Method and equipment for preparing electrolyzed agricultural water and fertilizers

A technology for water, fertilizer and agriculture, applied in agriculture, electrolysis process, electrolysis components, etc., can solve the problem that pH and orp cannot be adjusted independently, and achieve the effect of fast time control and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

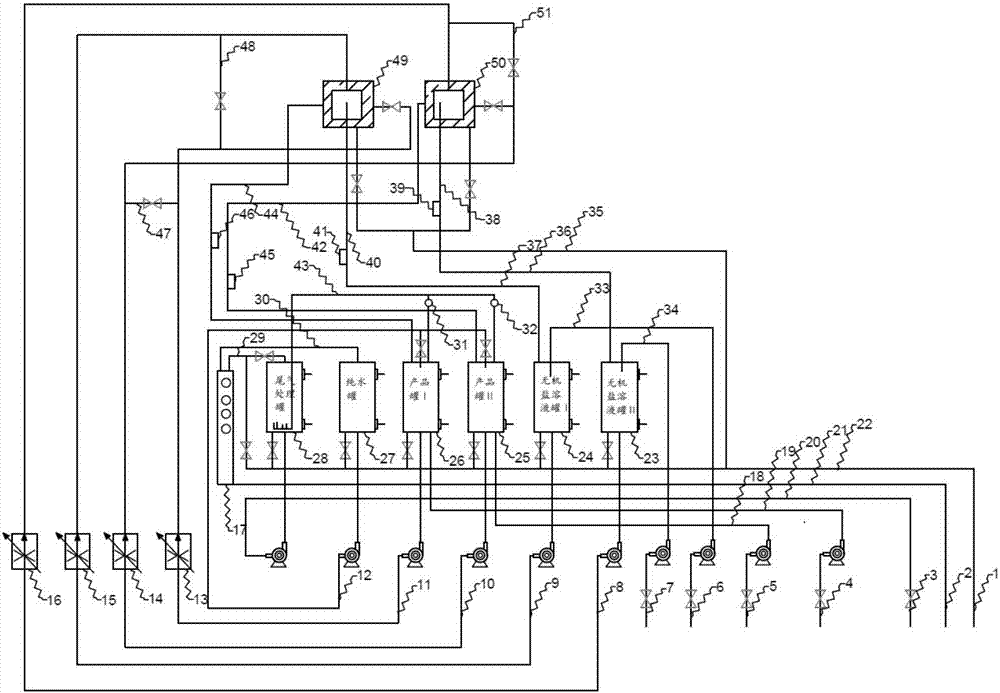

[0050] [1] Add the pure water after tap water purification equipment (17) evolution in product tank I (26) and product tank II (25), in inorganic salt solution tank I (24) and inorganic salt solution tank II (23) Add the inorganic salt solution, the inorganic salt is a saturated NaCl solution;

[0051] [2] Pass the liquid in the product tank I (26) into the first chamber I of the flow-type electrolytic cell I (49), and pass the solution in the inorganic salt solution tank I (24) into the flow-type electrolytic cell I In the second chamber I of (49), electrolysis is carried out, wherein the first chamber I is set as the anode, and the second chamber I is set as the cathode, and the voltage is 7V; with the flow control device I (13) and the flow control device III ( 15) Control the flow ratio to 1:1; turn on the air pump I (31) for tail gas treatment.

[0052] [3] carry out the pH test to the first electrolytic solution I flowing out from the first chamber I of flow-type electr...

Embodiment 2

[0059] [1] Add the pure water after tap water purification equipment (17) evolution in product tank I (26) and product tank II (25), in inorganic salt solution tank I (24) and inorganic salt solution tank II (23) Add the inorganic salt solution, the inorganic salt is saturated K 2 CO 3 solution;

[0060] [2] Pass the liquid in the product tank I (26) into the first chamber I of the flow-type electrolytic cell I (49), and pass the solution in the inorganic salt solution tank I (24) into the flow-type electrolytic cell I In the second chamber I of (49), electrolysis is carried out, wherein the first chamber I is set as the cathode, and the second chamber I is set as the anode, and the voltage is 6V; with the flow control device I (13) and the flow control device III ( 15) Control the flow ratio to 1:1; turn on the air pump I (31) for tail gas treatment.

[0061] [3] carry out the pH test to the first electrolytic solution I flowing out from the first chamber I of flow-type el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com