A kind of regenerated cellulose fiber containing shea butter and preparation method thereof

A technology of regenerated cellulose and shea butter, which is applied in the textile field, can solve the problems of unsuitable fabrics, etc., and achieve good sun protection, high UPF value, and improved moisturizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

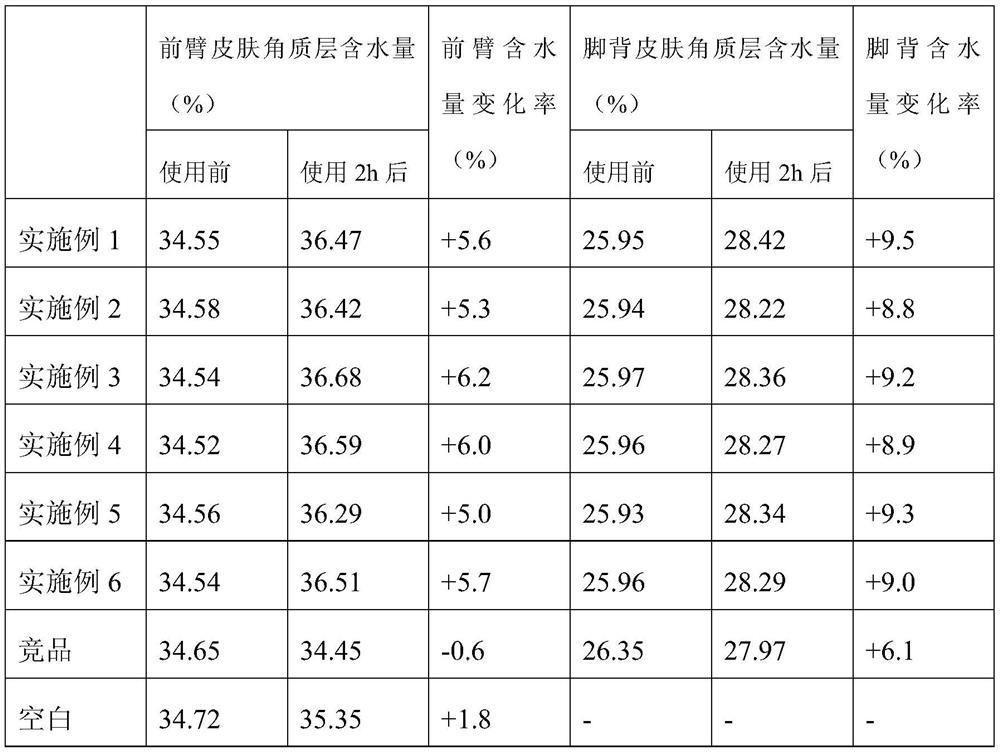

Examples

Embodiment 1

[0044] Fibers were prepared as follows:

[0045] (1) described emulsifying comprises that shea butter is added in emulsifier, be warming up to 35 ℃, stir 30min with 3500rpm, make shea butter emulsion; The mass ratio of described shea butter and emulsifier is 1:0.5, the emulsifier is a mixture of polyethoxylated isotridecanol and Tween 80, and the mass ratio of polyethoxylated isotridecanol and Tween 80 is 0.3:1;

[0046] (2) get a certain proportion of melamine and mix with formaldehyde, add deionized water to stir and adjust pH to 8.0, slowly heat up to 65°C, and stir for 30min with rotating speed 1000rpm to obtain prepolymer;

[0047] (3) the prepolymer obtained in step (2) is added dropwise to the shea butter emulsion obtained in step (1), while the stirring speed is 1300rpm, the temperature is adjusted to 60°C, and the pH is adjusted to 6.0, stir for 2h, add sodium methylene dinaphthalene sulfonate to obtain microcapsule liquid;

[0048] (4) butyl methoxy dibenzoyl metha...

Embodiment 2

[0053] Fibers were prepared as follows:

[0054] (1) described emulsifying comprises that shea butter is added in emulsifier, be warming up to 52 ℃, stir 10min with 3100rpm, make shea butter emulsion; The mass ratio of described shea butter and emulsifier is 1:0.4, the emulsifier is a mixture of polyethoxylated isotridecanol and Tween 80, and the mass ratio of polyethoxylated isotridecanol and Tween 80 is 0.4:1;

[0055] (2) get a certain proportion of melamine and mix with formaldehyde, add deionized water to stir and adjust pH to 7.8, slowly heat up to 65°C, and stir for 30min at a rotating speed of 900rpm to obtain a prepolymer;

[0056] (3) the prepolymer obtained in step (2) is added dropwise to the shea butter emulsion obtained in step (1), while the stirring speed is 1300rpm, the temperature is adjusted to 60°C, and the pH is adjusted to 4.5, stirring for 1h, adding sodium methylene dinaphthalene sulfonate to obtain microcapsule liquid;

[0057] (4) butyl methoxy dibe...

Embodiment 3

[0062] Fibers were prepared as follows:

[0063] (1) described emulsification comprises that shea butter is added in emulsifier, is warming up to 45 ℃, with 3000rpm stirring 20min, makes shea butter emulsion; The mass ratio of described shea butter and emulsifier is 1:0.5, the emulsifier is a mixture of polyethoxylated isotridecanol and Tween 80, and the mass ratio of polyethoxylated isotridecanol and Tween 80 is 0.5:1;

[0064] (2) get a certain proportion of melamine and mix with formaldehyde, add deionized water to stir and adjust pH to 8.2, slowly heat up to 65°C, and stir for 30min at a rotating speed of 800rpm to obtain a prepolymer;

[0065] (3) the prepolymer obtained in step (2) is added dropwise to the shea butter emulsion obtained in step (1), while the stirring speed is 1500rpm, the temperature is adjusted to 60°C, and the pH is adjusted to 5, stirring for 30min, adding sodium methylene bis-naphthalene sulfonate to obtain microcapsule liquid;

[0066] (4) butyl m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com