Loop type wire drawing machine

A wire drawing machine and looper technology, applied in wire drawing dies and other directions, can solve the problems of poor equipment operation stability and safety, unstable steel wire quality, slow drawing speed, etc., to improve drawing quality, ensure production efficiency and The effect of drawing quality, reducing the degree of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

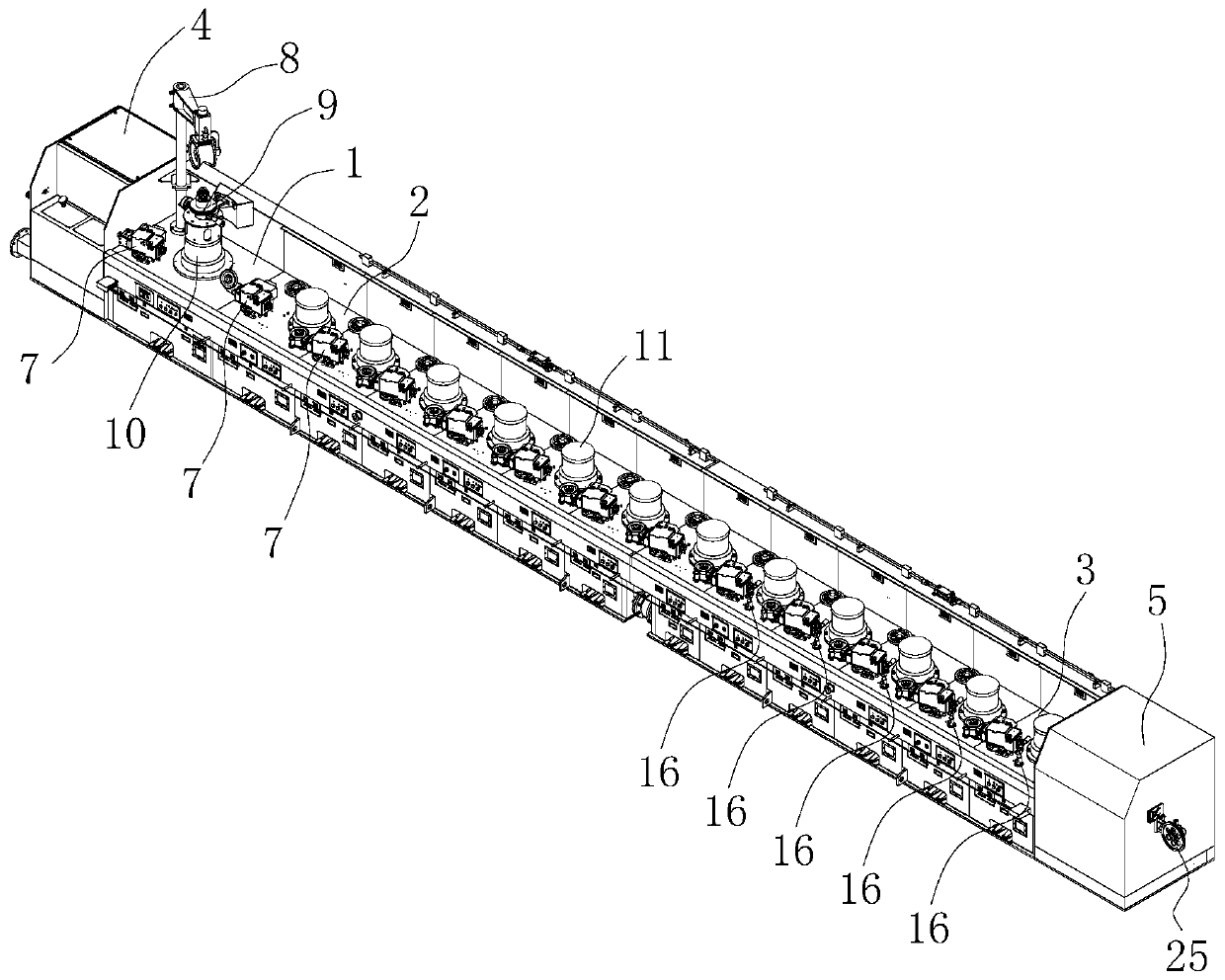

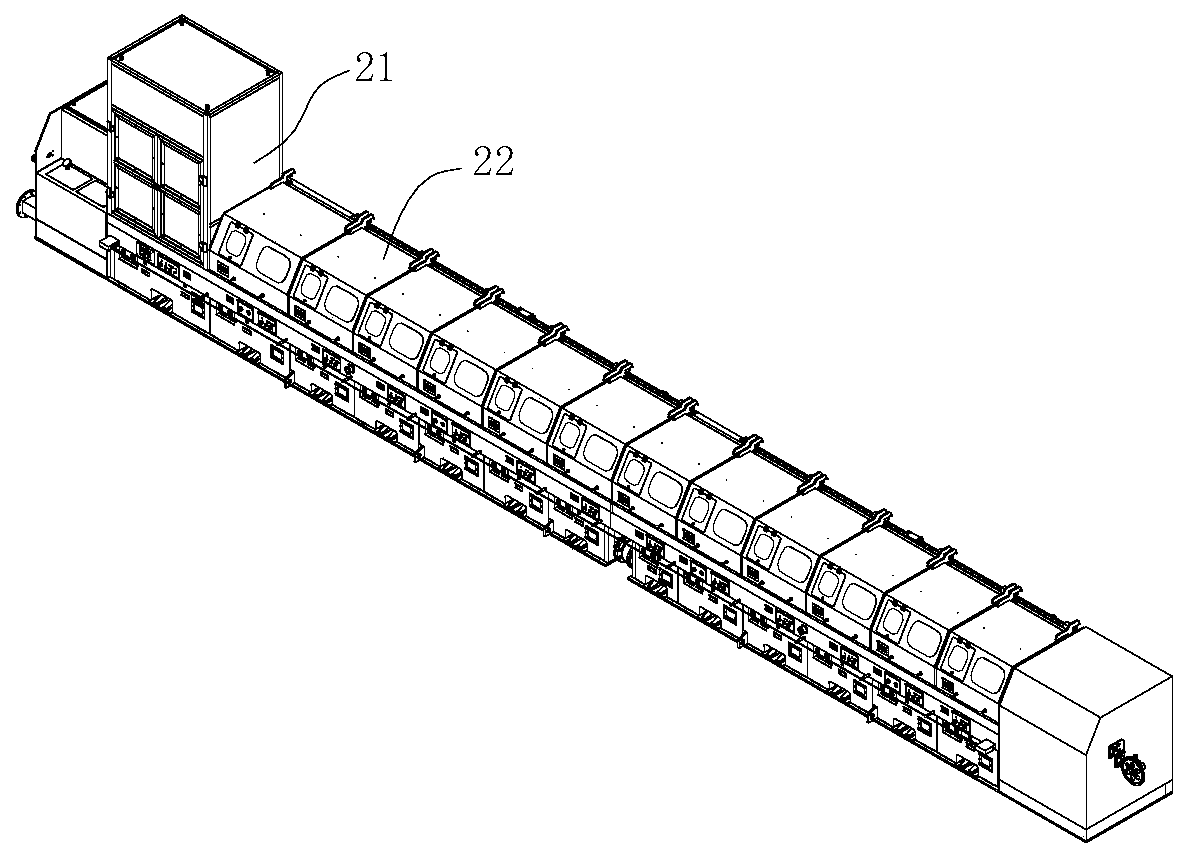

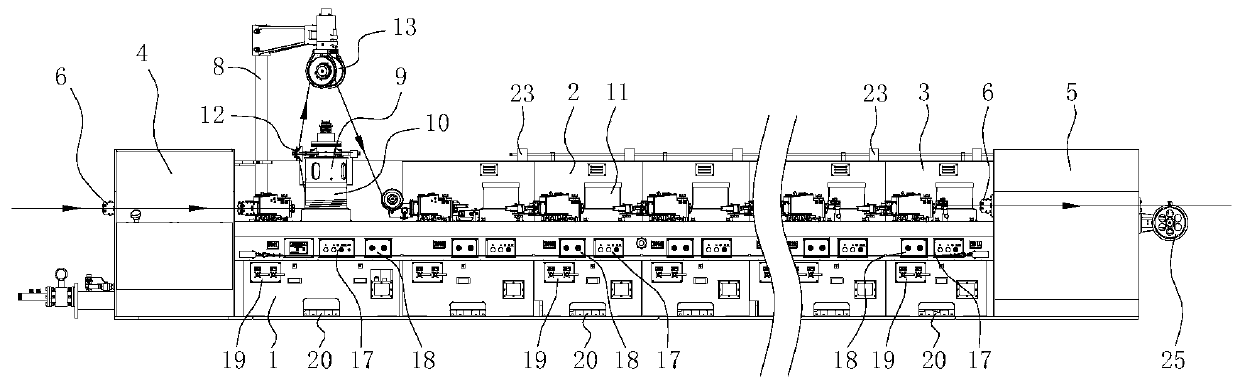

[0042] Such as Figure 1 to Figure 4 As shown, a looper-type wire drawing machine includes a first machine 1, several second machines 2 and a third machine 3 arranged in sequence from the equipment inlet end to the outlet end, and also includes a water tank 4 and an electric control cabinet 5. The water tank 4 is set at one end of the equipment to provide circulating water for equipment cooling. The electric control cabinet 5 is set at the other end of the equipment to provide power control. The cross-shaped roller 6 guides the incoming wire to enter the equipment, and the cross-shaped roller 6 at the outlet end of the equipment guides the incoming wire to exit the equipment.

[0043] The first machine platform 1 is provided with a mold box 7, a hanger device 8, a wire pulling device 9 and a first reel 10. The line connecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com