A kind of knitting process of elastic wool knitted fabric

A fabric and process technology, applied in the field of elongation wool knitted fabric weaving technology, can solve the problems of affecting the comfort and durability of wool knitted fabrics, difficult to obtain wool knitted fabric products, and insufficient elasticity of finished products, and achieve good coverage knitting performance, Avoid the phenomenon of bottom exposure, and the effect of good uprightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

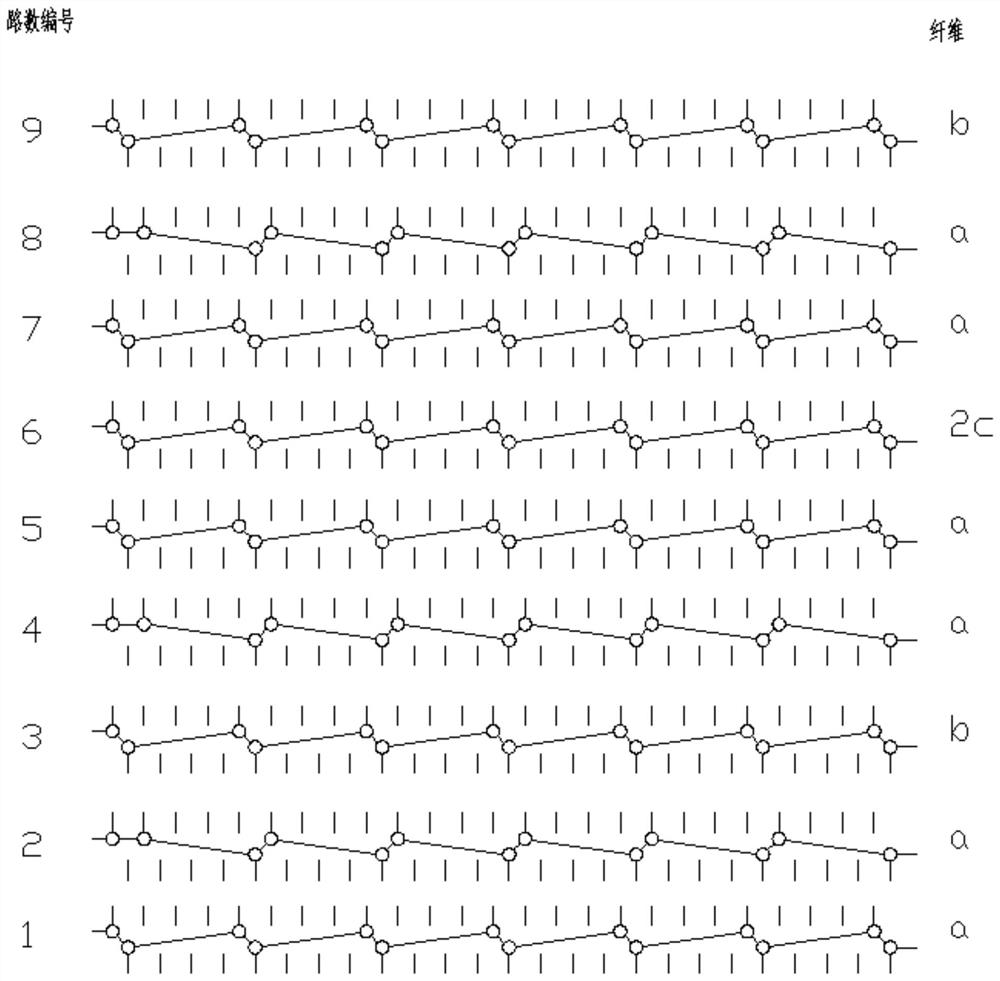

[0031] A knitting process for elastic wool knitted fabrics, the weaving process is as follows:

[0032] (1) Foaming: soak the woolen yarn in the foaming liquid and then dry it;

[0033] The bubble silk liquid is composed of softener AE504, amino silicone oil JF-810H, humectant DH-C540, penetrant JFC and water in a mass ratio of 5:4:2:1:100. The soaking temperature is 65°C and the soaking time is 30min;

[0034] (2) Yarn feeding: Send wool yarn and high elastic fiber to the knitting area of the knitting machine;

[0035] The yarn feeding tension of the wool yarn is 3.8cN when the front loop is knitted, the yarn feeding tension of the wool yarn is 2.1cN when the reverse loop is knitted, and the yarn feeding tension of the high elastic fiber is 4.9cN;

[0036] (3) Knitting back: The knitting accessories of the knitting machine include the knitting sinker and the holding sinker. The nose of the holding sinker is higher and longer than the nose of the knitting sinker. The knitt...

Embodiment 2

[0048] A knitting process for elastic wool knitted fabrics, the weaving process is as follows:

[0049] (1) Foaming: soak the woolen yarn in the foaming liquid and then dry it;

[0050] The bubble silk liquid is composed of softener AE504, amino silicone oil JF-810H, humectant DH-C540, penetrant JFC and water in a mass ratio of 5:4:2:1:100. The soaking temperature is 62°C and the soaking time is 38min;

[0051] (2) Yarn feeding: Send wool yarn and high elastic fiber to the knitting area of the knitting machine;

[0052] The yarn feeding tension of the wool yarn is 4.9cN when the front loop is knitted, the yarn feeding tension of the wool yarn is 3.1cN when the reverse loop is knitted, and the yarn feeding tension of the high elastic fiber is 6cN;

[0053](3) Knitting back: The knitting accessories of the knitting machine include the knitting sinker and the holding sinker. The nose of the holding sinker is higher and longer than the nose of the knitting sinker. The knitting...

Embodiment 3

[0065] A knitting process for elastic wool knitted fabrics, the weaving process is as follows:

[0066] (1) Foaming: soak the woolen yarn in the foaming liquid and then dry it;

[0067] The bubble silk liquid is composed of softener AE504, amino silicone oil JF-810H, humectant DH-C540, penetrant JFC and water in a mass ratio of 5:4:2:1:100. The soaking temperature is 63°C and the soaking time is 20min;

[0068] (2) Yarn feeding: Send wool yarn and high elastic fiber to the knitting area of the knitting machine;

[0069] The yarn feeding tension of the wool yarn is 3.6cN when the front loop is knitted, the yarn feeding tension of the wool yarn is 3.4cN when the reverse loop is knitted, and the yarn feeding tension of the high elastic fiber is 4.6cN;

[0070] (3) Knitting back: The knitting accessories of the knitting machine include the knitting sinker and the holding sinker. The nose of the holding sinker is higher and longer than the nose of the knitting sinker. The knitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com