Leather fabric cutting device

A fabric and cutting technology, applied in the field of luggage processing equipment, can solve the problems of poor quality and low efficiency of leather cutting, and achieve the effects of improving stability, improving efficiency and quality, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

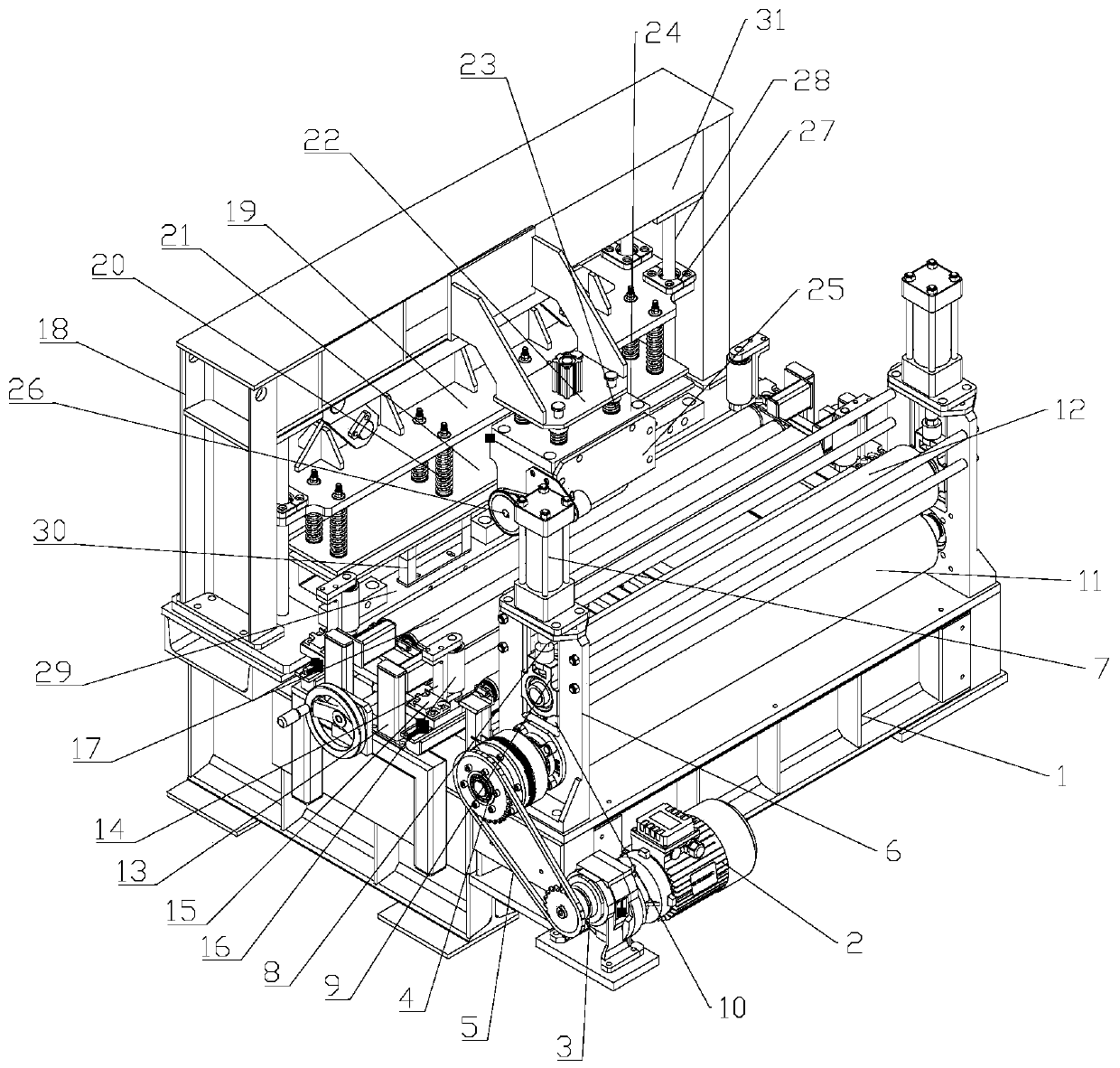

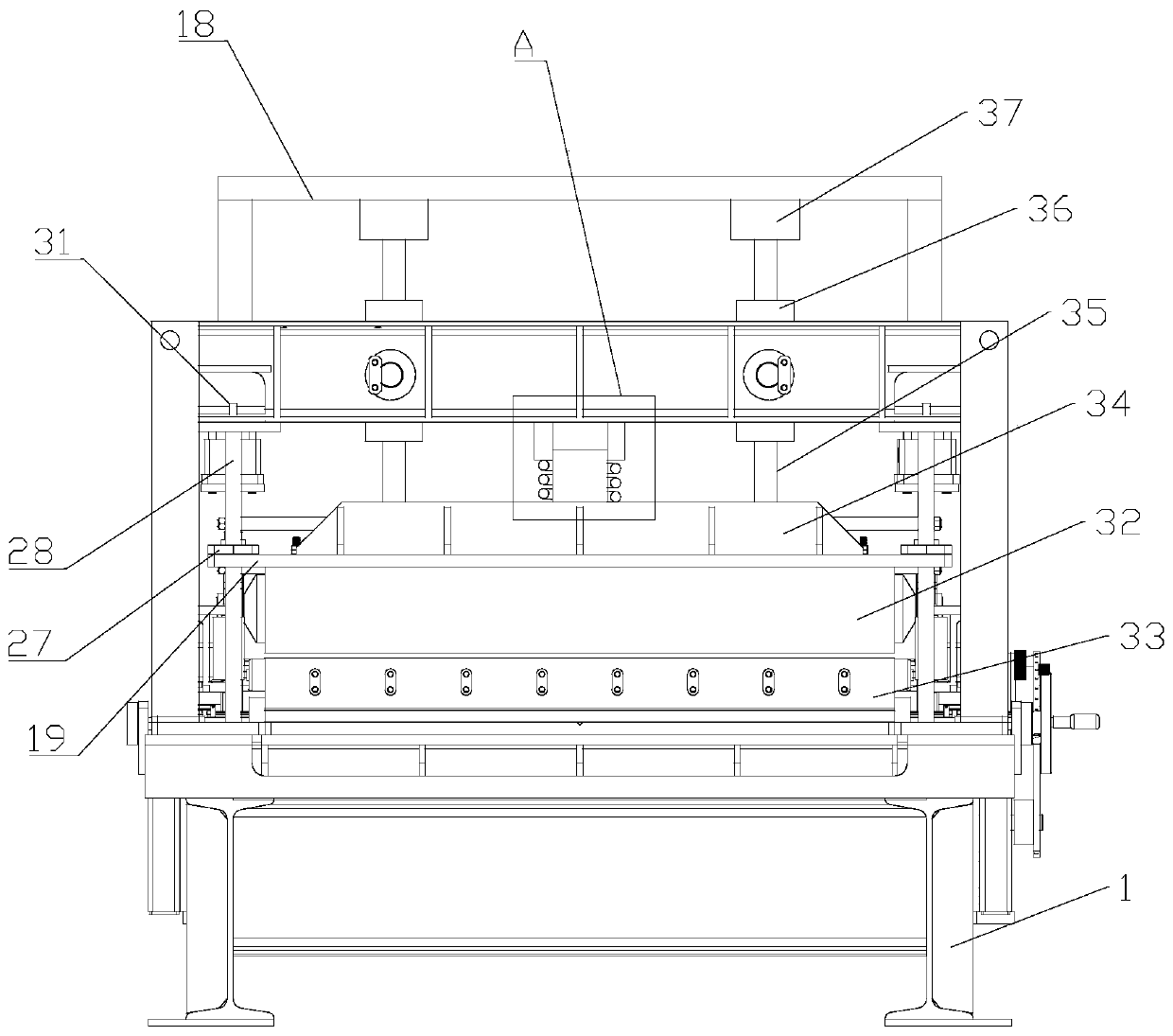

[0033] A cutting device for leather fabrics, such as Figure 1-3As shown, the installation base 1 is included, the second installation frame 6 is installed on the upper end of the installation base 1, the fifth guide wheel 11 and the fourth guide wheel 12 are installed in the second installation frame 6, and the fourth guide wheel 12 is positioned at the fifth guide wheel Above 11, the second mounting bracket 6 is provided with a chute 10, the chute 10 is provided with a slider 9 that can slide along the chute 10, the slider 9 is connected with the fourth guide wheel 12, and the slider 9 is equipped with The third hydraulic rod 8, the third hydraulic pump 7 that drives the third hydraulic rod 8 to move in the vertical direction is installed on the second mounting frame 6, and the motor 2 is also installed on the installation base 1, and the driving wheel is installed on one side of the motor 2 3. A transmission belt 5 is installed on the driving wheel 3, and a driven wheel 4 i...

