Structure and construction method of a steel-concrete composite structure aqueduct

A combined structure and concrete technology, applied in artificial waterways, water conservancy projects, buildings, etc., can solve problems such as limited effects and difficult construction, and achieve the effect of reducing construction difficulty, improving construction quality, and easily ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, structure of the present invention, construction process are further described as follows:

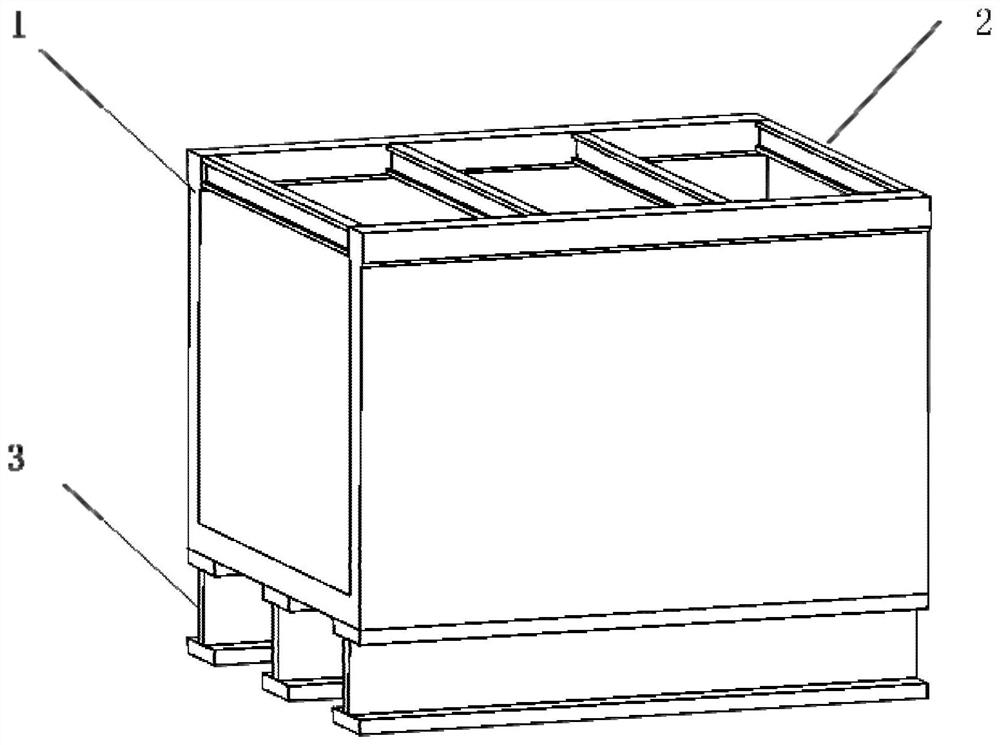

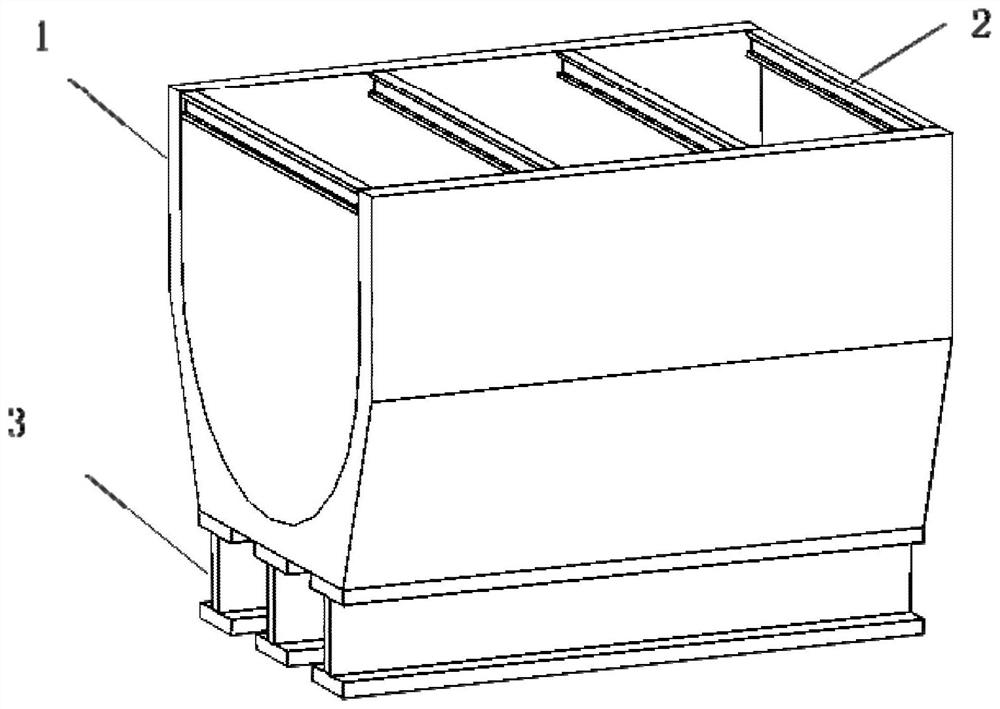

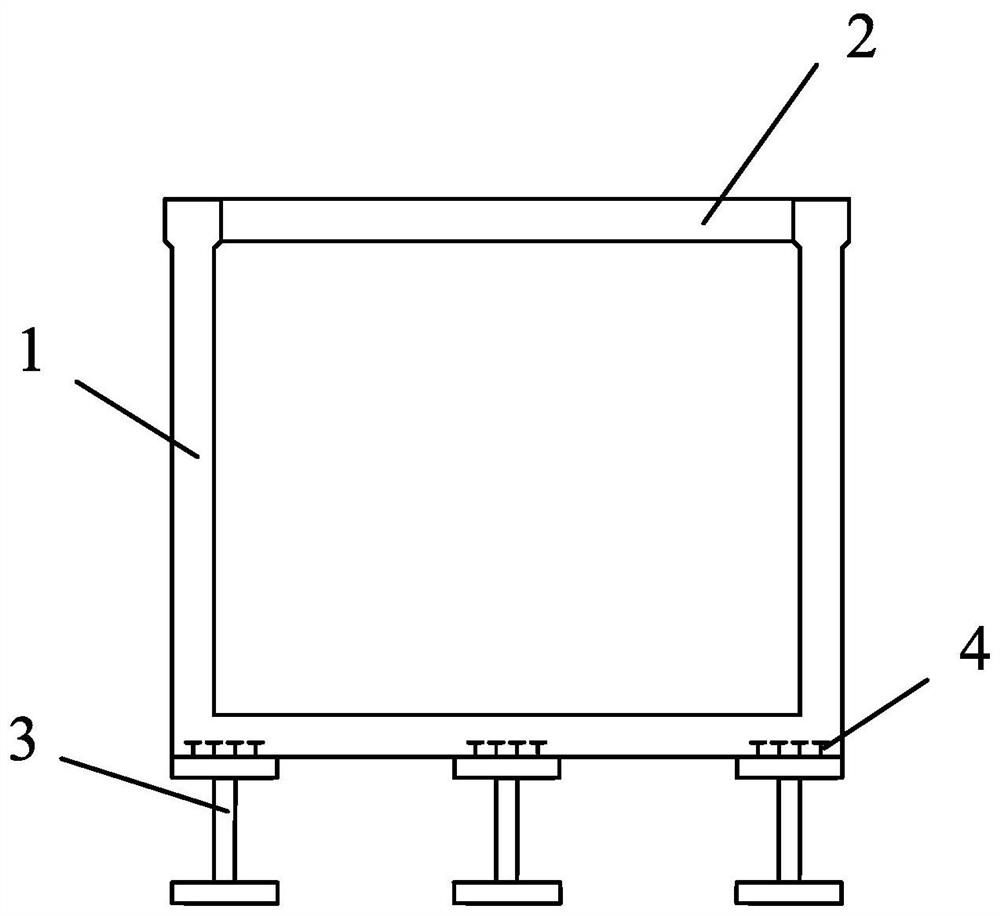

[0030] Such as figure 1 and figure 2 As shown, the structure and construction method of a steel-concrete combined structure aqueduct of the present invention includes an upper concrete tank body 1, a steel tie rod 2 at the top of the tank body and a lower steel beam 3; the upper concrete tank body 1 adopts a rectangular or U-shaped section : When using a rectangular section, such as figure 1 As shown, the tank body 1 is composed of a horizontal bottom plate and vertical side walls on both sides. When a U-shaped cross-section is adopted, such as figure 2 As shown, the tank body 1 is composed of an arc-shaped bottom plate and vertical side walls on both sides. The outside of the arc-shaped bottom plate is a horizontal structure for connecting the lower steel beam 3; The top of the side wall of the tank 1 is connected and arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com