A kind of degradation method of acid orange II dye wastewater

A dye wastewater and acid orange technology, applied in the field of acid orange II dye wastewater degradation, can solve the problems of high cost, inability to apply industrial production, long time, etc., and achieve the effects of increasing the microscopic surface area, improving the degradation rate, and having great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

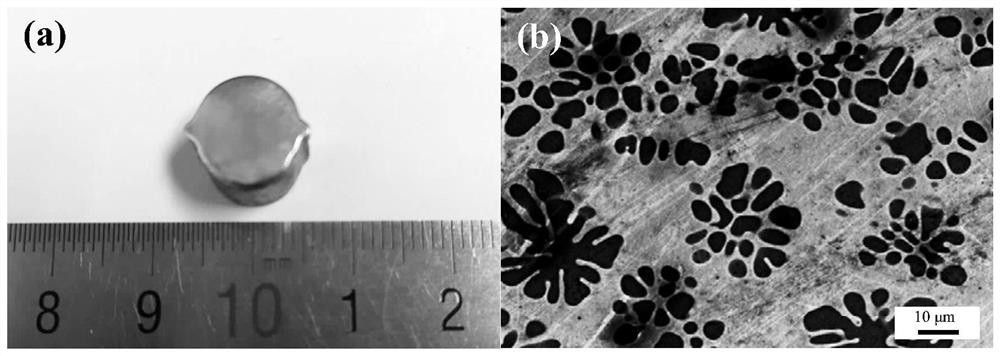

[0030] High-purity Mg (99.9%) and Zn (99.9%) are weighed according to the corresponding atomic ratio, melted in a resistance furnace, and then cast into a mold with a diameter of 10mm to cool, and prepared into Mg 78 Zn 22 Alloy ingot, its macroscopic appearance and microscopic appearance are as follows: figure 1 shown.

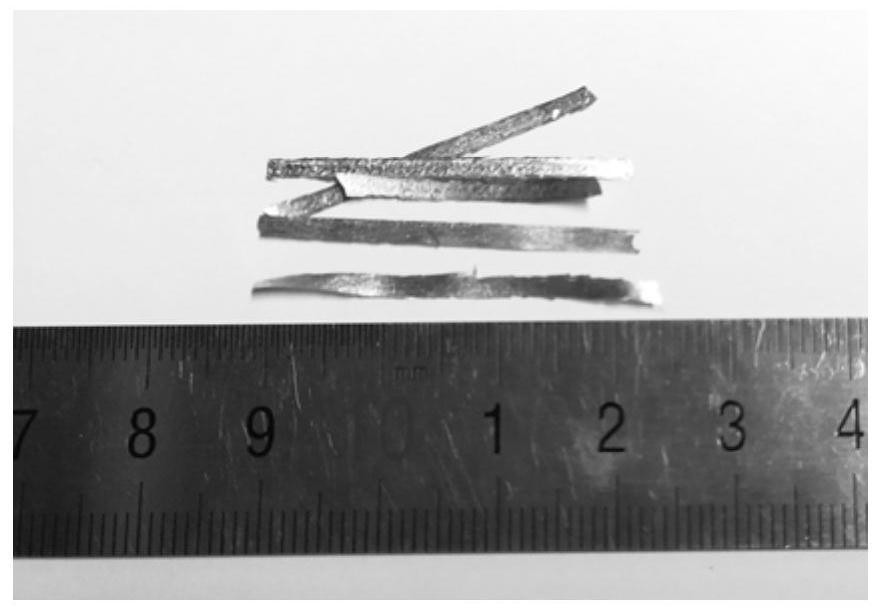

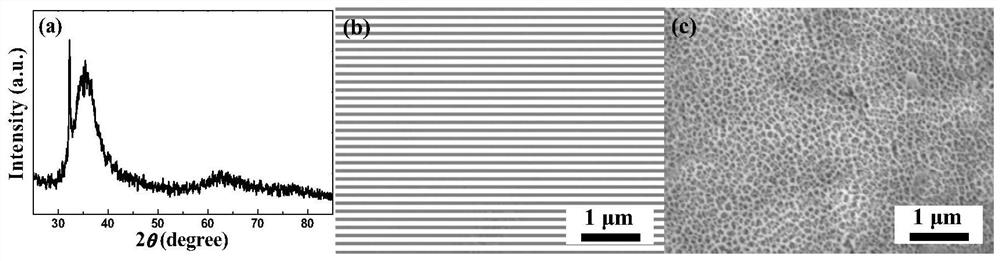

[0031] Mg 78 Zn 22 The alloy ingot is divided into small pieces of ingots with a length of 1cm for stripping, and the small pieces of ingots are placed in a quartz tube and heated and melted in an induction coil. The speed of the copper roller is 2400r / min (the line speed is 44m / s), will have melted into liquid Mg 78 Zn 22 The alloy is sprayed onto a copper roll to obtain Mg 78 Zn 22 Semi-amorphous strips, whose morphology is as figure 2 shown.

[0032] Take 500mg of citric acid granules, 50mg of Acid Orange II powder and a certain amount of concentrated hydrochloric acid, and use deionized water in a 500mL volumetric flask to prepare a citric acid...

Embodiment 2

[0041] High-purity Mg (99.9%) and Zn (99.9%) are weighed according to the corresponding atomic ratio, melted in a resistance furnace, and then cast into a mold with a diameter of 10mm to cool, and prepared into Mg 78 Zn 22 alloy ingot.

[0042] Mg 78 Zn 22 The alloy ingot is divided into small pieces of ingots with a length of 1cm for stripping, and the small pieces of ingots are placed in a quartz tube and heated and melted in an induction coil. The speed of the copper roller is 2400r / min (the line speed is 44m / s), will have melted into liquid Mg 78 Zn 22 The alloy is sprayed onto a copper roll to obtain Mg 78 Zn 22 Semi-amorphous strips.

[0043] Take 400mg of citric acid granules, 50mg of Acid Orange II powder and a certain amount of concentrated hydrochloric acid respectively, and use deionized water in a 500mL volumetric flask to prepare a citric acid solution with a concentration of 0.8g / L and a citric acid solution with a concentration of 100mg / L and pH=2. Acid...

Embodiment 3

[0048] High-purity Mg (99.9%) and Zn (99.9%) are weighed according to the corresponding atomic ratio, melted in a resistance furnace, and then cast into a mold with a diameter of 10mm to cool, and prepared into Mg 78 Zn 22 alloy ingot.

[0049] Mg 78 Zn 22 The alloy ingot is divided into small pieces of ingots with a length of 1cm for stripping, and the small pieces of ingots are placed in a quartz tube and heated and melted in an induction coil. The speed of the copper roller is 2400r / min (the line speed is 44m / s), will have melted into liquid Mg 78 Zn 22 The alloy is sprayed onto a copper roll to obtain Mg 78 Zn 22 Semi-amorphous strips.

[0050] Take 600mg of citric acid granules, 50mg of acid orange II powder and a certain amount of concentrated hydrochloric acid respectively, and use deionized water in a 500mL volumetric flask to prepare a citric acid solution with a concentration of 1.2g / L and a citric acid solution with a concentration of 100mg / L and pH=1.8. Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com