Large X-ray inspection system detector structure

A technology for inspection systems and detectors, applied in air-conditioning systems, nuclear radiation exploration, instruments, etc., can solve the problems of increased processing difficulty and cost, complicated shape correction process, large welding deformation, etc., to improve maintainability, Strong environmental adaptability and the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

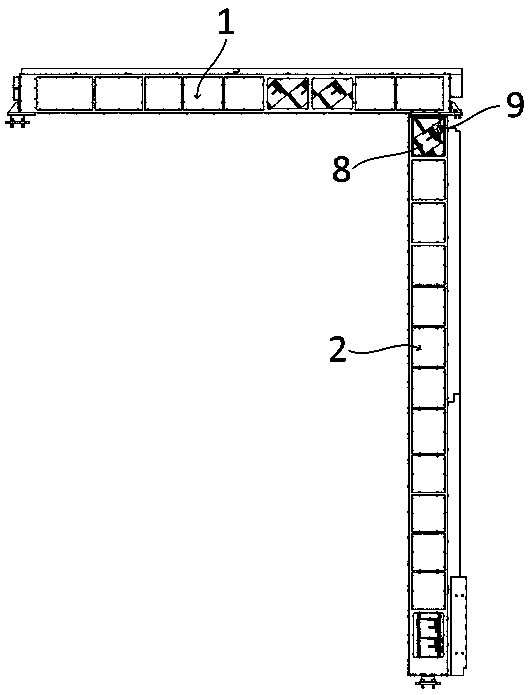

[0035] as attached Figure 1~2 As shown, a detector structure of a large-scale X-ray inspection system consists of three parts: basic components, detection components and heat dissipation / heating components.

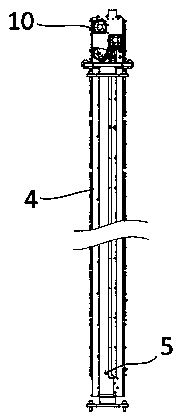

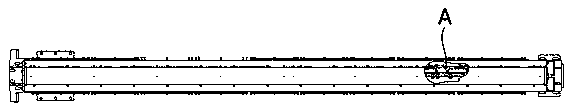

[0036] Wherein, the basic components include: a detection arm, a cover plate 4 , an air inlet channel 6 and an air outlet channel 7 . Wherein, the detection arm is vertically connected together by two mutually perpendicular horizontal arms 1 and vertical arms 2 through screws or bolts, and its side shape is "L". The structure of the cross arm 1 and the vertical arm 2 is the same, more specifically, the cross arm 1 includes: a cross beam 3 made of aluminum alloy or steel I-beam, and a plurality of cover plates sealed and installed on the outside of the cross beam 3 4, and the lead baffle 5 arranged on the outside of the cover plate 4. have to be aware of is, figure 1 , in order to show the internal structure of the detection arm, in the attached figure 1 There are som...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com