A high-efficiency CNC tool maintenance turning center

A technology for machining centers and maintenance vehicles, which is applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc. It can solve the problems of wet lathes and prone to oxidation on the surface, and achieve the effect of reducing the impact of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

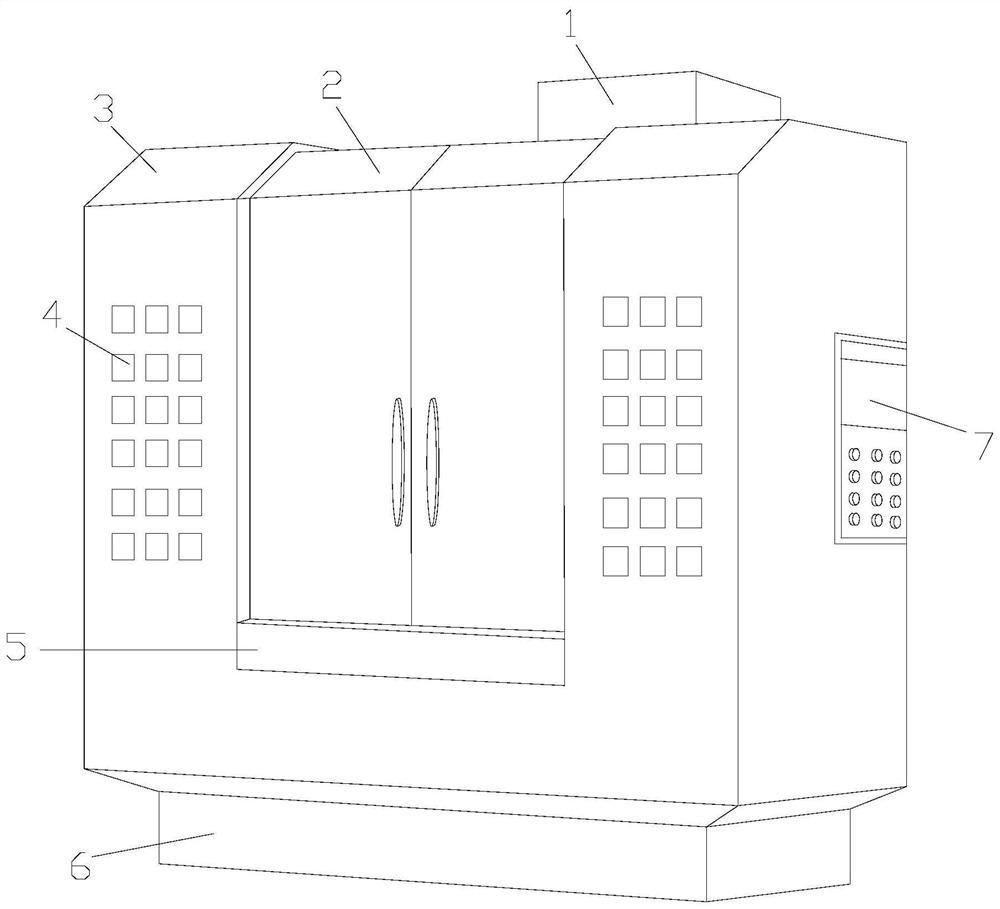

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The present invention provides a high-efficiency CNC tool maintenance turning machining center, the structure of which includes a power box 1, a protective door 2, a CNC turning machine tool 3, an observation piece 4, a slider seat 5, a base 6, a control panel 7, and a tool maintenance device 8, The power box 1 is welded and fixed above the CNC turning machine tool 3, the observation sheet 4 is installed on the left and right sides of the positive end surface of the CNC turning machine tool 3 by inlaying, the slide bar seat 5 is welded to the base 6, and the protection The door 2 is installed inside the sliding bar seat 5 in an embedded manner, a tool maintenance device 8 is provided inside the CNC turning machine tool 3 , and the control panel 7 is arranged on the right side of the CNC turning machine tool 3 .

