High-performance primary large-particle ternary positive electrode composite material, manufacturing method and application thereof

A composite material and cathode material technology, applied in the field of new energy materials, can solve problems such as poor conductivity, low capacity, and small primary particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

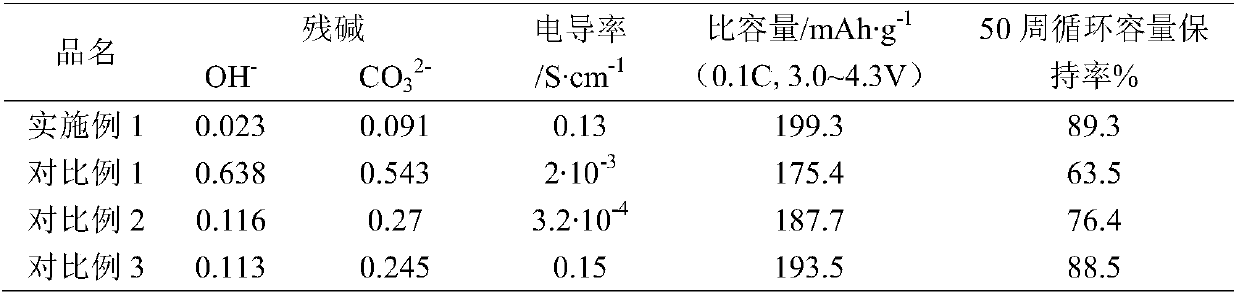

Embodiment 1

[0075] A method for preparing a primary large-grain high-nickel ternary positive electrode material, the steps of which are as follows:

[0076] (1) Weigh 100g of Ni 0.88 co 0.09 al 0.03 (OH) 2 Precursor, Ni 0.88 co 0.09 al 0.03 (OH) 2 Precursor and LiOH are mixed in a molar ratio of 1:1.03, and sintered once at 700°C for 5 hours to obtain material A;

