Water supply and drainage pipe head connecting mold, method, product and preparation method

A technology for water supply and drainage pipes and pipe heads, which is applied in the field of pipe head connection molds for water supply and drainage pipes, and can solve problems such as ground subsidence, damage, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

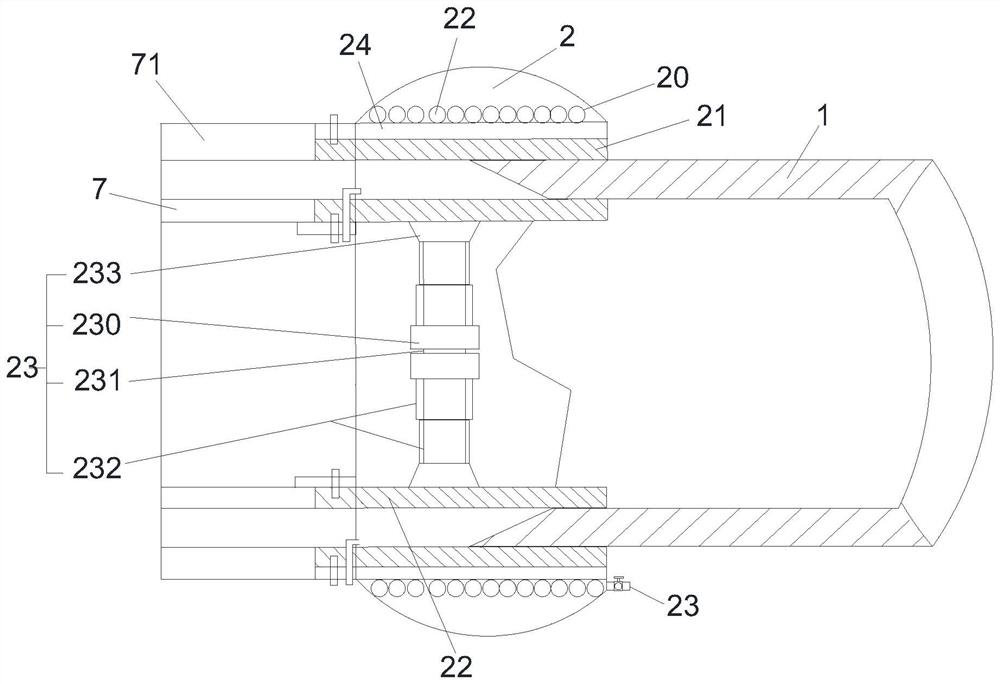

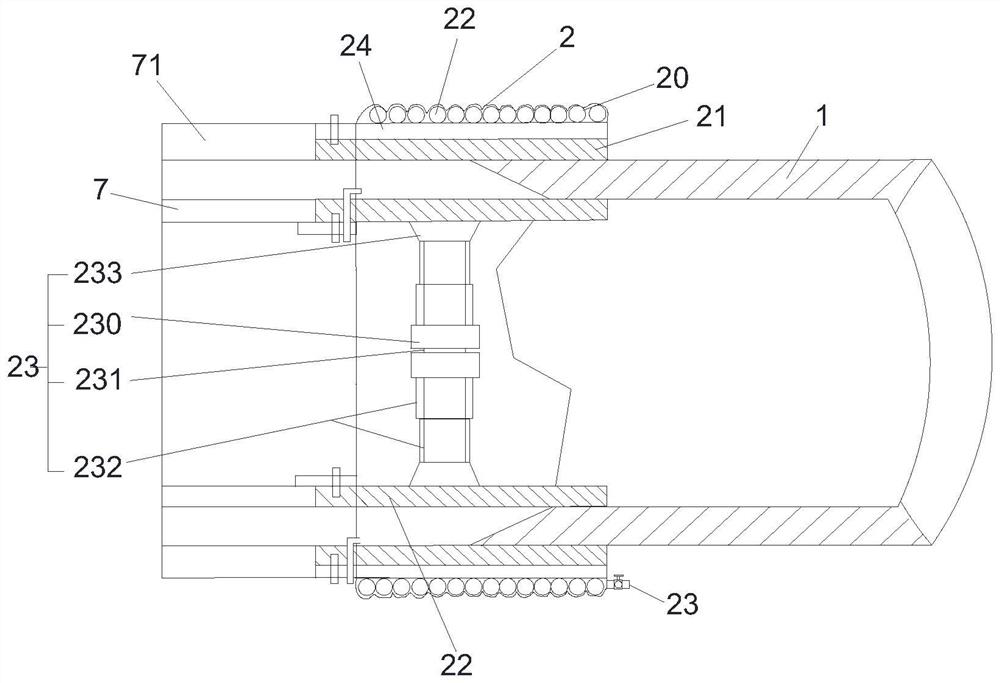

[0077] A water supply and drainage pipe head connecting mold is used to fill and level the ends of the uneven water supply and drainage pipe heads 1 when connecting two water supply and drainage pipe heads 1, such as figure 1 shown, including

[0078] The vacuum tank 210, the first side of the vacuum tank 210 is concave, and the first side of the concave is connected with the end of the water supply and drainage pipe head 1, specifically, the water supply and drainage pipe head 1 is deeply embedded in the first side of the depression, and the vacuum tank 210 is used for In a negative pressure state, the water supply and drainage pipe head 1 is clamped, fixed for a second time, and the end of the water supply and drainage pipe head 1 is filled.

[0079] The support assembly 23 is arranged in the vacuum tank 210, the support assembly 23 is connected with the inner wall of the vacuum tank 210, the support assembly 23 withstands the inner wall of the vacuum tank 210, and the suppo...

Embodiment 2

[0109] A method of using a mold for connecting the head of a water supply and drainage pipe, such as Figure 4 As shown, it is used to make the connector of the water supply and drainage pipe head 1, including