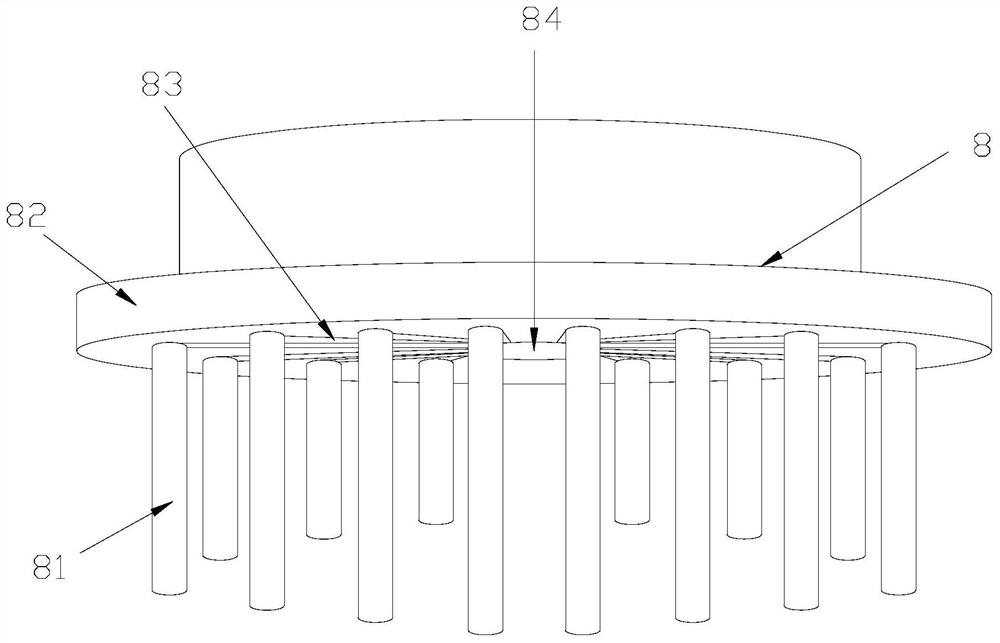

[0031] The tool maintenance device 8 includes a maintenance cover 81, a cutter head 82, a tool slid...

Embodiment 2

[0039] as attached Figure 7 Shown:

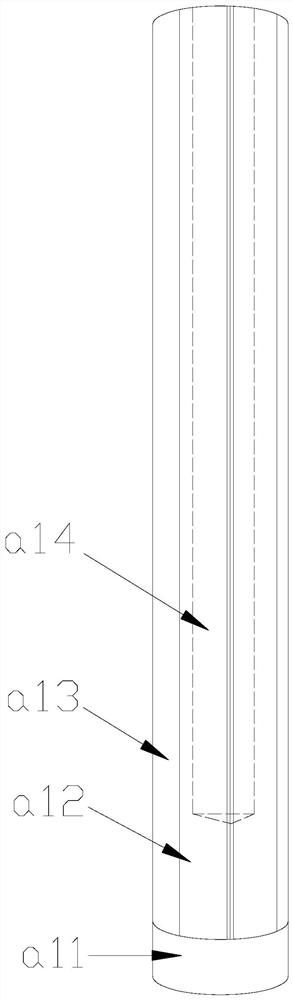

[0040] The present invention provides a high-efficiency CNC tool maintenance turning machining center. The active pressure mechanism a12 includes a left stop q1, a magnetic strip q2, a right stop q3, a curved elastic strip q4, and a traction strip q5. The magnetic strip q2 A total of two are provided and are fixedly connected with the left blocking piece q1 and the right blocking piece q3 respectively, the curved elastic strip q4 is connected with the traction strip q5, and the curved elastic strip q4 is installed on the left blocking piece by embedding Inside q1, the left baffle q1 and right baffle q3 can be turned back and reset under the action of traction and rebound no matter whether they are unfolded from the inside to the outside or flipped from the inside to the inside through the curved elastic bar q4.

[0041] Wherein, the locking opening aa3 is provided with two recessed grooves, and the inside is an I-shaped groove, which is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com