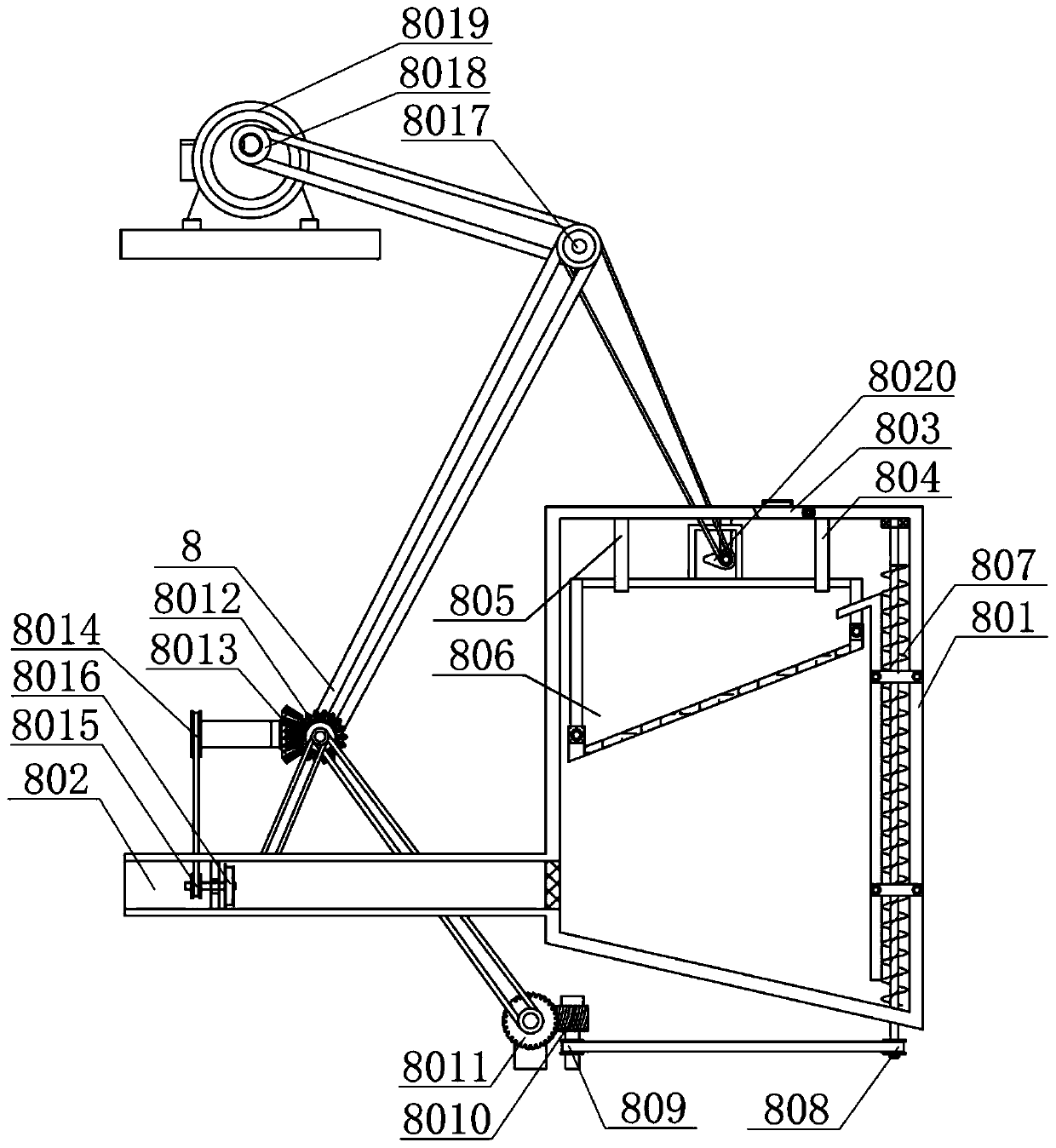

[0025] A convection purification device for tungsten production wastewater, such as Figure 1-5 As shown, it includes an underframe 1, a water pump 2, a high-efficiency atomization neutralization device 3, a waste water inlet 4, a purified water outlet 5, a circulation inlet 6, an exhaust gas injection port 7, a nitrogen dioxide purification device 8 and a well type purification device 9; A water pump 2 is installed at the bottom of the front end of the chassis 1; an efficient atomization neutralization device 3 is installed on the left side of the top of the chassis 1; the left end of the water pump 2 is connected to the circulation inlet 6, and the top of the circulation inlet 6 is connected to the high efficiency atomization neutralization device 3 The right end of the water pump 2 is connected to the well type purification device 9 through a pipeline, and the left top of the well type purification device 9 is connected to the high-efficiency atomization neutralization devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com