Embodiment 2

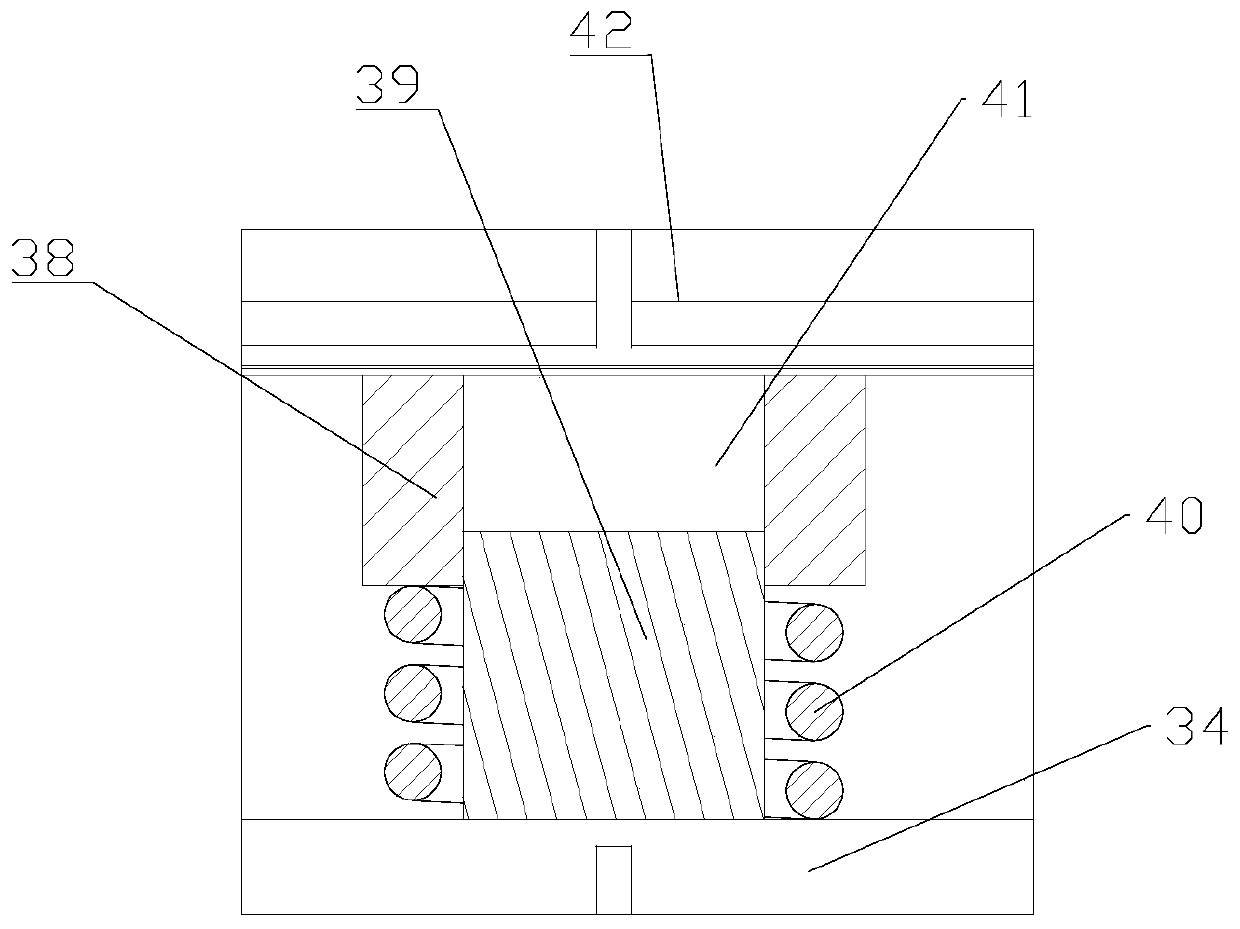

[0041] A cutting device for leather fabrics, such as Figure 4 As shown, in order to improve the efficiency and quality of leather cutting; this embodiment makes the following improvements on the basis of Embodiment 1: the first guide groove 46 is installed on the side of the cutter head dislocation plate 33 near the cutter head 32, and the cutter head 32 is provided with a first guide groove 46 that slides along the first guide groove 46 on one side of the cutter head offset plate 33 . By installing the first guide groove 46 on the side of the cutter head dislocation plate 33 near the cutter head 32, and setting the first guide groove 46 that can slide along the first guide groove 46 on the side of the cutter head 32 near the cutter head dislocation plate 33 In this way, the stability of the movement of the cutter head 32 can be effectively improved, thereby improving the stability and quality of cutting leather by the cutter head 32 .

[0042] In order to improve the effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com