Immersed liquid cooling battery pack

A liquid-cooled battery, immersion technology, applied in batteries, secondary batteries, circuits, etc., can solve the problems of poor cooling effect, slow cooling by air cooling, uneven direct cooling, etc., and achieve automatic adjustment of heat dissipation power and uniform cooling. Liquid temperature, the effect of improving temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object and technical solutions of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

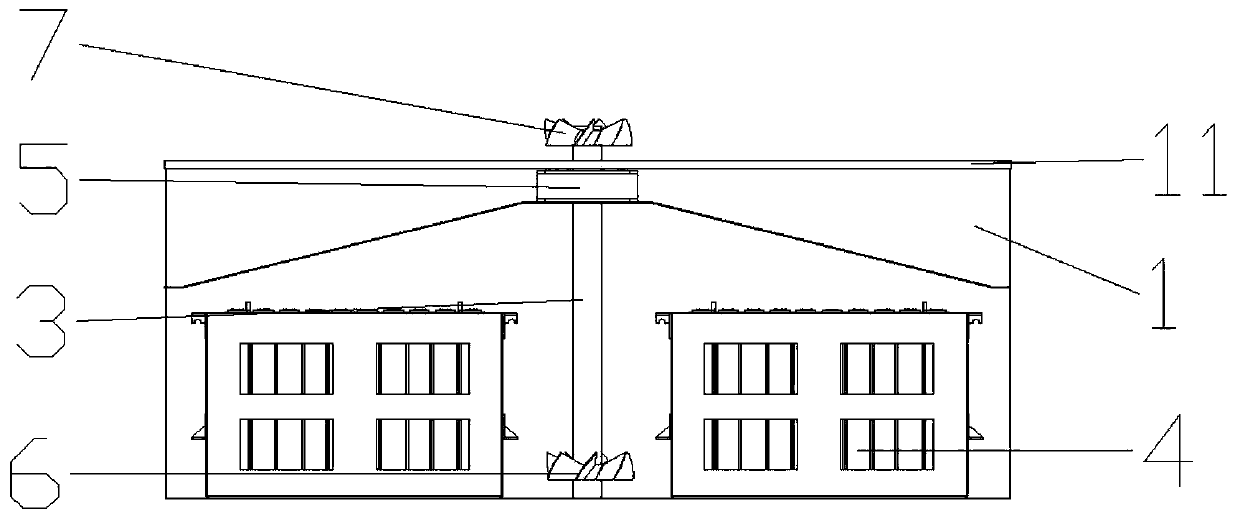

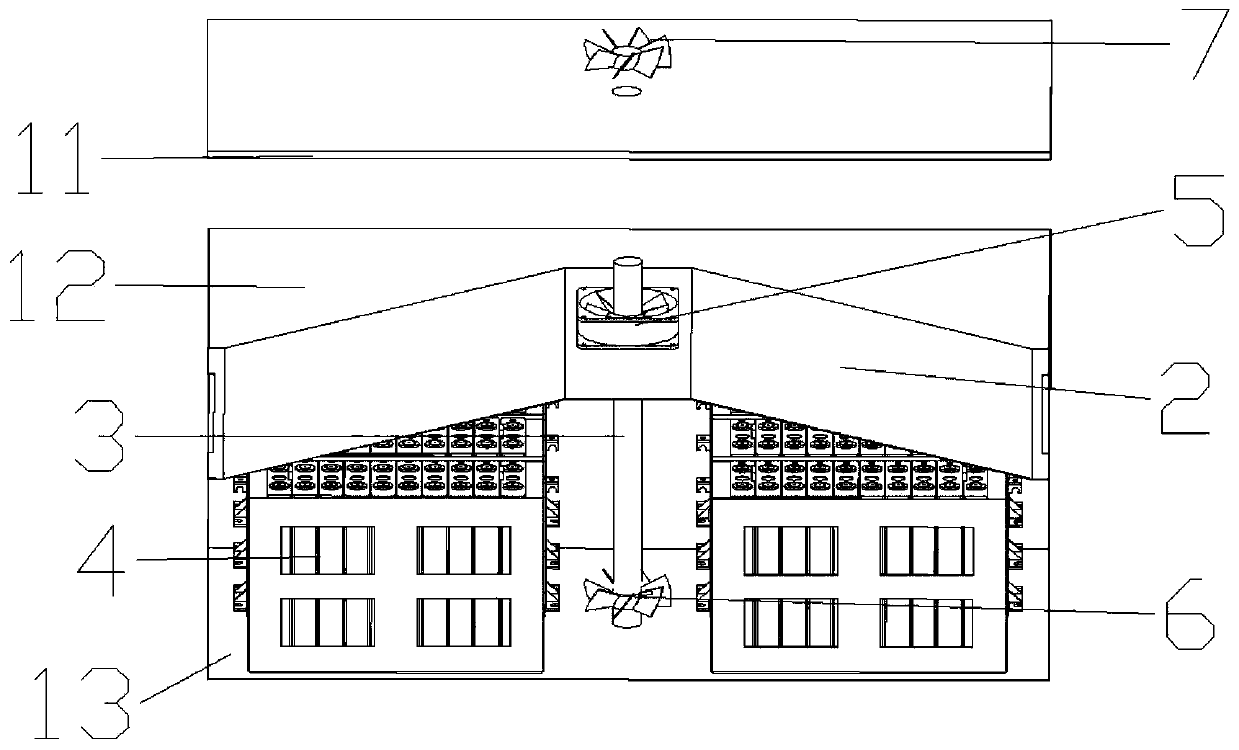

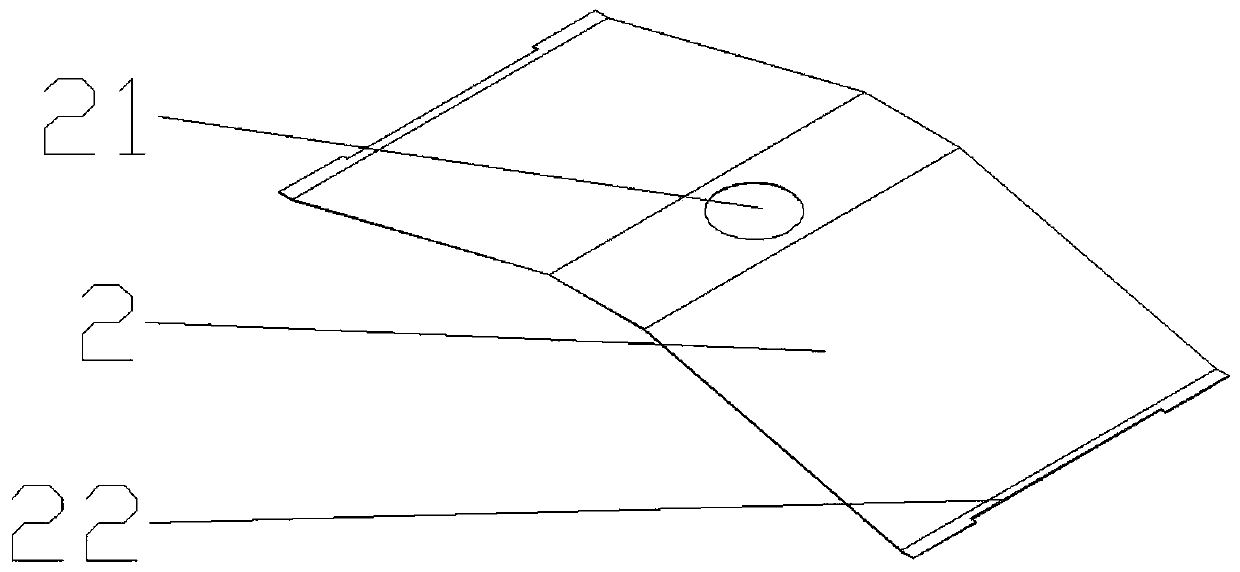

[0018] Such as Figure 1 ~ Figure 3 A submerged liquid-cooled battery pack shown includes: a case cover 11; a battery case 1 forming a sealed space with the case cover 11; a steam guide plate 2, which is a wedge-shaped plate protruding upward in the middle; installed on the battery In the middle part of the box 1, the battery box is divided into an upper box 12 and a lower box 13; a steam hole 21 is located in the middle of the steam guide plate 2, and communicates with the upper box 12 and the lower box 13; the leakage tank 22 has a total Two, respectively arranged on both sides of the steam guide plate 2, communicating with the upper box 12 and the lower box 13; the battery 4 is installed and fixed in the lower box 13; the cooling liquid is injected into the lower bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com