A method for constructing liquid infusion super-slip coating based on one-step method of ternary system

A ternary system and liquid infusion technology, applied in the direction of coating, wax coating, etc., can solve the problems of shortening the preparation cycle, achieve the effect of reducing the preparation cycle, reducing the limitation of complex equipment, and cheap and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

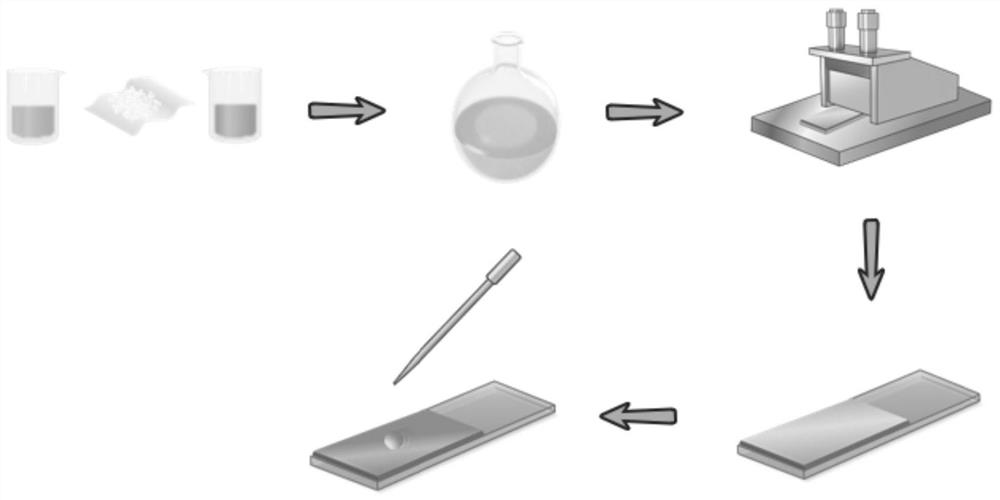

[0033] Add 10g of polypropylene with a melt index of 35g / min, 10g of silicone oil with a viscosity of 10cs, and 30g of n-hexadecane into the beaker at the same time, stir them with a rotor to disperse them evenly, heat to 200°C, and keep warm for 1.5h to completely dissolve the polypropylene to obtain Homogeneous clear solution.

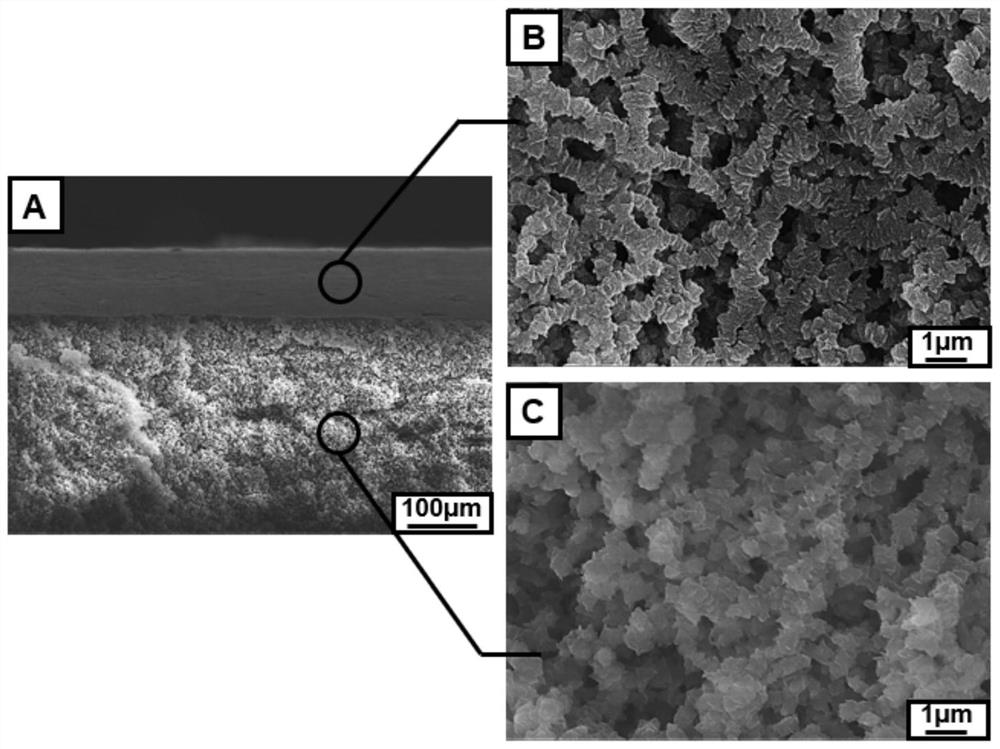

[0034] Spray the obtained solution on the glass sheet / metal substrate with a preheated spray gun, and wait for it to cool naturally to obtain a new type of liquid pouring surface coating. The electron microscope result of described coating is as figure 1 As shown, A is the cross-sectional electron microscope image of the coating, B is the high-magnification frontal electron microscope image of the coating, and C is the high-magnification cross-sectional electron microscope image of the coating; it can be observed from Figure B that there are a large number of microporous structures on the surface of the coating, combined with Figure The microporous ...

Embodiment 2

[0036] Add 10g of polypropylene with a melt index of 20g / min, 10g of silicone oil with a viscosity of 100cs, and 40g of n-hexadecane into the flask at the same time, stir with a rotor to disperse them evenly, heat to 200°C, and keep warm for 1.5h to completely dissolve the polypropylene to obtain Homogeneous clear solution.

[0037] Brush the obtained solution evenly on the glass sheet / metal substrate with a brush, and wait for it to cool naturally to obtain a new type of liquid pouring surface coating.

Embodiment 3

[0039] Add 10 g of polyethylene with a melt index of 35 g / min into the beaker and heat to 200°C until the polyethylene becomes a transparent molten state. Add 10g of silicone oil with a viscosity of 200cs and 30g of n-hexadecane to another beaker, stir with a stirrer to make them evenly mixed, add the evenly mixed solution into the beaker and keep it warm for 2h, and a homogeneous solution is formed in the flask.

[0040] Soak the glass sheet / metal substrate in the homogeneous solution, take it out after 30 seconds and wait for it to cool naturally to obtain a new type of liquid perfusion surface coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com