Heat-generating element and method for producing the same

A technology of heating element and PTC element, applied in the direction of heating element, heating element shape, electrical element, etc., to achieve the effect of improving contact, improving combination, and improving containment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

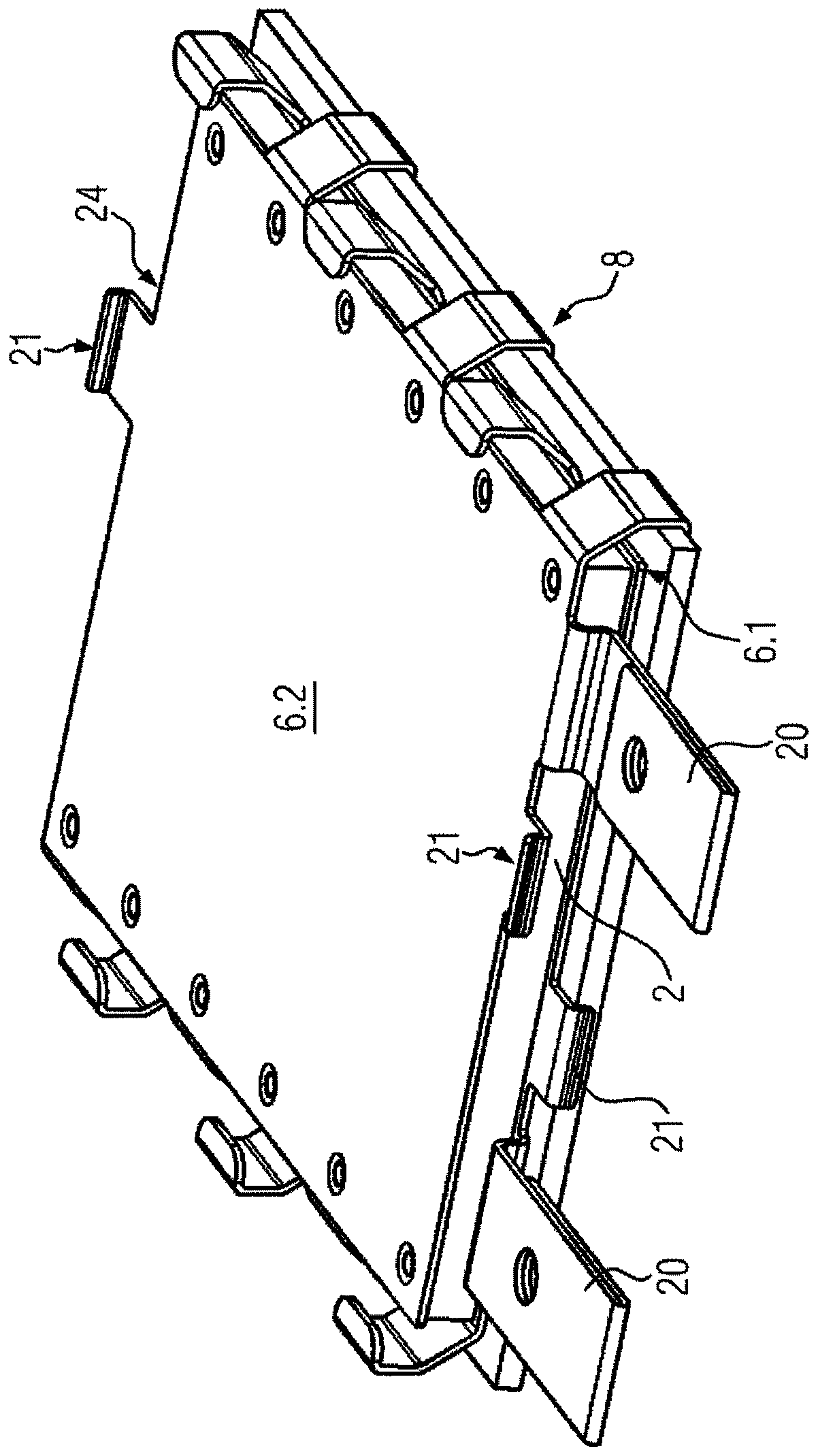

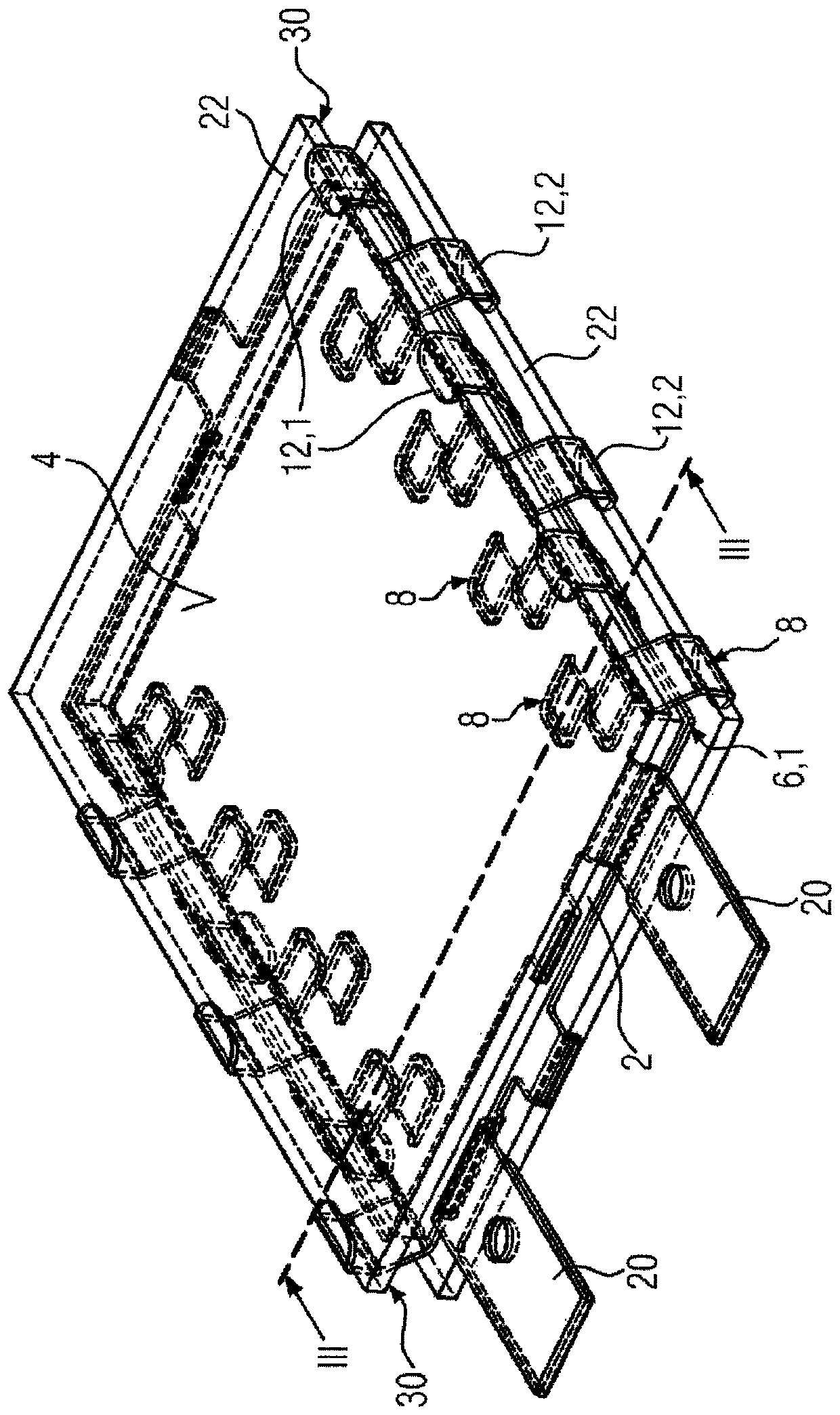

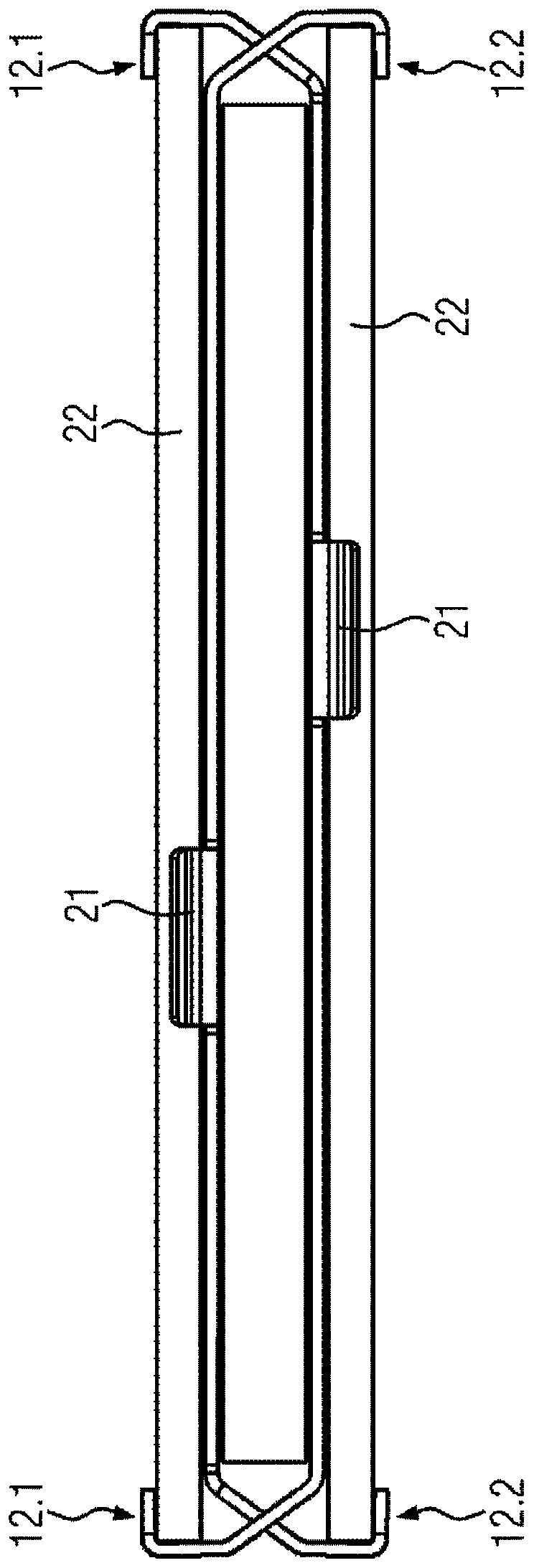

[0032] figure 1 and 2 The basic components of the heating element according to the invention are shown, which have a PTC element 2 which is electrically conductively connected with its main side 4 to a contact lug 6 . For this purpose, the contact lug 6 has a plurality of spring tongues 8 formed integrally on the contact lug 6 by punching and bending. These spring tongues 8 in figure 2 and image 3 can be regarded as sections of the contact strip 6 protruding from the contact surface 10 formed by the contact strip 6 by punching and bending, and these sections are not so much in the form of a whole area, but rather in the form of points or lines Attached to the PTC element 2.

[0033] exist Figure 1 to Figure 3 In FIG. 2 , the retaining lug 12 can also be seen, which is integrally formed on the contact piece 6 by punching and bending and protrudes beyond the contact surface 10 of the contact piece 6 , which is configured to the size of the main side 4 . Retaining tab 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com