System for preparing LNG from oxygen-bearing coal-bed gas based on thermoacoustic technology and method

A technology of coalbed methane and technology, which is applied in the field of producing LNG from oxygen-containing coalbed methane, can solve the problems of difficult mixing refrigerant ratio, poor adaptability to variable load conditions, complicated process, etc., achieving small reserves, reducing system energy consumption, The effect of strengthening the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

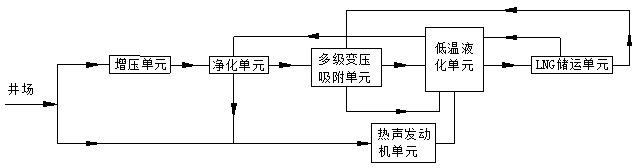

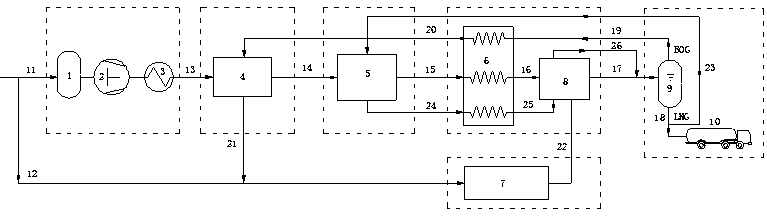

[0048] Such as figure 2 As shown, after the coalbed methane comes out of the well site, the coalbed methane used to produce the LNG part enters the surge tank 1 of the booster unit through the first pipeline 11, and then flows through the booster 2 and the cooler 3 in sequence. After pressurization and cooling, it enters the purification unit through the third pipeline 13 to remove acid gas, water and other impurities to meet the purification standard, and becomes high-pressure normal-temperature purified coalbed methane; the purified high-pressure normal-temperature coalbed methane enters through the fourth pipeline 14 In the multi-stage pressure swing adsorption unit 5, through continuous and alternate adsorption and desorption, the methane content is finally raised to the concentration of natural gas, and the concentrated coalbed gas enters the high-efficiency heat exchanger 6 of the low-temperature liquefaction unit through the fifth pipeline 15 and comes from The BOG in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com