Method for heating pyridine salt B3 to prompt chlorination reaction

A technology of chlorination reaction and chlorination reaction kettle, which is applied in the field of pyridine salt production of raw materials, can solve the problems of low heat exchange efficiency, easy scaling of equipment, poor energy utilization rate, etc., achieve high heat exchange efficiency and eliminate potential safety hazards , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

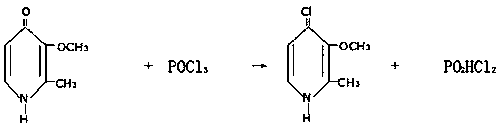

[0021] 1. Add 2100Kg of methylene chloride into the chlorination reactor, then add 700Kg of 3-methoxy-2-methyl-4-pyridone dry product into the chlorination reactor in 3 batches to fully dissolve, The temperature does not exceed 35°C to prepare 3-methoxy-2-methyl-4-pyridone solution; pump 2800Kg of phosphorus oxychloride into the high-level tank, and then drop (400kg / h) into the reaction kettle with 3 -Methoxy-2-methyl-4-pyridone solution reacts;

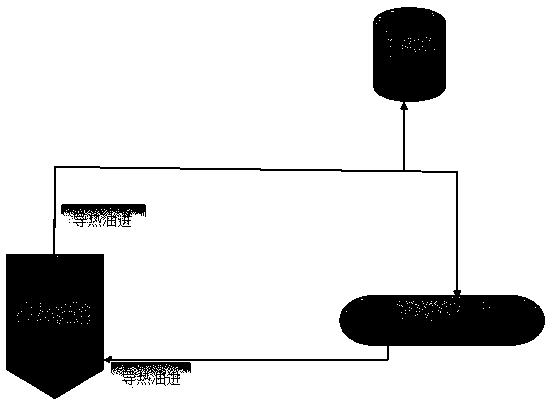

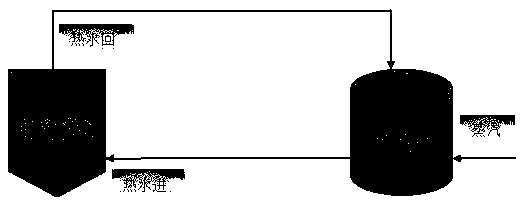

[0022] 2. Inject heat-conducting oil into the heat-conducting oil heating system. The amount of oil should be enough to ensure its own closed-circuit circulation. Turn on the heat-conducting oil circulation pump to ensure that the oil passage passes through the chlorination reactor unimpeded, and ensure that the oil pressure is at 0.3MPa. Turn on the electric heater to Heat the heat-conducting oil to the set temperature of 90°C, use the heat-conducting oil to heat the chlorination reactor to 80°C, reflux and keep warm for 8 hours, op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com