Voltage-sharing constant voltage carbon brush supporting device

A support device and pressure-equalizing technology, applied in the direction of rotating current collectors, current collectors, electrical components, etc., can solve the problems of large carbon brush current, different contact pressure, affecting the safe and stable operation of generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

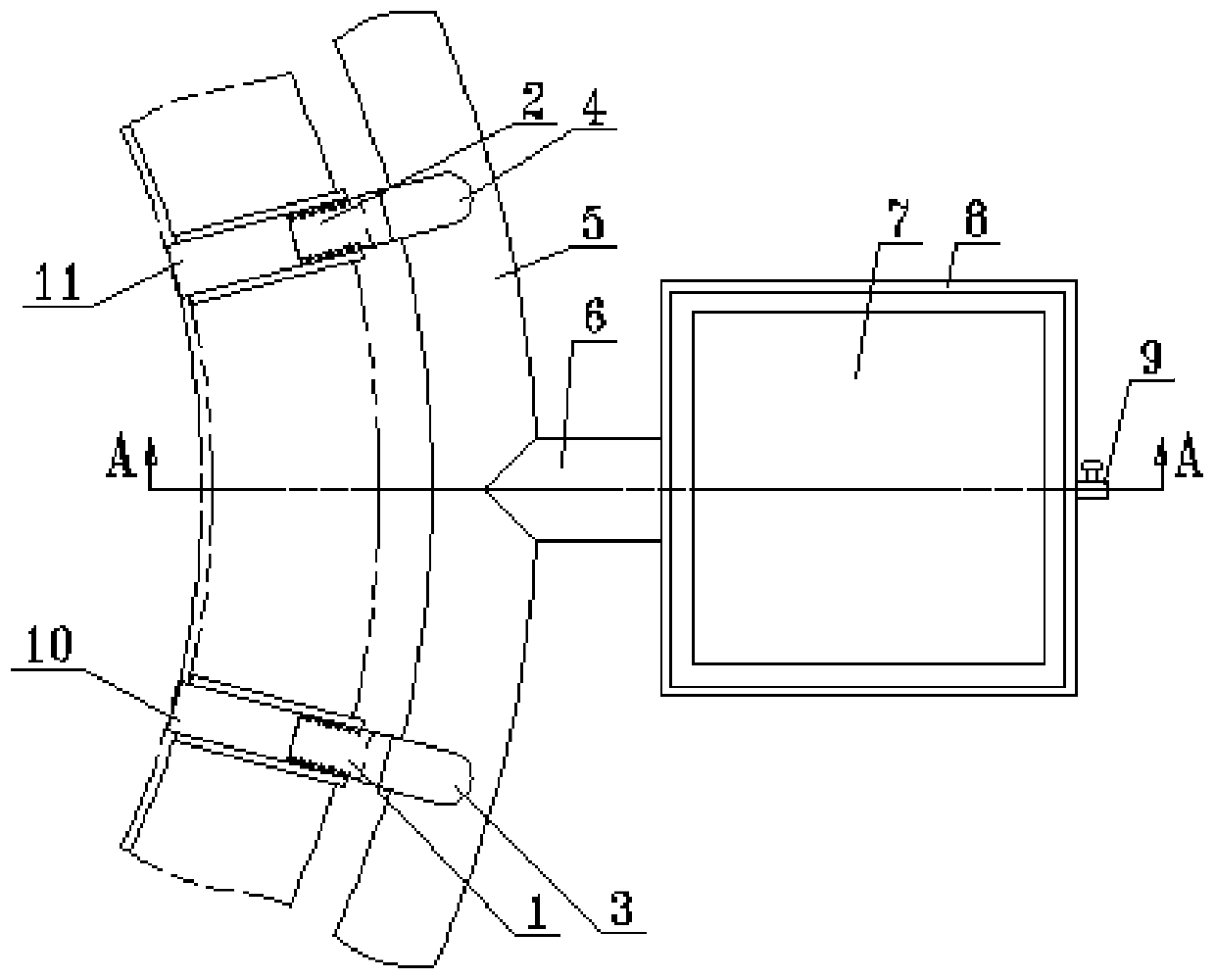

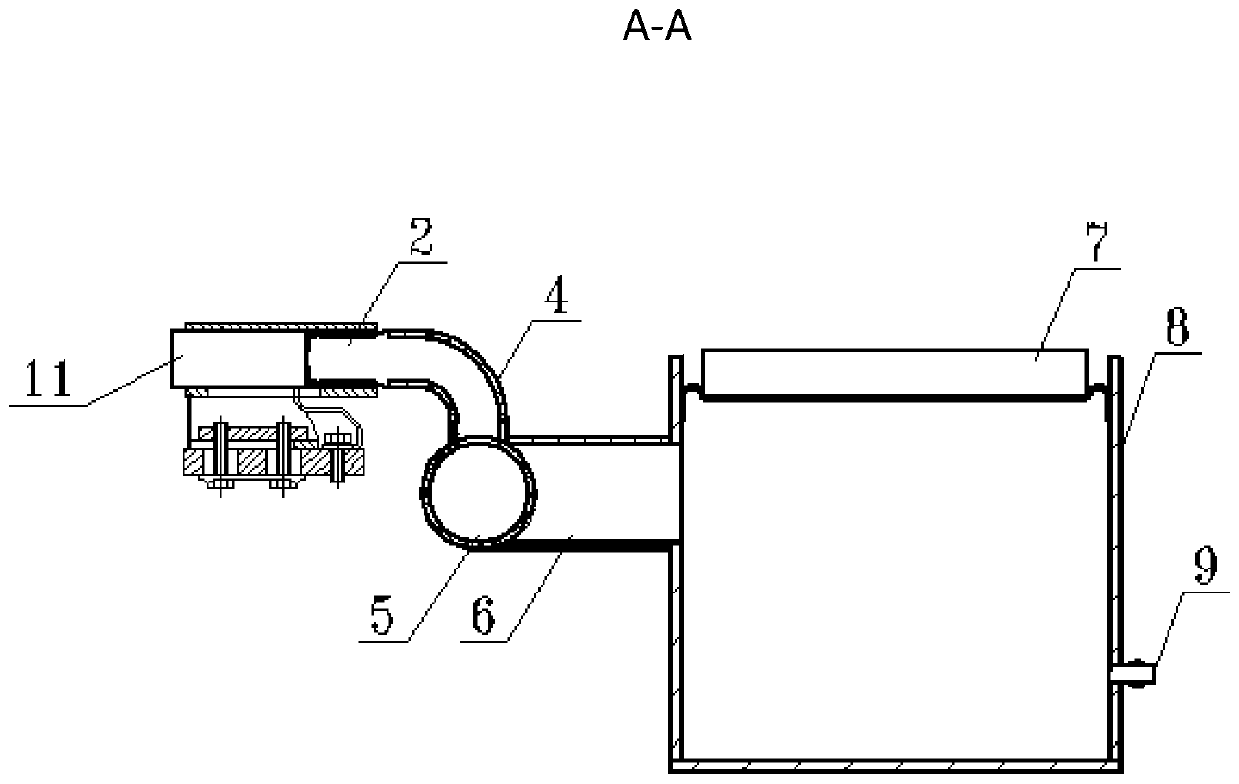

[0009] Such as figure 1 figure 2 As shown, a pressure-equalizing constant-pressure carbon brush support device consists of a first bellows 1, a second bellows 2, a first connecting branch 3, a second connecting branch 4, a ring pipe 5, a main pipe 6, and a counterweight 7. A sealed cylinder body 8 and a valve 9 are formed. The ring pipe 5 communicates with the sealing cylinder 8 through the main pipe 6. One end of the branch pipe 3 and the branch pipe 4 is drawn from the ring pipe 5, and the other end is respectively connected to the first bellows 1 and the second bellows 2, the first bellows 1 and the second bellows One end of the tube 2 in contact with the first carbon brush 10 and the second carbon brush 11 is sealed. The expansion and contraction lengths of the first corrugated tube 1 and the second corrugated tube 2 meet the use requirements of the wear amount of the carbon brush. The first bellows 1 and the second bellows 2 are made of class H insulating material. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com