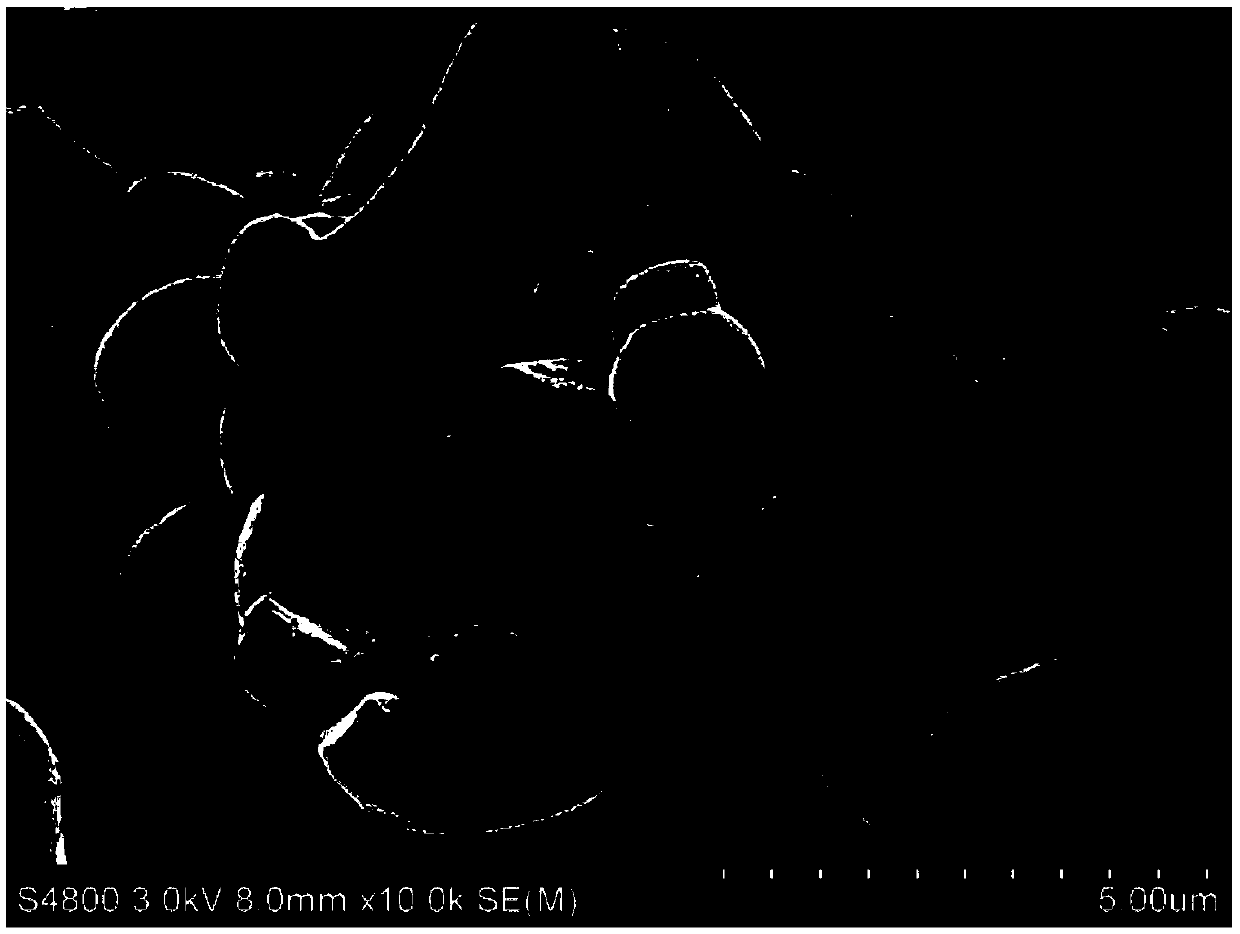

[0077] (2)Add H 3 BO 3 , so that H 3 BO 3 The addition amount of material A is 1000ppm, and wet high-energy ball milling, the dispersant is ethanol, the mixed material is ball milled to the nanometer level, and the secondary sintering is carried out at 850°C for 10 hours to obtain a primary large-particle high-nickel ternary positive electrode Material B, its primary particle size is about 5 μm;

[0078] (3) Add nano-sulfur so that the amount of nano-sulfur relative to material B is 500ppm, mix and ball mill at 200r / min for 2h and sinter and coat at 200°C to obtain material C;

[0079](4) Hydrophobic sodium alkylbe...

Embodiment 2

[0083] A method for preparing a primary large-grain high-nickel ternary positive electrode material, the steps of which are as follows:

[0084] (1) Weigh 100g of Ni 0.88 co 0.09 al 0.03 (OH) 2 Precursor, Ni 0.88 co 0.09 al 0.03 (OH) 2 Precursor and LiOH are mixed in a molar ratio of 1:1.05, and sintered once at 700°C for 5 hours to obtain material A;

