A pressure monitoring clamping device for ultrasonic nonlinear testing

A technology of pressure monitoring and clamping devices, which is applied in measuring devices, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve wafer misalignment, detachment from samples, and reduced adhesion and other issues to achieve accurate and reliable experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

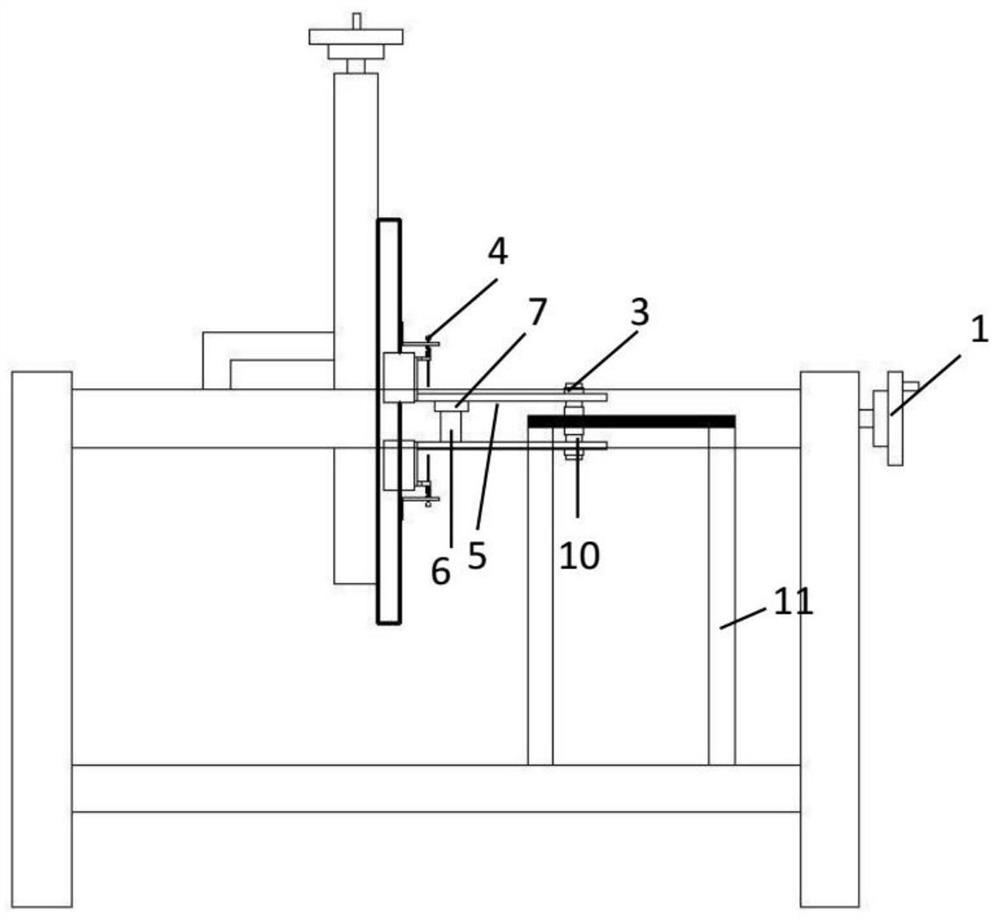

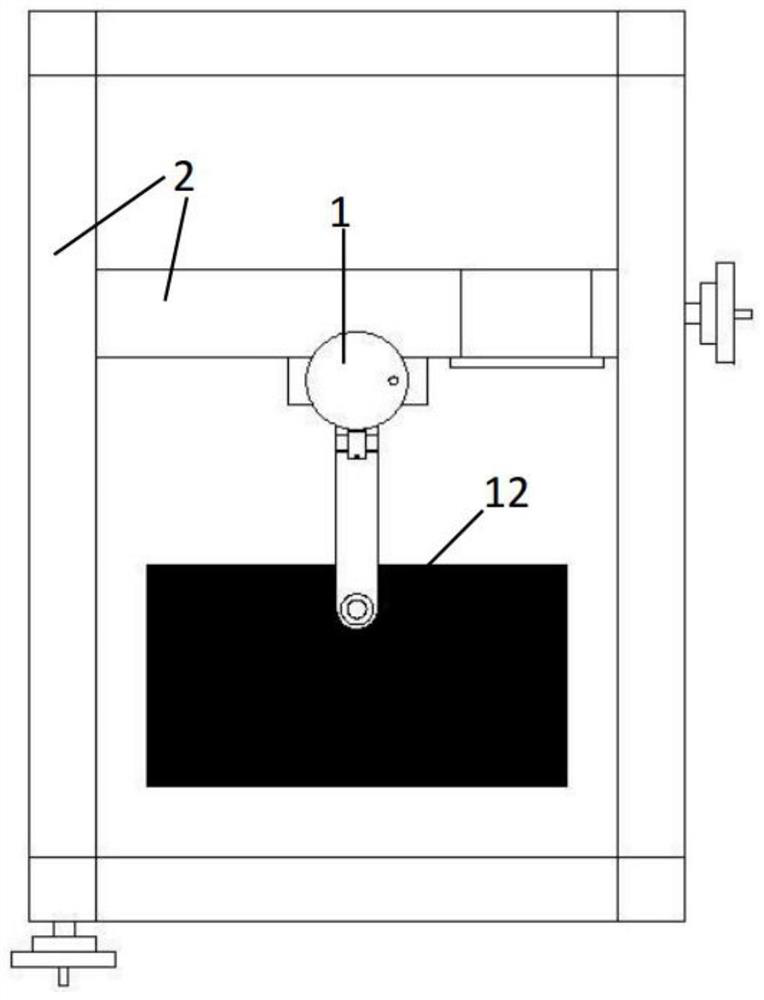

[0017] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a pressure monitoring clamping device for ultrasonic nonlinear testing, including a hand wheel (1), a linear guide rail (2), a probe nut (3), an eyebolt (4), a clamp arm (5), a pressure detection , chip (9), chip card slot (10), shelf (11), solder placement groove (13), lead hole (14), device frame (16), two long supports on the upper side of the device frame (16) A Y-direction bracket is added on the left side, the upper surface of the Y-direction bracket is flush with the upper surface of the device frame (16), a Z-direction bracket is welded in the middle of the outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com