Parallel air-cooling heat dissipation structure for stepped battery module

A battery module and heat dissipation structure technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of the decrease of the movement rate of conductive ions, the decrease of the charge and discharge capacity performance, and the impact on the service life of the battery, so as to improve the quality and energy density and volume energy density, reduce the volume of the box, and ensure the effect of temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

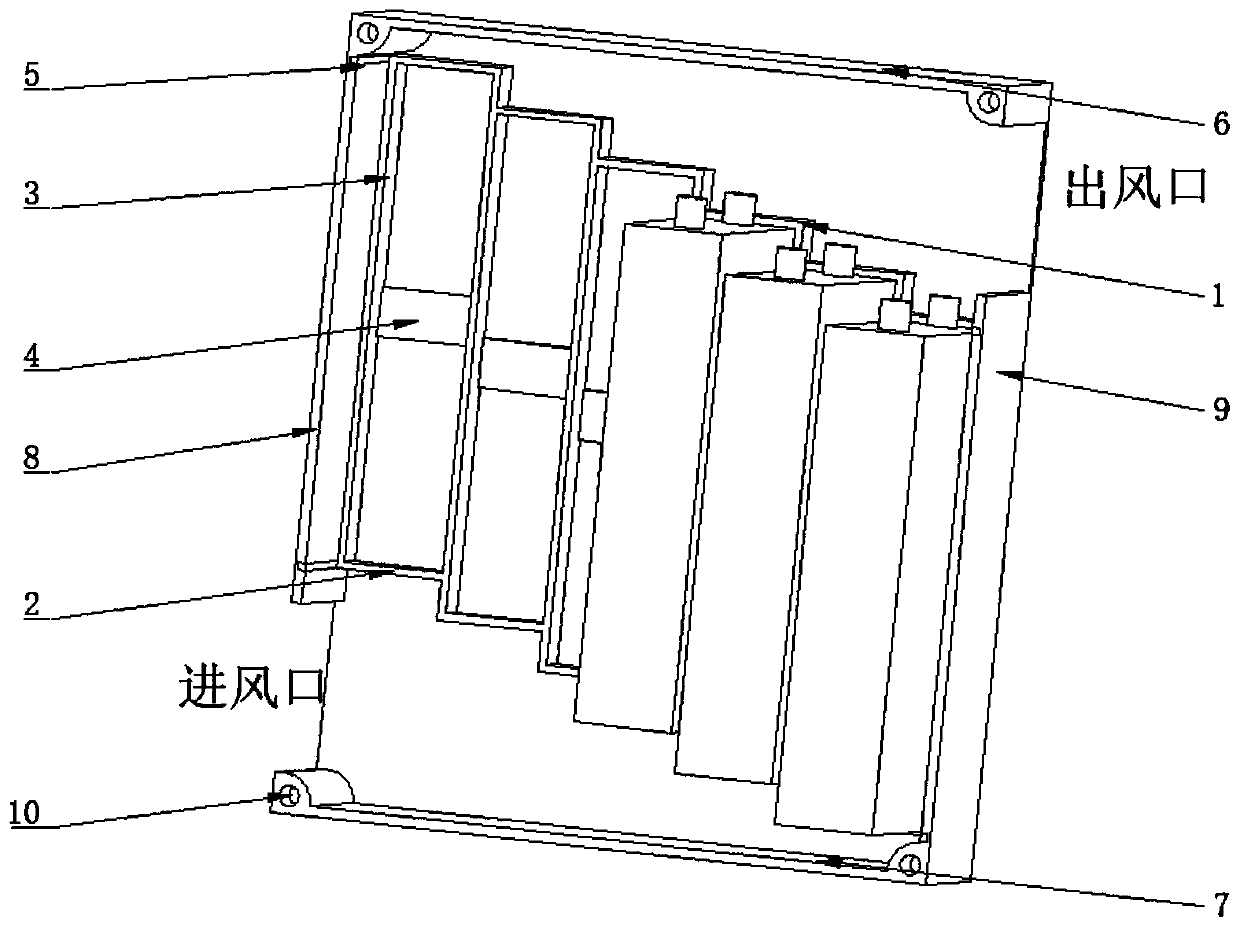

[0023] like image 3 As shown, the parallel air-cooled heat dissipation structure of the stepped battery module according to the present invention includes a heat dissipation box and a stepped frame. The stepped frame is installed in the heat dissipation box and is used to divide the heat dissipation box into air inlet areas , an air outlet area and a battery pack installation area; the battery pack installation area is provided with several battery packs installed in the ladder-shaped frame. The ladder-shaped frame is provided with several battery slots arranged in steps, and a battery pack is installed in any of the battery slots.

[0024] as attached figure 1 As shown, the ladder-shaped frame includes a left frame and a right frame; the left frame and the right frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com