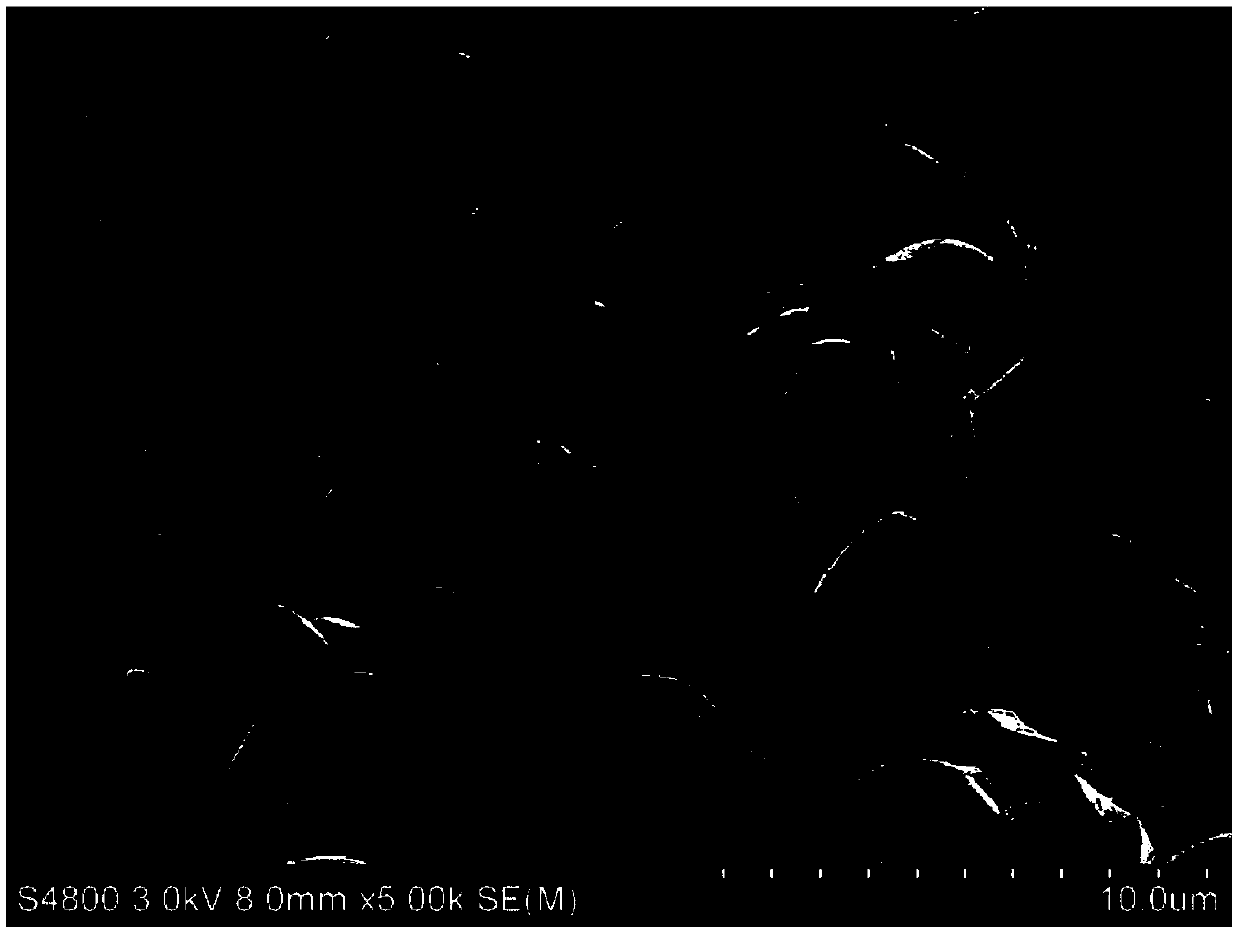

[0085] (2) Add 1500ppm of ZrO to material A 2 And wet high-energy ball milling, the dispersant is ethanol, the mixed material is ball-milled to the nanometer level, and the secondary sintering is carried out at 850 ° C for 10 hours to obtain the primary large-particle high-nickel ternary positive electrode material B, and the primary particle size is about 6 μm ;

[0086] (3) Add 1000ppm of nano-sulfur to material B, mix and ball mill it at 200r / min for 1 hour, and sinter and coat at 200°C to obtain material C;

[0087] (4) 1000ppm hydrophobic alkylbenzene sulfonate is added to the aqueous solution of PEDOT-PSS contai...

Embodiment 3

[0091] A method for preparing a primary large-grain high-nickel ternary positive electrode material, the steps of which are as follows:

[0092] (1) Weigh 200g of Ni 0.8 m 0.2 (OH) 2 Precursor, Ni 0.8 m 0.2 (OH) 2 The precursor and LiOH are mixed in a molar ratio of 1:1.12, and sintered at 750°C for 3 hours to obtain material A;

[0093] (2)Add H 3 BO 3 , so that H 3 BO 3 The amount of addition of material A is 2500ppm, and wet high-energy ball milling, the dispersant is ethanol, ball milling the mixed material to the nanometer level and performing secondary sintering at 950°C for 5 hours to obtain a primary large-particle high-nickel ternary positive electrode Material B, its primary particle size is about 7 μm;

[0094] (3) Add nano-sulfur so that the amount of nano-sulfur relative to material B is 2000ppm, mix and ball mill at 300r / min for 1h and sinter and coat at 300°C to obtain material C;

[0095] (4) Hydrophobic sodium alkylbenzene sulfonate is added to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com