Split-type major-diameter air reverse circulation down hole hammer bottom reaming drill bit

A technology of air reverse circulation and bottom-expanding drill bit, applied in the direction of drill bit, drill pipe, drill pipe, etc., can solve the problems such as complicated structure of eccentric drill bit and eccentric drill tool with pipe reaming, unsatisfactory implementation effect and narrow scope of application. , to achieve the effect of reducing energy consumption, simple and reliable structure, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. It should be understood by those skilled in the art. The content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

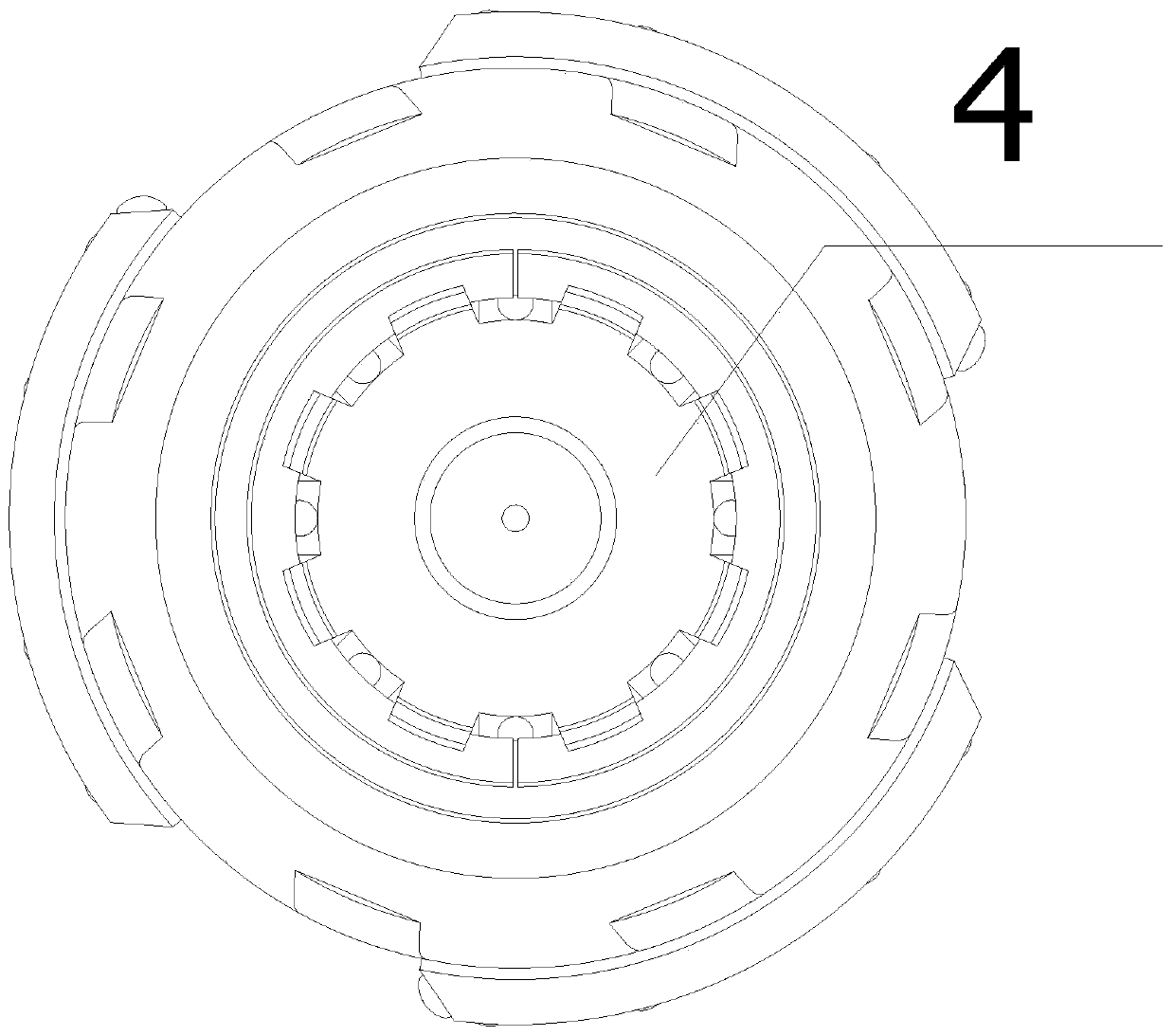

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a split-type large-diameter air reverse circulation down-the-hole hammer bottom expansion drill bit, including a bottom expansion center bit body 1, a bottom expansion drill bit bushing 2, a limit ring 3, a spline shaft 4, a spline sleeve 5, and a half ring clip The key 6, the guide flat key 7 and the drill valve 8, the limit ring 3 are fixed on the bottom expansion center drill body 1 through the positioning pin; The bottom of the center bit body 1 is threaded; the drill valve 8 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com