a cement mixer

A technology of cement mixer and mixing space, applied in the field of cement mixing, can solve the problems of affecting use, time-consuming and laborious, low efficiency, etc., and achieve the effect of being convenient for next use and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

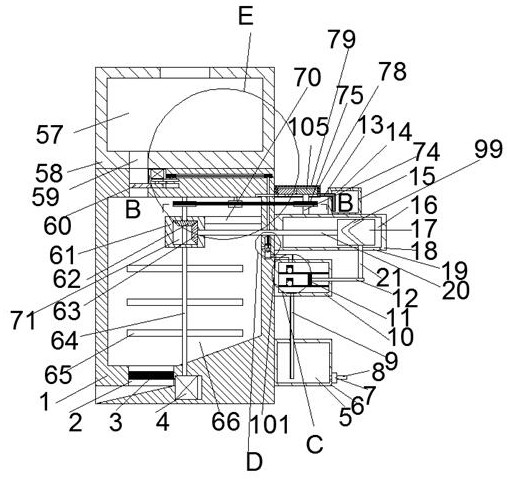

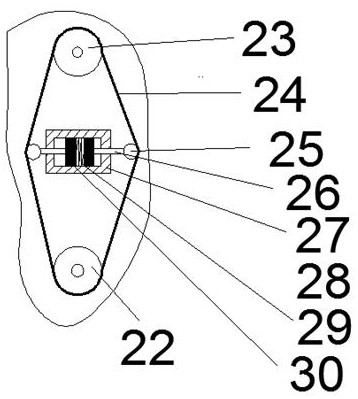

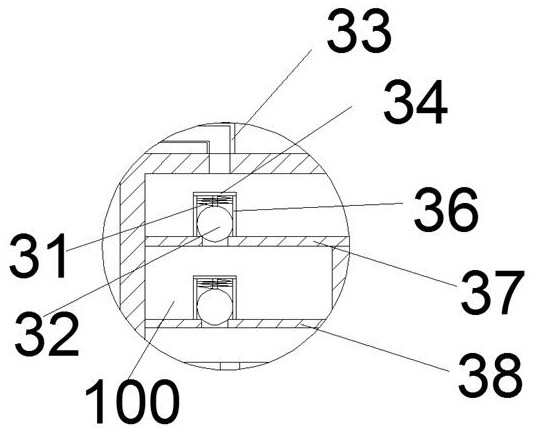

[0019] Embodiment of the present invention: when in use, start the second motor 84, the second motor 84 drives the second power shaft 85 to rotate, the second power shaft 85 drives the first gear 88 to rotate, and the first gear 88 drives the first rack 60 to move , at the same time, the first bevel gear 62 drives the third bevel gear 63 for meshing transmission, the third bevel gear 63 drives the first transmission shaft 20 to rotate, the first transmission shaft 20 drives the scroll wheel 17 to rotate, and through the screw thread 99 on the scroll wheel 17, Push the piston 11 to move left and right, so that the pressure difference generated by the up and down movement of the marble 32 transports the water from the water tank 6 to the mixing space 66. After the cement is mixed, it is taken out through the electric control door 3, and then the electromagnet is energized, and the first pulley 40 drives the second The pulley 75 rotates, the second pulley 75 drives the second tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com