Method of preparing needle-shaped second phase for improving degradation resistance of medical magnesium alloy

A magnesium alloy and needle-shaped technology, which is applied in the field of preparing the needle-shaped second phase to improve the degradation resistance of medical magnesium alloys, can solve the problems of affecting the growth and healing of damaged bones, the decline of mechanical properties, and the fast degradation speed, etc. Corrosion, good resistance to degradation, effect of improving resistance to degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 9.88 grams of AZ61 powder (particle size 50-80 μm) and 0.12 grams of rare earth element Ce powder (particle size 1-5 μm), place the two in a ball mill, and ball mill them under a protective atmosphere to obtain a uniformly mixed powder. 350 rpm, ball milling time 3 hours. Using the above mixed powder as raw material, the acicular Al-containing 4 Ce-phase medical magnesium alloy; during the preparation process, the laser power is controlled to 90W, the scanning speed is 300mm / min, and the spot diameter is 80μm.

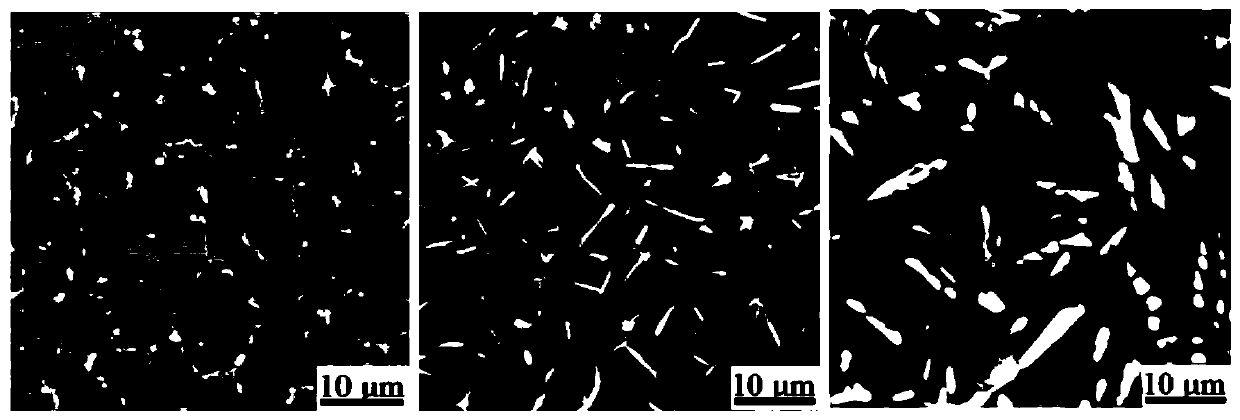

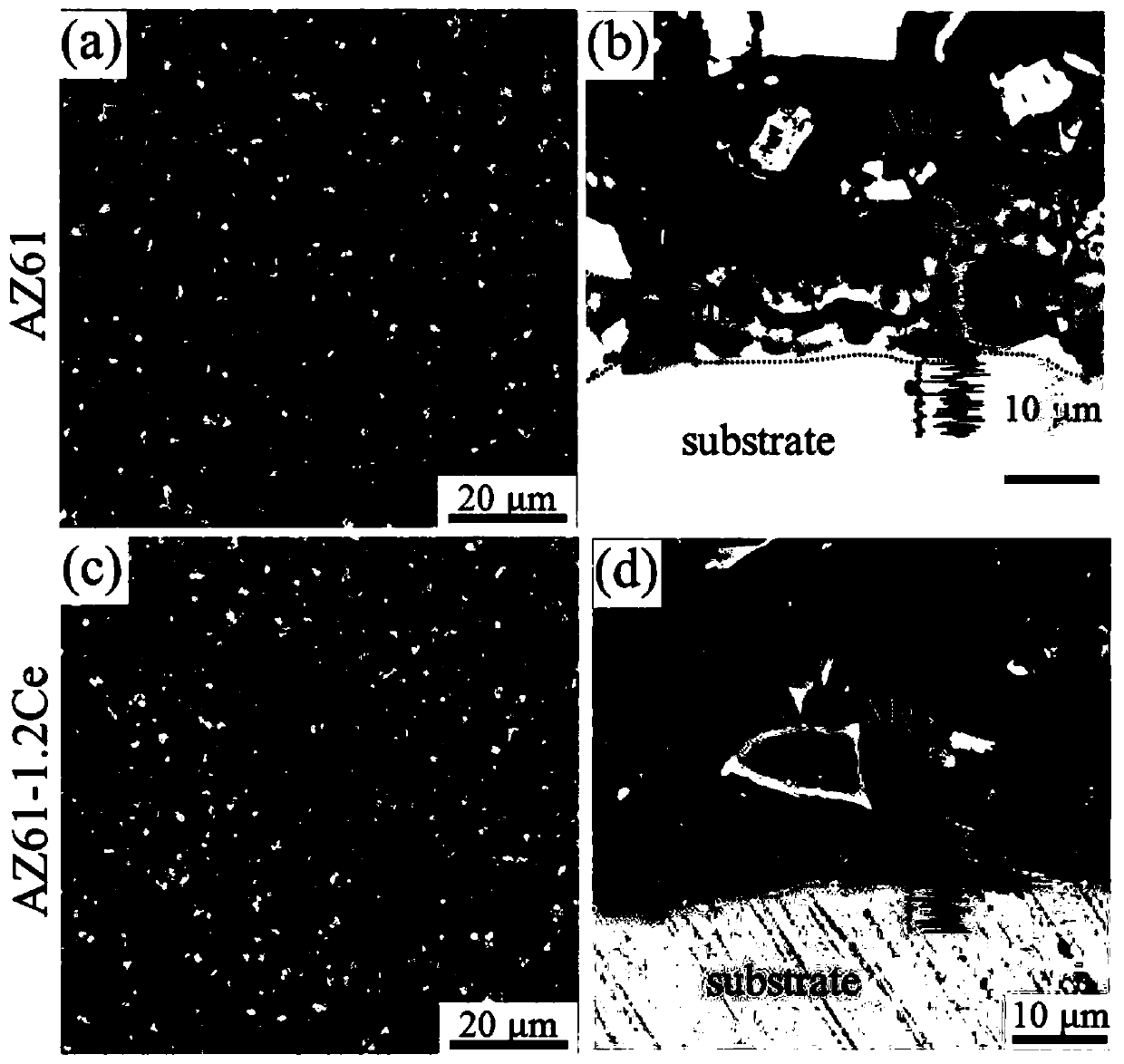

[0028] The test found that fine grains and needle-like Al were formed in the prepared alloy 4 Ce phase, Al 4 The Ce phase is distributed uniformly and dispersed inside the grains, and at the same time it refines and reduces the Mg 17 Al 12 The precipitation of the second phase ( figure 1 ). Electrochemical tests found that, compared with the AZ61 alloy, the needle-like Al 4 The corrosion current of Ce-phase magnesium alloy is 40.91μA / cm from AZ61 2...

Embodiment 2

