Deep grouting device and method

A grouting device and deep technology, applied in protection devices, buildings, infrastructure projects, etc., can solve the problems of treating the symptoms but not the root cause, inconvenient for the spread of grouting, and inability to achieve large-flow grouting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

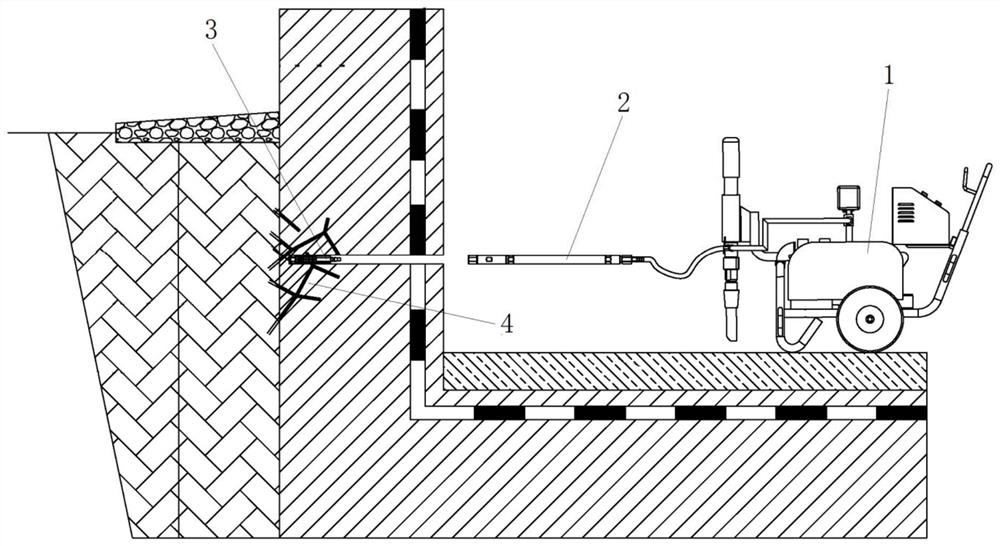

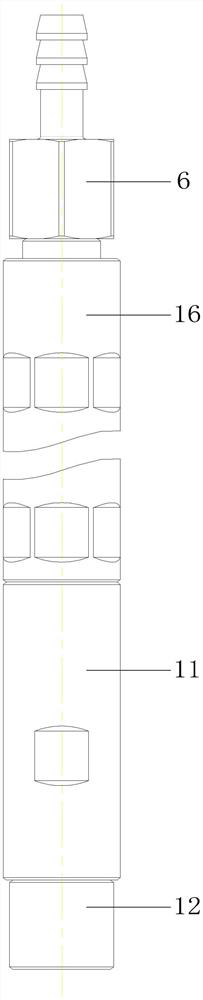

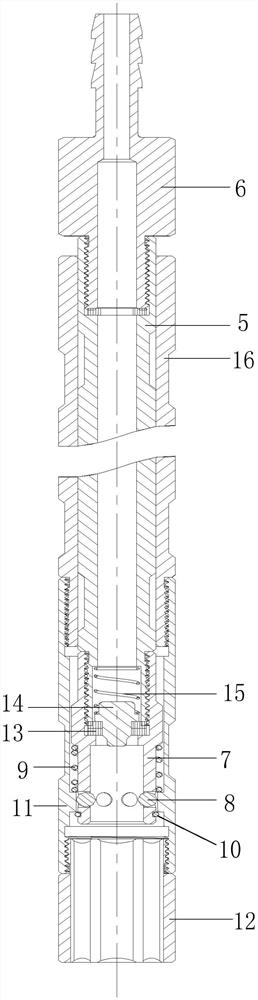

[0090] figure 1 A schematic structural diagram of a deep layer grouting device according to this embodiment is shown; figure 2 A schematic structural diagram of the adapter according to this embodiment is shown; image 3 A schematic diagram of the internal structure of the adapter according to this embodiment is shown; Figure 4 A schematic structural diagram of a grouting head according to this embodiment is shown; Figure 5 A schematic diagram of the internal structure of the grouting head according to this embodiment is shown.

[0091] Such as Figure 1 to Figure 5 As shown, the deep grouting device includes:

[0092] Grouting machine 1;

[0093] The connector 2, the connector 2 includes a connecting pipe 5 and a quick-connect female head, one end of the connecting pipe 5 is connected to the grouting machine, and the quick-connect female head is arranged at the other end of the connecting pipe 5;

[0094] Wherein, the quick-connect female head includes a quick-connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com