Lifting platform used for truck loading

A technology for lifting platforms and platforms, which is applied in the direction of lifting frames and lifting devices, which can solve the problems of low stability and achieve the effect of improving stability and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

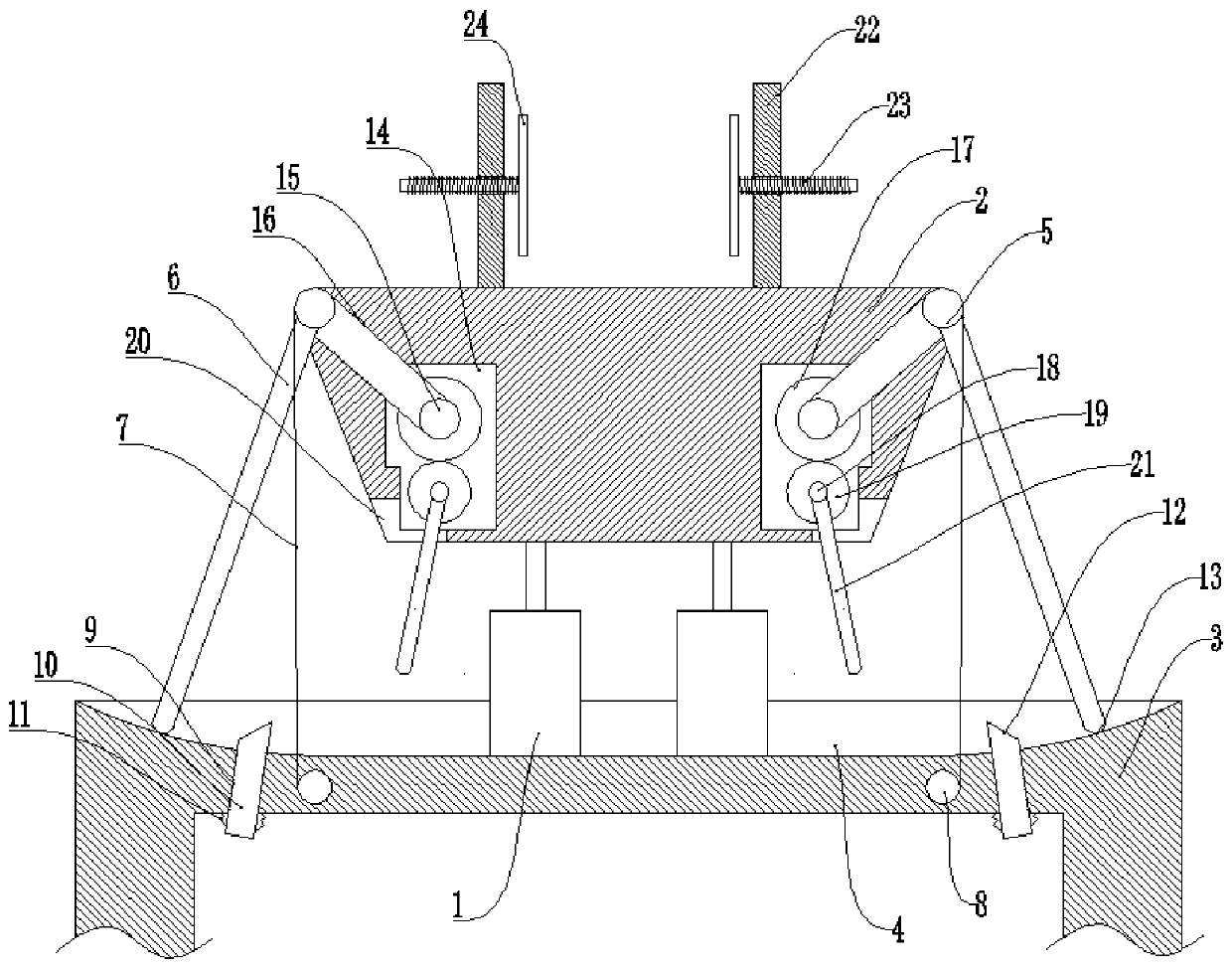

[0027] Basic as attached figure 1 Shown: the lifting platform for loading vehicles, including hydraulic cylinder 1 and platform 2, the output shaft of hydraulic cylinder 1 is fixedly connected to the bottom of platform 2. It also includes a fixed platform 3, a groove 4 is formed on the bottom of the fixed platform 3, and the hydraulic cylinder 1 is fixed in the middle of the groove 4.

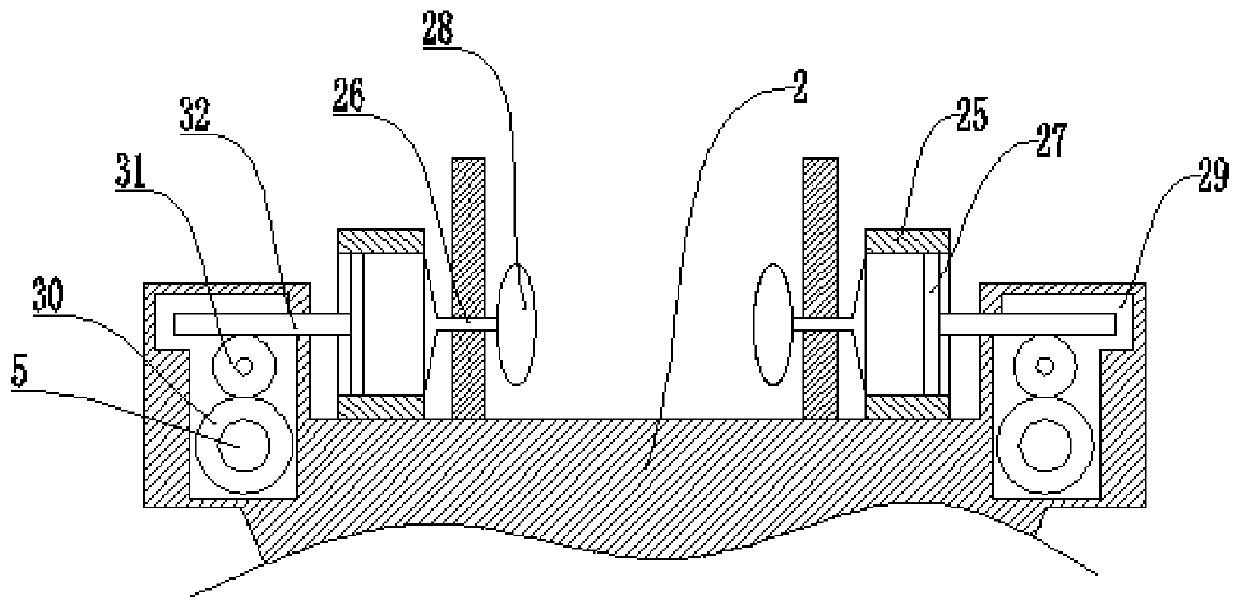

[0028] Both sides of the platform 2 are provided with a supporting mechanism for the lifting of the platform 2. The supporting mechanism includes a rotating shaft 5 connected in rotation with the platform 2 and a swing arm 6 fixed on the arc surface of the rotating shaft 5. The rotating shaft 5 and the platform 2 are fixed. A torsion spring is connected, and the rotating shaft 5 is fixedly connected with a steel wire rope 7 wound on the rotating shaft 5; the groove 4 is arc-shaped, and the swing arm 6 is located in the groove 4, and the swing track of the swing arm 6 is consistent with the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com