An air separation device for spray dryer

A spray dryer and air separation technology, which is applied in the direction of combination device, separation method, dispersed particle separation, etc., to achieve the effect of reducing requirements, reducing the influence of oxidation, and improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

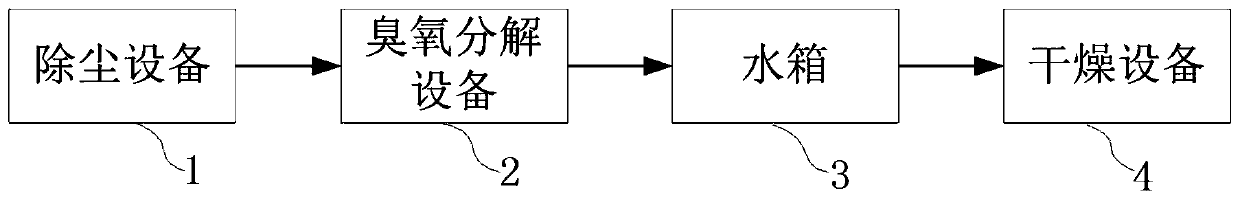

[0032] see figure 1 Shown, the present invention is a kind of air separation device that is used for spray dryer, comprises dedusting equipment 1, ozonolysis equipment 2, water tank 3 and drying equipment 4, and air successively from dedusting equipment 1, ozonolysis equipment 2, water tank 3 and The drying equipment 4 enters the spray dryer.

