Structural arrangement suitable for caving treatment of large goaf of underground mine

A technology for structural layout and gobs, which is applied in underground mining, surface mining, earthwork drilling, etc., can solve problems such as complex goaf treatment procedures, high cost of goaf treatment engineering, and poor safety conditions, so as to avoid construction The effects of pressure relief skylight, elimination of potential safety hazards, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

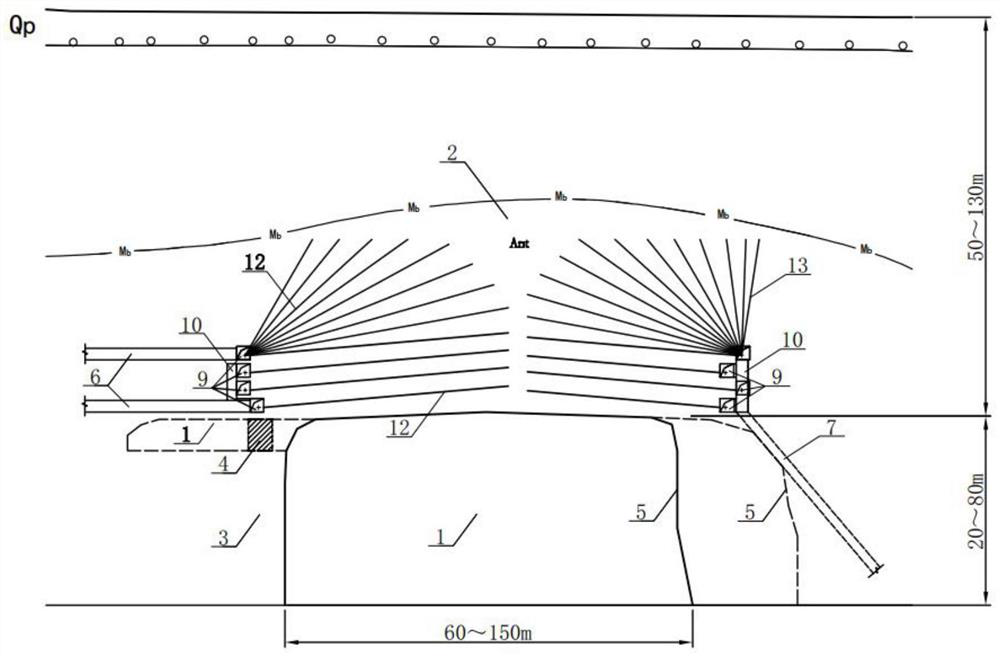

[0021] In order to better describe the present invention, a structural arrangement of the present invention suitable for the roofing treatment of a large goaf in an underground mine will be further described in detail below with reference to the accompanying drawings.

[0022] Depend on figure 1 The plan view of a structure arrangement of the present invention that is suitable for the roofing treatment of large-scale goafs in underground mines is shown in combination with figure 2 It can be seen that the present invention divides the underground mining project into four parts: gob 1, gob roof 2, gob surrounding rock 3, and irregular point columns 4. Gob 1, gob roof 2, mining The gob boundary 5 is between the surrounding rocks 3 of the gob; the downhole gob 1 divides the surrounding rock 3 of the gob 1 into 3 operating areas or explosion areas according to the results of rock mechanics calculation and analysis. Namely: work area or blast area A, work area or blast area B, wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com