Push-against type rotation guiding tool

A technology of rotary steering and tools, which is applied in directional drilling and other directions, can solve problems such as poor reliability, poor system reliability, and damage to electronic control components, and achieve the effect of high overall reliability and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

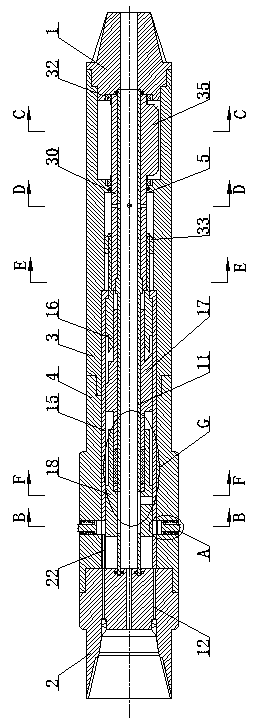

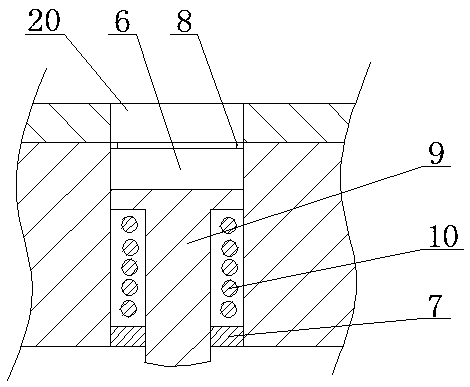

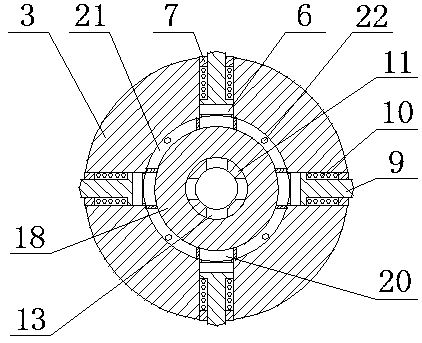

[0038] The push-to-type rotary guide tool is composed of an outer shell, an upper joint 1, a lower joint 2 and a rotation control device. The outer shell is composed of an upper shell 3 and a lower shell 4 that are screwed to each other. The central hole of the upper shell 3 is The diameter-reducing hole, the inner wall of the upper housing 3 is provided with a sealing flange 5, the lower housing 4 is in the shape of a diameter-reducing cylinder, and the large-diameter section of the lower housing 3 is evenly distributed with radially protruding holes 6 at 90 degrees. The inner wall of one end of the radially protruding hole 6 is equipped with an assembly ring 7, and the other end of the radially protruding hole 6 is provided with a limit flange 8 on the inner wall of the other end, and the radial protruding hole between the limit flange 8 and the assembly ring 7 A thrust rod 9 is installed in the 6, and the function of the limit flange 8 is to prevent the thrust rod 9 from sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com