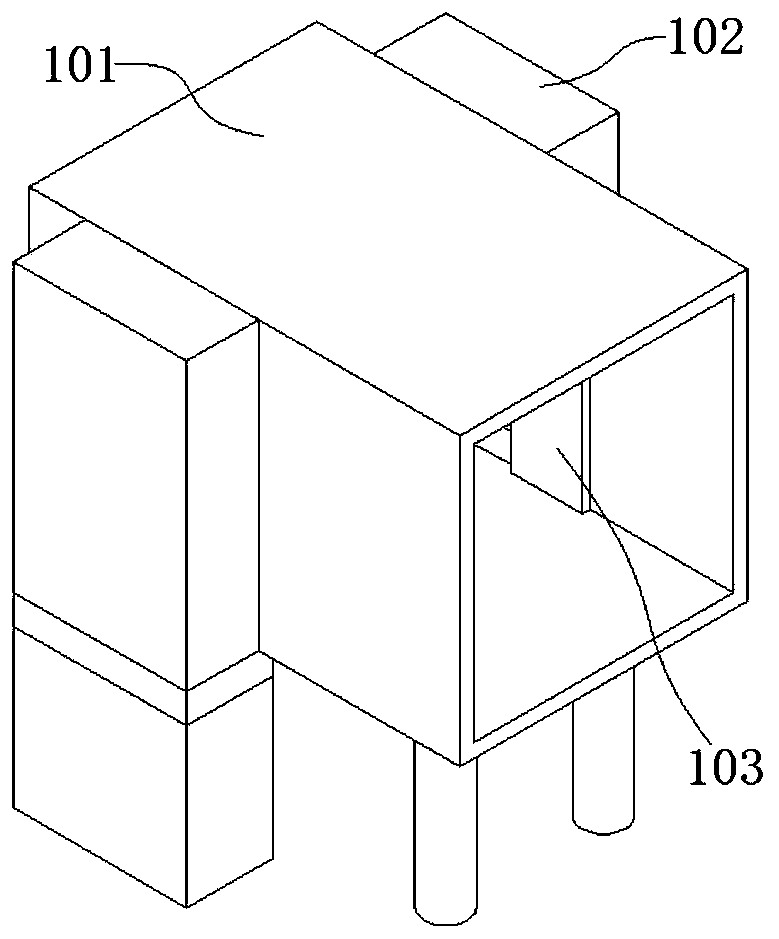

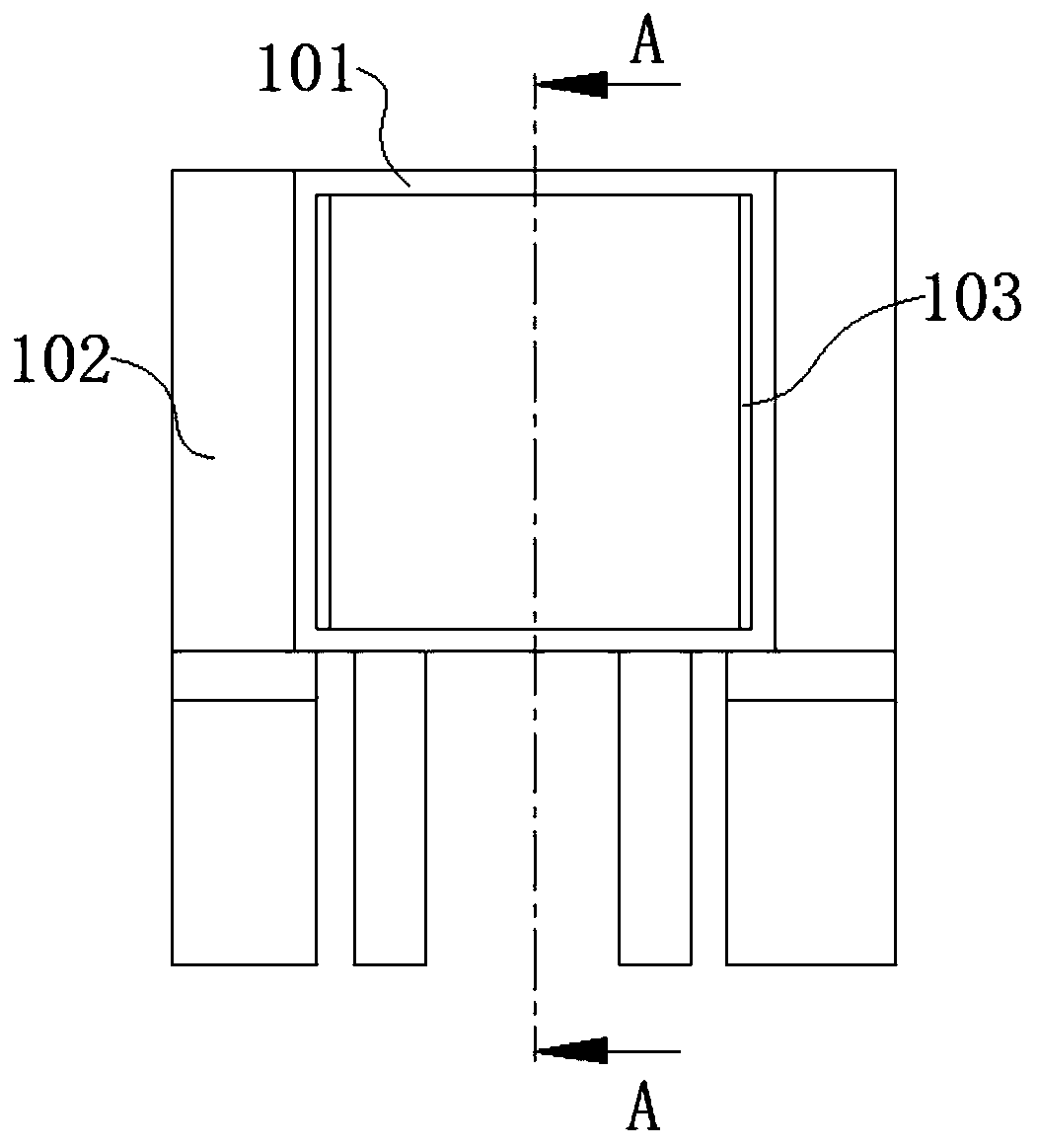

[0033] like Figure 2-4 As shown, the dust removal equipment 1 includes a ventilation box 101 and a dust collection box 106. One surface of the ventilation box 101 is connected to the dust collection box 106. Side boxes 102 are respectively arranged on both sides of the ventilation box 101. Two opposite inner surfaces of the ventilation box 101 are provided with ionizers. Plate 103, one surface of side box 102 is provided with adsorption plate 104, one surface of adsorption plate 104 is provided with peeling knife 105, one surface of ventilation box 101 is provided with dust outlet, the position of dust outlet is adapted to the positio...

Embodiment 2

[0042] see Figure 1-10 As shown, the present invention is an air separation device for a spray dryer. Its working principle is: after the air enters the device, it first passes through the dust removal device 1, and applies a DC high voltage on the ionization plate 103 of the dust removal device 1, and passes through the strong The electric field ionizes the dust in the air, and then the ionized dust is adsorbed to the surface of the board through the adsorption plate 104, and then the dust on the surface of the adsorption plate 104 is scraped into the dust collection box 106 by the stripping knife 105, and the oxygen in the air passes through After the dust removal equipment 1, ozone will be generated under the action of a strong electric field. In order to prevent the strong oxidative properties of ozone from affecting the substances in the spray dryer, the ozone is decomposed by the ozonolysis equipment 2, and the ozone is decomposed by ultraviolet or infrared rays. Improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com