Process for preparing Fenton catalyst by using KOH modified rice husks, and applications of Fenton catalyst in degradation of printing and dyeing wastewater

A catalyst and rice husk technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, oxidized water/sewage treatment, etc., can solve problems such as complex processes, and achieve low preparation costs and selectivity Strong, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

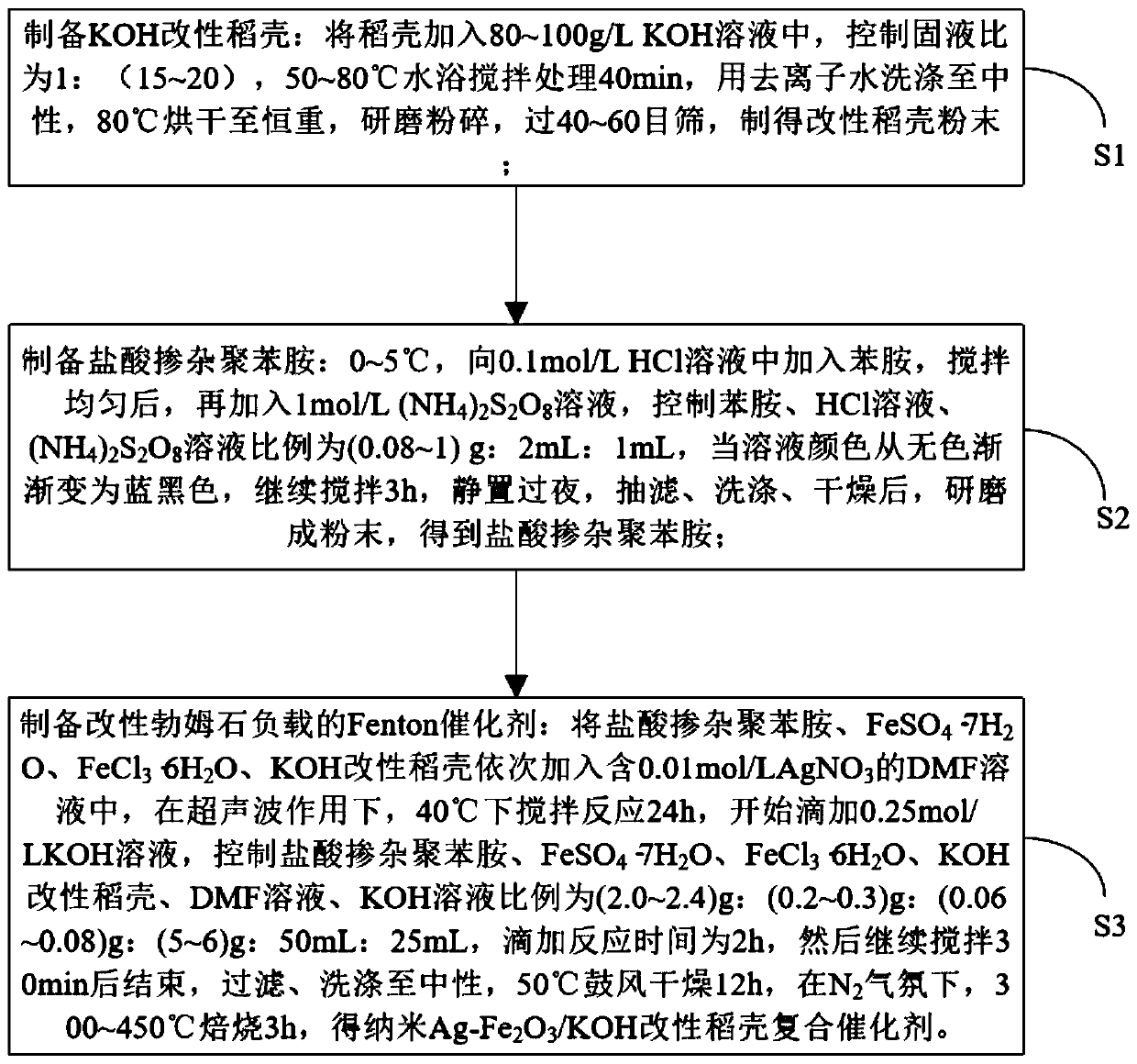

[0023] Example 1 Preparation of Fenton catalyst with KOH modified rice husk as carrier

[0024] S1: Preparation of KOH modified rice husk: Add 10 g of rice husk to 150 ml of 80 g / L KOH solution, stir in a water bath at 50 °C for 40 min, wash with deionized water until neutral, dry at 80 °C to constant weight, grind and pulverize, Pass through a 50-mesh sieve to obtain modified rice husk powder;

[0025] S2: Preparation of hydrochloric acid-doped polyaniline: at 0°C, add 6.98 g of aniline to 150 mL of 0.1 mol / L HCl solution, stir evenly, and then add 75 mL of 1 mol / L (NH 4 ) 2 S 2 O 8 The solution, when the color of the solution gradually changed from colorless to blue-black, continued to stir for 3h, left standing overnight, after suction filtration, washed three times with 0.01mol / L hydrochloric acid solution and acetone respectively, and then washed with deionized water until the pH was 6 , the filter cake was dried by blasting at 65°C and washed to constant weight, and ...

Embodiment 2

[0027] Example 2 Preparation of Fenton catalyst with KOH modified rice husk as carrier

[0028]S1: Preparation of KOH modified rice husk: add 10 g of rice husk to 150 ml of 80 g / L KOH solution, stir in a water bath at 70 °C for 40 min, wash with deionized water until neutral, dry at 80 °C to constant weight, grind and pulverize, Pass through a 50-mesh sieve to obtain modified rice husk powder;

[0029] S2: Preparation of hydrochloric acid-doped polyaniline: at 0°C, add 6.98 g of aniline to 150 mL of 0.1 mol / L HCl solution, stir evenly, and then add 75 mL of 1 mol / L (NH 4 ) 2 S 2 O 8 The solution, when the color of the solution gradually changed from colorless to blue-black, continued to stir for 3h, left standing overnight, after suction filtration, washed three times with 0.01mol / L hydrochloric acid solution and acetone respectively, and then washed with deionized water until the pH was 6 , the filter cake was dried by blasting at 65°C and washed to constant weight, and g...

Embodiment 3

[0031] Example 3 Preparation of Fenton catalyst with KOH modified rice husk as carrier

[0032] S1: Preparation of KOH-modified rice husks: Add 10 g of rice husks to 150 ml of 80 g / L KOH solution, stir in a water bath at 80 °C for 40 min, wash with deionized water until neutral, dry at 80 °C to constant weight, grind and pulverize, Pass through a 50-mesh sieve to obtain modified rice husk powder;

[0033] S2: Preparation of hydrochloric acid-doped polyaniline: at 0°C, add 6.98 g of aniline to 150 mL of 0.1 mol / L HCl solution, stir evenly, and then add 75 mL of 1 mol / L (NH 4 ) 2 S 2 O 8 The solution, when the color of the solution gradually changed from colorless to blue-black, continued to stir for 3h, left standing overnight, after suction filtration, washed three times with 0.01mol / L hydrochloric acid solution and acetone respectively, and then washed with deionized water until the pH was 6 , the filter cake was dried by blasting at 65°C and washed to constant weight, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com