Preparation method and application of food-grade microcrystalline cellulose

A microcrystalline cellulose, food-grade technology, applied in the field of microcrystalline cellulose preparation, can solve the problems of product anti-oxidation protection, product easy to turn brown, poor anti-oxidation effect of microcrystalline cellulose products, etc., to avoid enzyme Effects of catalytic discoloration, calorie reduction, and regulation of human dietary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of food-grade microcrystalline cellulose, carried out as follows:

[0033] (1) Crushing bagasse: dry the bagasse after sugar extraction in vacuum and low temperature, and crush it into powder; dry it in vacuum at a temperature of 60-70°C, and vacuum degree of -0.08--0.10MPa, and dry it in a vacuum at low temperature The time is 1-2h; the particle size of the powder is 10-40 mesh.

[0034] (2) Desugaring: soak the powder obtained in step (1) in ethanol, and dry to obtain filter residue I; the mass concentration of ethanol is 20% to 40%, and the mass solid-to-liquid ratio of bagasse powder and ethanol is 1 : 1, soaking time is 2-3 hours.

[0035] (3) Anti-discoloration treatment: add an acidic mixed solution to the desugared filter residue I, stir evenly, soak, and dry to obtain filter residue II. The acidic mixed solution is composed of acetic acid, ascorbic acid and citric acid solution; the filtered residue I and the acidic mixed solution The add...

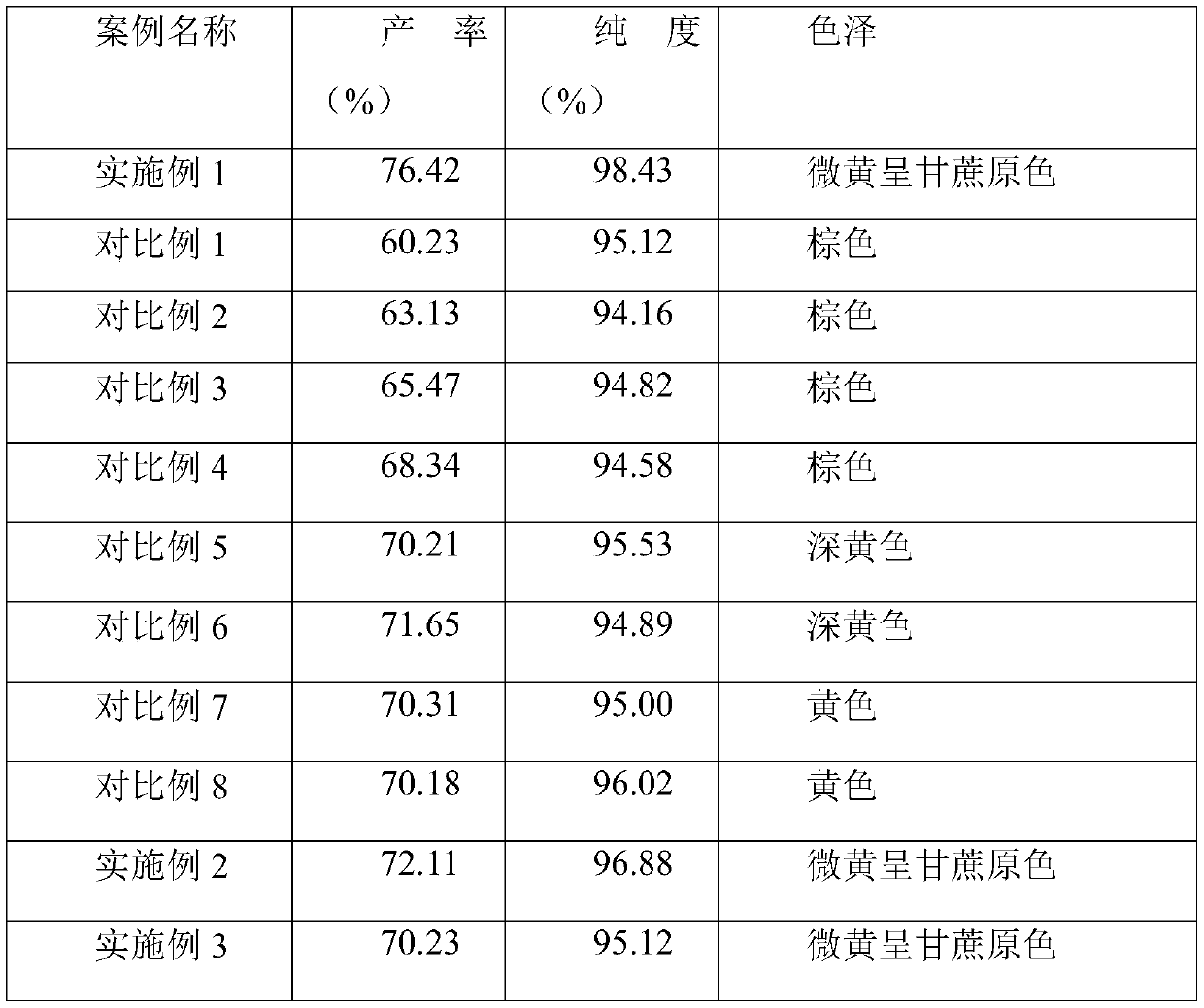

Embodiment 1

[0040] Put 250g of bagasse into a rotary evaporator with a vacuum degree of -0.10MPa and a temperature of 70°C for 2 hours, and pulverize it with a pulverizer, with a particle size of 10-40 mesh. The powder was soaked in 250ml of ethanol with a mass concentration of 40% for 3 hours, and dried to obtain filter residue I. Add 1000ml of acetic acid + ascorbic acid + citric acid mixture with a mass ratio of 1:1:1 to the filter residue I (the mass concentration of acetic acid is 5%, the mass concentration of ascorbic acid is 10%, and the mass concentration of citric acid is 10%) for soaking After 10 hours, spin dry to obtain filter residue II. Add 1250ml of 10% sodium hydroxide solution to the filter residue II, put it in a water bath at 90°C for 2 hours, take it out to cool, spin dry, and wash with a small amount of water several times while spinning dry. Add 1000ml of 4mol / L hydrochloric acid, heat to boiling, keep warm for 1.5h, let stand for 24h, and shake dry. Soak in 500ml ...

Embodiment 2

[0042] Put 250g of bagasse into a rotary evaporator with a vacuum degree of -0.09MPa and a temperature of 65°C for 1.5h, and pulverize it with a pulverizer, with a particle size of 10-40 mesh. The powder was soaked in 250ml of ethanol with a mass concentration of 30% for 2.5 hours, and dried to obtain filter residue I. Add 750ml of acetic acid + ascorbic acid + citric acid mixture with a mass ratio of 1:1:1 to the filter residue I (the mass concentration of acetic acid is 4%, the mass concentration of ascorbic acid is 7.5%, and the mass concentration of citric acid is 7.5%) and soak After 7.5 hours, spin dry to obtain filter residue II. Add 1000ml of 7.5% sodium hydroxide solution to the filter residue II, put it in a water bath at 85°C for 1.5h, take it out to cool, spin dry, and wash with a small amount of water several times while spinning dry. Add 1000ml of 3.5mol / L hydrochloric acid, heat to boiling, keep warm for 1.5h, let stand for 24h, and shake dry. Soak in 500ml of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com