Snap fastener ready-package bag unscrambler workbench

A workbench, quick-loading technology, applied in the directions of paper product packaging, transportation and packaging, and packaging item types, etc., can solve problems such as adverse effects on production rhythm and efficiency, rising production and storage costs, and heavy workload for on-site operators. , to achieve the effect of improving production efficiency and product quality, reasonable structure, reliable and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

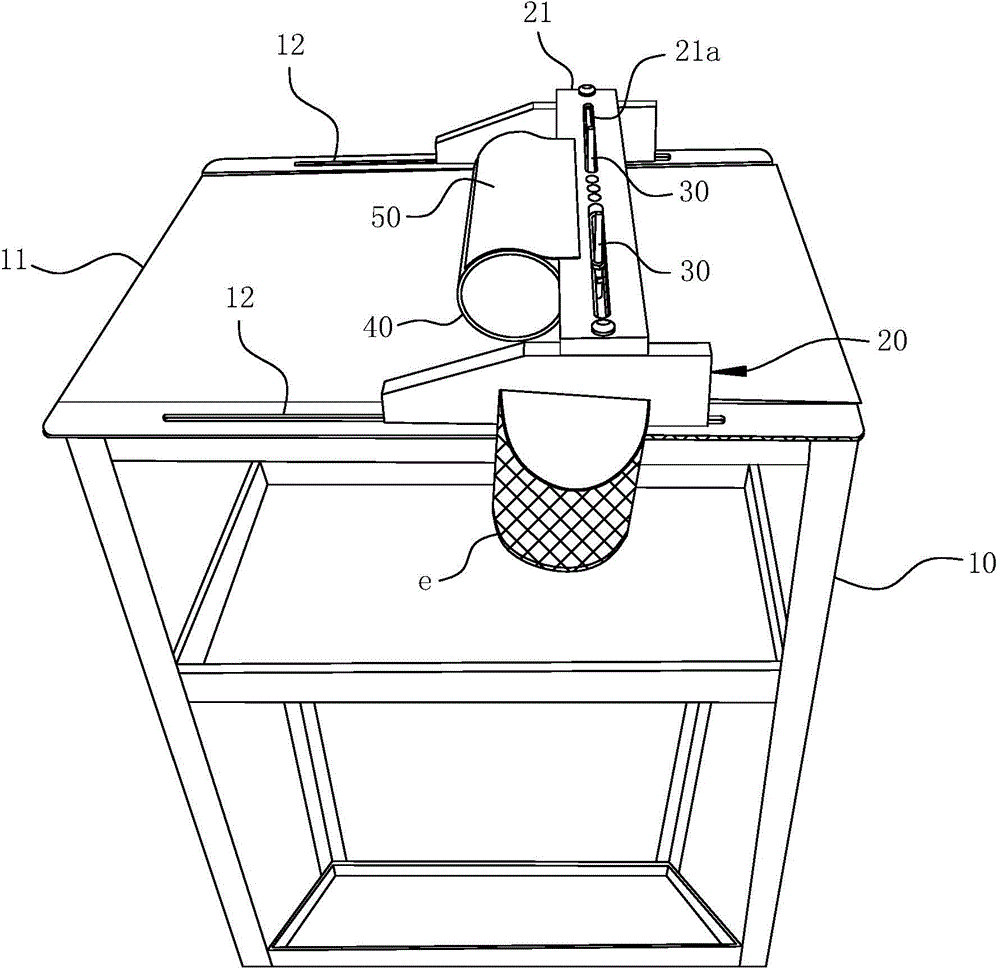

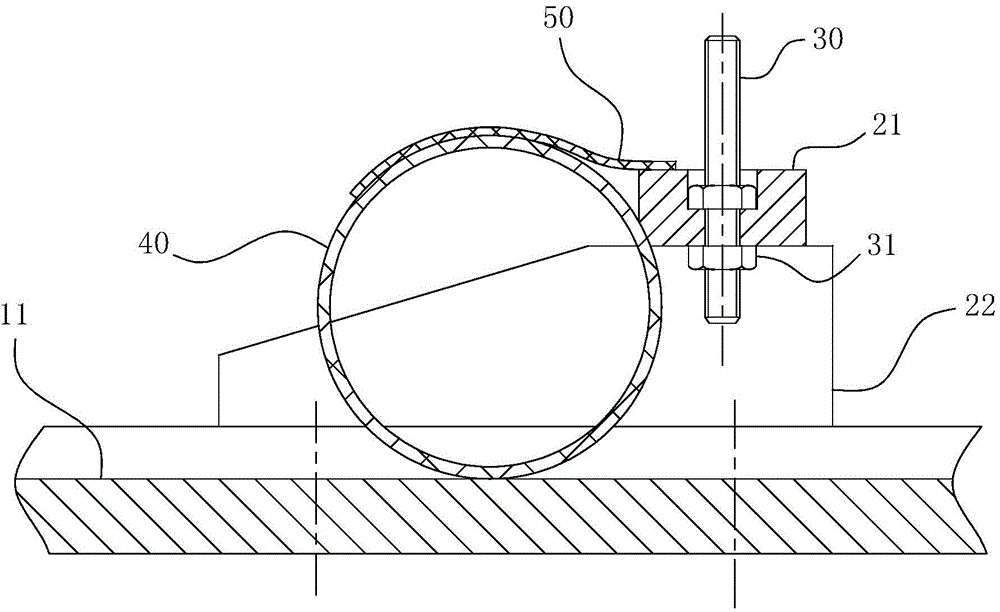

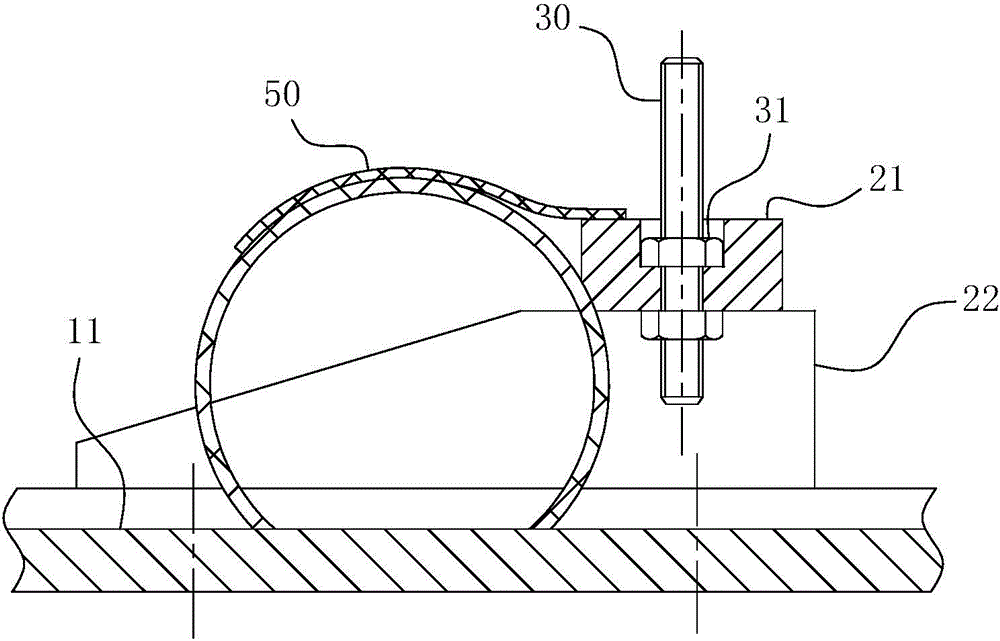

[0028] For ease of understanding, the specific structure and working method of the present invention are described as follows in conjunction with the accompanying drawings:

[0029] The specific structure of the present invention is as Figure 1-3 As shown, it includes a main base 10 with a frame-like shape. The main base body 10 is equipped with three layers of rectangular plate-shaped panels parallel to each other, wherein the middle and lower panels form a placement layer for placing auxiliary materials and other objects, and the uppermost panel constitutes the working surface 11 of the present invention for placing corresponding components. . The working platform 11 has leg portions 22 extending upwards on both sides of its long side, and a beam 21 is arranged on the supporting leg 22 to form a simply supported beam-like structure of the beam 21 relative to the working platform 11 . Each leg portion 22 is in a groove-like adjustable fit relationship with the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com