Building waste crushing and screening device and method

A technology for crushing, screening, and construction waste, applied in the fields of construction-related equipment and solid waste recycling, can solve problems such as poor results, ineffective use of mixtures, and low production efficiency, to avoid environmental pollution effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

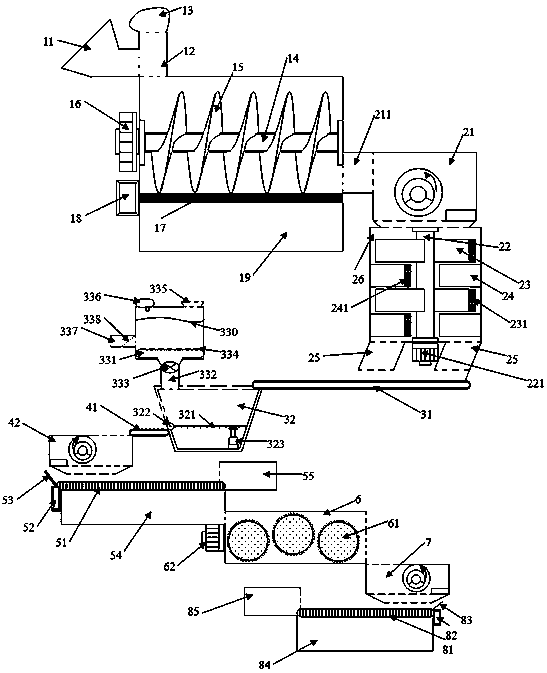

[0050] Further explanation with the attached drawings: such as Figure 1 to Figure 3 The construction waste crushing and screening device shown includes a primary crushing screening component, a fine crushing screening component and a grinding screening component.

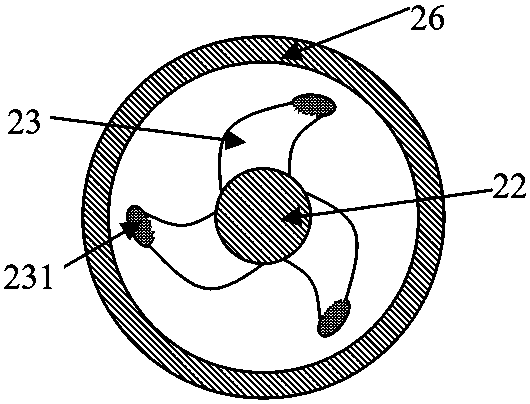

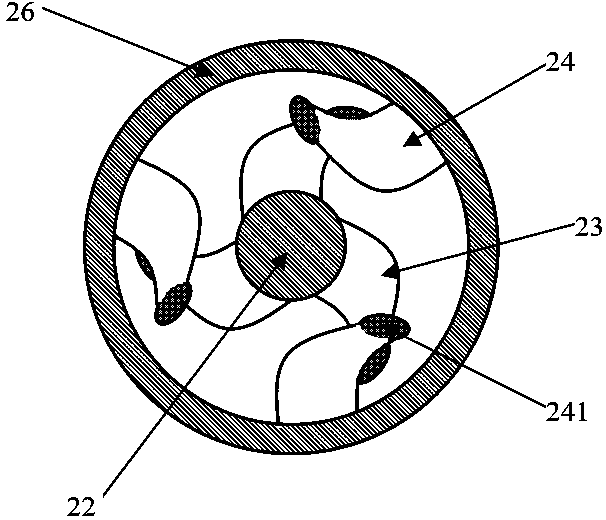

[0051] Such as figure 1 As shown, the primary crushing screening components include the main garbage inlet 11, the inlet vertical pipe 12, the ash retaining sac 13, the outer wall of the primary crushing cavity, the primary crushing cavity inlet (the lower part of the inlet vertical pipe), the primary crushing shaft 14, and the primary The breaking blade 15, the initial breaking motor 16, the initial breaking cavity outlet (the lower right of the initial breaking shaft), the first vibrating screen 17, the first vibration generator 18 and the original soil collection box 19; the outer wall of the initial breaking cavity is as a whole In a horizontal cylindrical structure, the initial breaking cavity inlet is set at the...

Embodiment 2

[0066] A method for crushing and screening construction waste, using the construction waste crushing and screening device of Example 1, specifically including the following steps:

[0067] (1) Drain the construction waste into the outer wall of the primary crushing cavity through the main entrance of the waste, start the primary crushing motor, and use the primary crushing blades to perform primary crushing of the materials entering the primary crushing cavity. The soil during the crushing process passes through the primary crushing cavity. A vibrating screen falls into the original soil collection box, mainly the original soil less than 25mm, because the primary crushing can peel off most of the original soil, and the original soil basically has no negative effect on the environment, so the original soil can be directly After being dumped to wasteland for fertilizer, it can be used as ordinary land. Therefore, after the original soil collection box is full, the soil material is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com