[0110] With a preset length, the end of the water supply and drainage pipe head 1 penetrates into the cavity formed by the inner cylinder 22 and the outer cylinder 21 . The preset length is the preset length of the pipe head 1 of the water supply and drainage pipe penetrating into the cavity.

[0111] The water supply and drainage pipe head 1 is respectively connected with the inner cylinder 22 and the outer cylinder 21 .

[0112] Rotate the telescopic member 232 to connect the surface of the support table 233 with the inner wall of the inner cylinder 22 to support the inner cylinder 22 .

[0113] The fastener 230 is rotated to fix the spatial position of the telescopic element 232 in the inner cylinder 22 .

[0114] Open the vacuum valve 20 to extract the air in th...

Embodiment 4

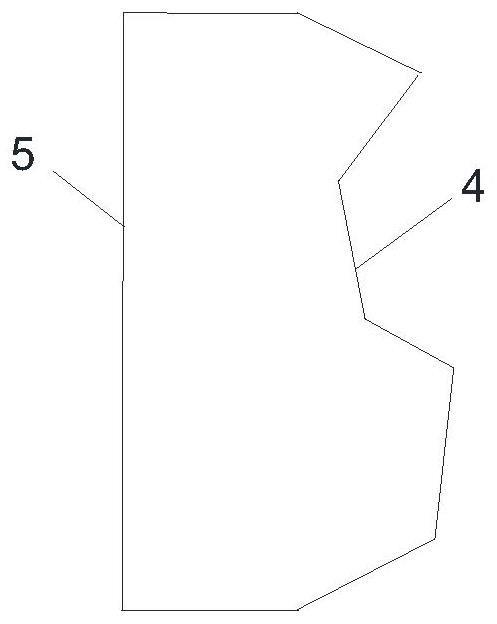

[0150] A preparation method of a product based on a connection mold for a water supply and drainage pipe head, such as Figure 5 As shown, the product for preparing the connection to the water supply and drainage pipe head 1, including

[0151] According to the preset length, the end of the water supply and drainage pipe head 1 is inserted into the cavity formed by the inner cylinder 22 and the outer cylinder 21 .

[0152] Follow the installation mold.

[0153] The mold and the water supply and drainage pipe head 1 are sleeved on the roller shaft, and the rotation of the roller shaft is started, wherein the roller shaft is a kind of rotating shaft that drives the water supply and drainage pipe pipe head 1 to rotate, which is an application that can be realized in this embodiment and does not belong to this embodiment. The scope of protection of the embodiment.

[0154] The raw material of the same material as that of the water supply and drainage pipe head 1 is injected into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com