A quick-change needle bed for a power battery

A technology of power battery and needle bed, which is applied in the field of quick-change needle beds of power batteries, can solve the problems of inconsistent contact pressure between the positive and negative electrodes of lithium batteries, limit the fast charging capacity of lithium batteries, and reduce the performance of lithium batteries, etc., to achieve fast charging Stable capacity, guaranteed performance, and stable cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

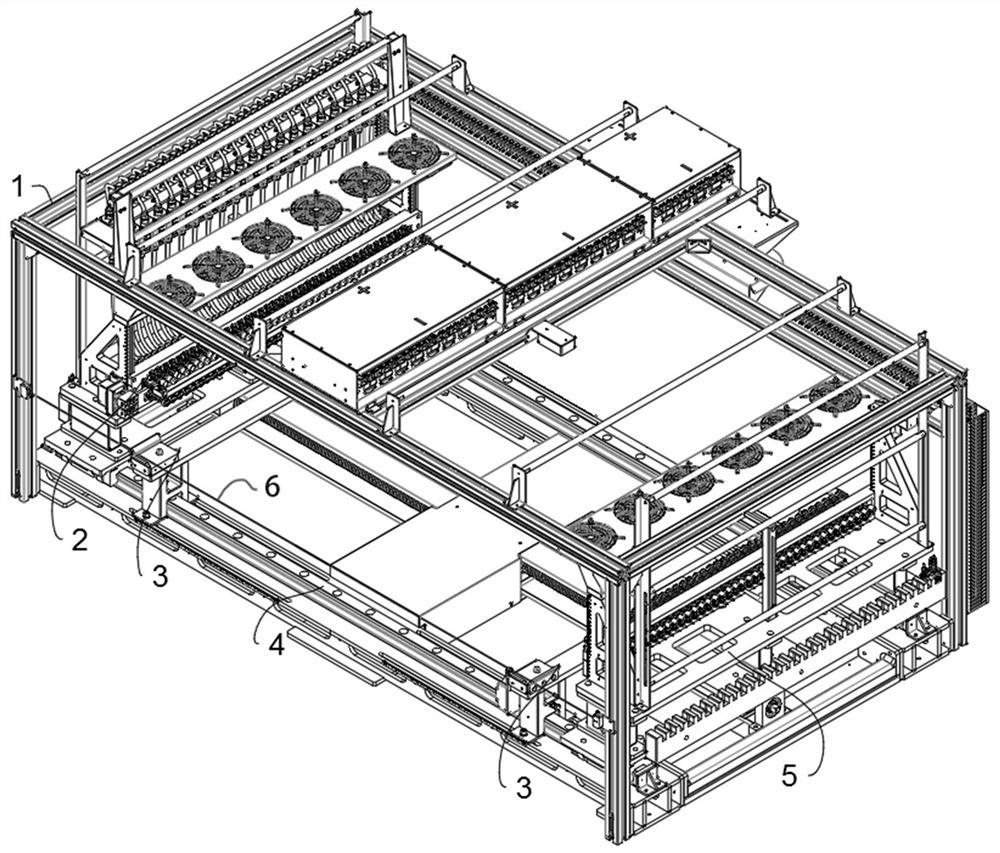

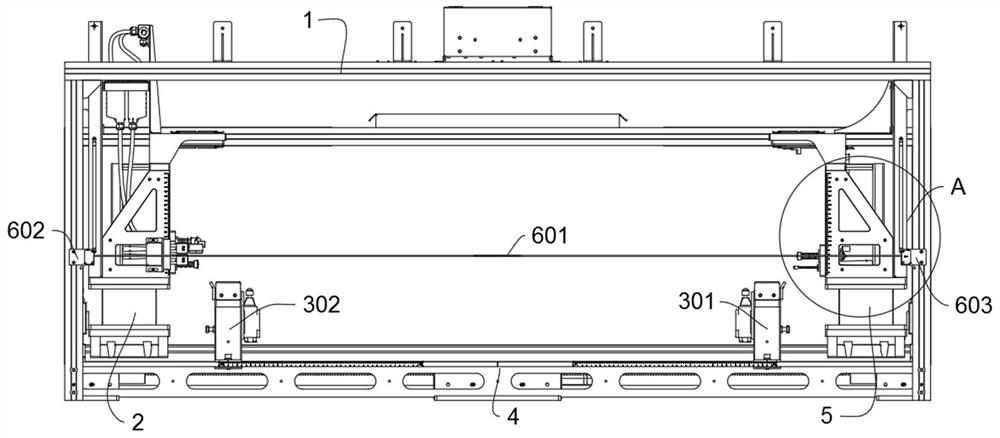

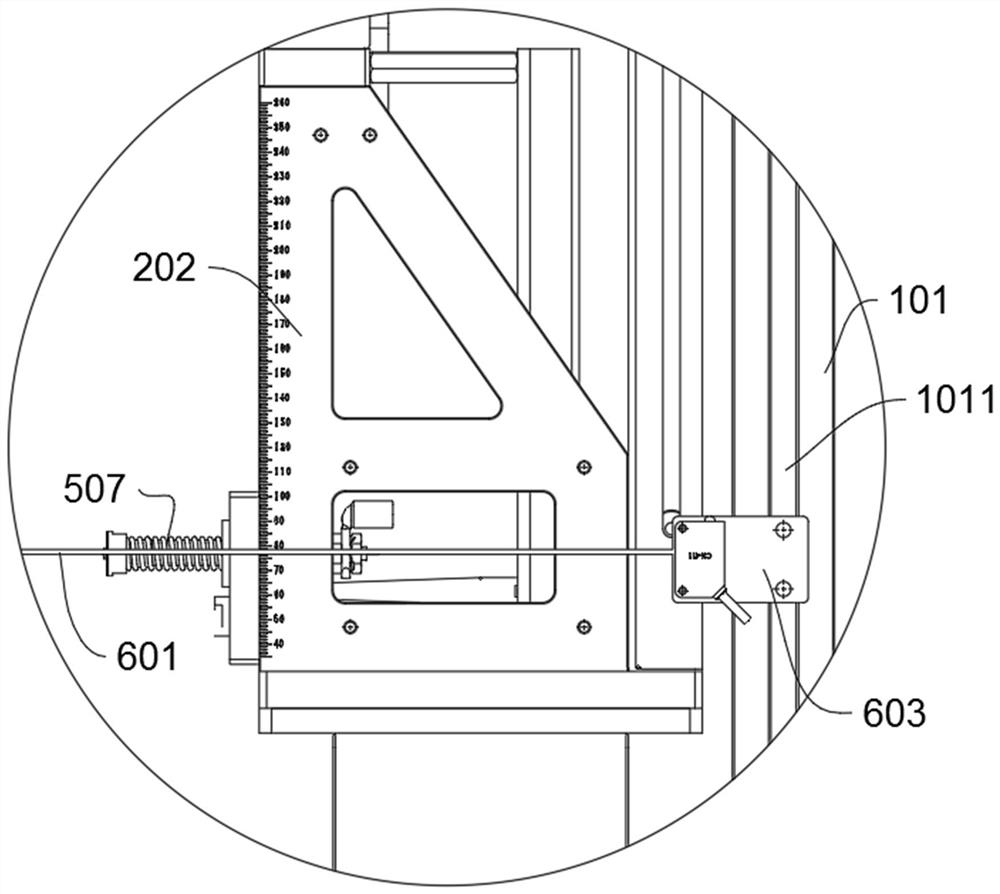

[0088] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0089] In the existing related technology, a certain current is given to the power battery in the formation process, so that the positive and negative active materials of the battery are excited, and finally the electrochemical process that makes the battery have discharge capacity. When the power battery is formed, due to the negative electrode of the power battery The potential on the side is zero, and the solvent used in the electrolyte will undergo reduction and decomposition on the surface of the negative electrode to generate gas. The positive electrode probe 207 and the negative electrode probe 507 of the needle bed used for the chemical formation process are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com