[0030] Weigh 9.88 grams of AZ61 powder (particle size 50-80 μm) and 0.12 grams of rare earth element Ce powder (particle size 1-5 μm), place the two in a ball mill, and ball mill them under a protective atmosphere to obtain a uniformly mixed powder. 350 rpm, ball milling time 3 hours. Using the above mixed powder as raw material, the acicular Al-containing 4 Ce-phase medical magnesium alloy; during the preparation process, the laser power is controlled to 70W, the scanning speed is 300mm / min, and the spot diameter is 80μm.

[0031] The test found that fine grains and needle-like Al were formed in the prepared alloy 4 Ce phase, Al 4 The Ce phase is distributed uniformly and dispersed inside the grains, and at the same time it refines and reduces the Mg 17 Al 12 Precipitation of the second phase. Electrochemical tests found that, compared with the AZ61 alloy, the corrosion current of the magnesium alloy containing the needle-like Al4Ce phase increased from 40.91μA / cm 2 Red...

Embodiment 3

[0033] Weigh 9.76 grams of AZ61 powder (particle size 50-80 μm) and 0.24 grams of rare earth element Ce powder (particle size 1-5 μm), place the two in a ball mill, and ball mill them under a protective atmosphere to obtain a uniformly mixed powder. 350 rpm, ball milling time 3 hours. Using the above mixed powder as raw material, the acicular Al-containing 4 Ce-phase medical magnesium alloy; during the preparation process, the laser power is controlled to 90W, the scanning speed is 300mm / min, and the spot diameter is 80μm.

[0034] The test found that fine grains and needle-like Al were formed in the prepared alloy 4 Ce phase, Al 4 The Ce phase is distributed uniformly and dispersed inside the grains, and at the same time it refines and reduces the Mg 17 Al 12 Precipitation of the second phase. Electrochemical tests found that, compared with the AZ61 alloy, the needle-like Al 4 The corrosion current of Ce-phase magnesium alloy is 40.91μA / cm from AZ61 2 Reduced to 22.34μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com