A kind of rare earth vanadate film and its preparation method and application

A rare-earth vanadate and rare-earth nitrate technology, applied in chemical instruments and methods, discharge tubes, luminescent materials, etc., can solve the problem of poor adhesion and uniformity of vanadate powder and glass substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

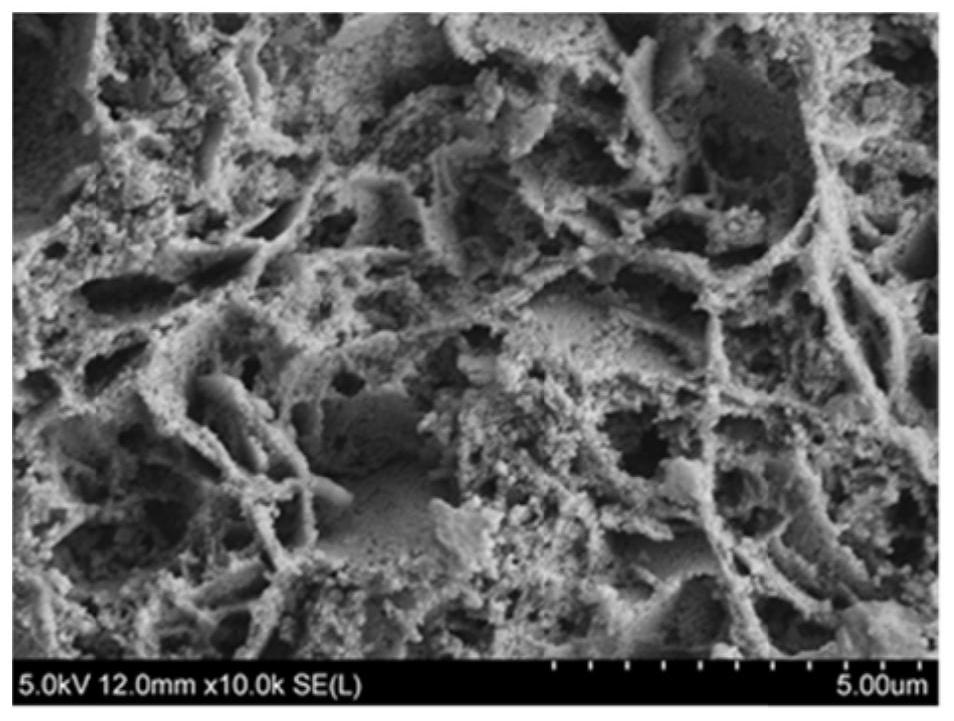

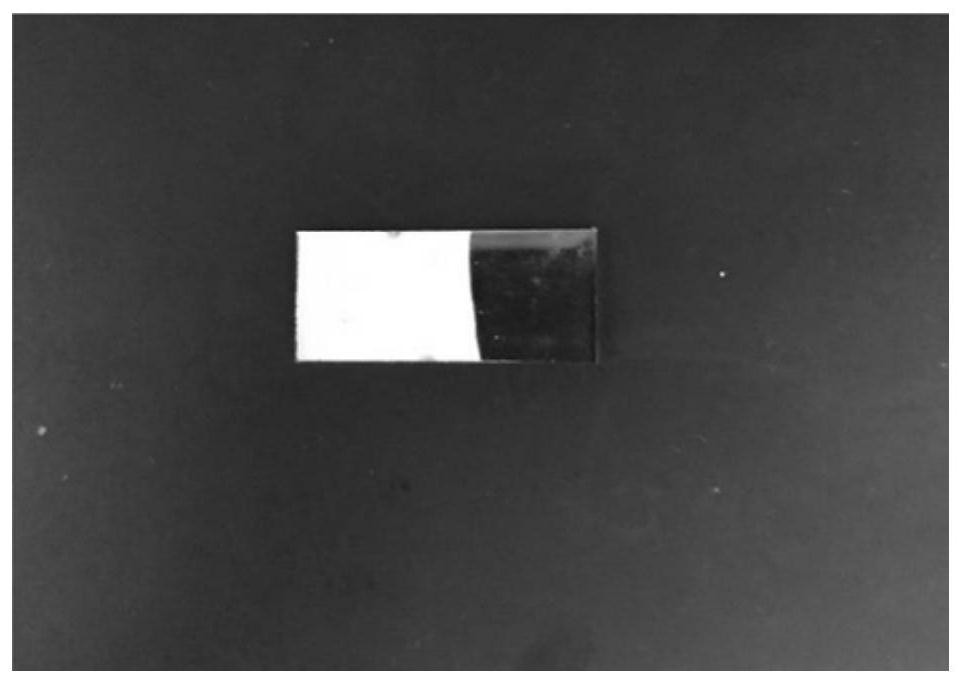

Image

Examples

preparation example Construction

[0046] The invention provides a method for preparing a rare earth vanadate thin film, comprising the following steps:

[0047] Using the aqueous solution of rare earth nitrate as the electrodeposition solution, the rare earth layered hydroxide film was prepared by pulse voltage deposition method;

[0048] After mixing the metavanadate and water, the pH value is adjusted to 7-12 to obtain a metavanadate solution;

[0049]The rare earth layered hydroxide film is immersed in the metavanadate solution to carry out replacement reaction to obtain the rare earth vanadate film.

[0050] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0051] The invention uses the aqueous solution of rare earth nitrate as the electrodeposition solution, and adopts the pulse voltage deposition method to prepare the rare earth layered hydroxide film. In the present invention, the preparation ...

Embodiment 1

[0069] (1) Eu(NO 3 ) 3 ·6H 2 O was dissolved in deionized water, and heated to 55°C in a water bath to obtain an electrodeposition solution with a concentration of rare earth metal ions of 0.1mol / L;

[0070] (2) Insert the three-electrode system into the electrodeposition solution, adopt the pulse voltage deposition method, set the deposition voltage to -0.9V, deposit at this voltage for 1.5min, repeat 4 times with an interval of 20s, and set the deposition voltage to - 1V, after depositing at this voltage for 2min, repeat 3 times at an interval of 10s, and the total deposition time is 12min, deposit a thin film on the working electrode material to obtain an electrodeposited thin film; the working electrode of the three-electrode system is ITO glass, and the auxiliary electrode It is a Pt mesh, and the reference electrode is Ag / AgCl / Cl - ;

[0071] (3) The electrodeposited film was washed sequentially with deionized water and absolute ethanol, and dried in a blast drying o...

Embodiment 2

[0078] (1) Nd(NO 3 ) 3 ·6H 2 O was dissolved in deionized water and heated to 20°C in a water bath to obtain an electrodeposition solution with a concentration of rare earth metal ions of 1 mol / L;

[0079] (2) Insert the three-electrode system into the electrodeposition solution, adopt the pulse voltage deposition method, set the deposition voltage to -1.1V, deposit at this voltage for 2 minutes, repeat 4 times with an interval of 20s, and set the deposition voltage to -1.3 V, after depositing at this voltage for 2min, repeat 3 times at an interval of 10s, the total deposition time is 14min, deposit a thin film on the working electrode material to obtain an electrodeposited thin film; the working electrode of the three-electrode system is ITO glass, and the auxiliary electrode It is a Pt mesh, and the reference electrode is Ag / AgCl / Cl - ;

[0080] (3) The electrodeposited film was washed sequentially with deionized water and absolute ethanol, and dried in a blast drying ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com