Lubricating and cooling structure for high-power durability test of gear

A durability test, lubrication and cooling technology, applied in the direction of gear lubrication/cooling, gear transmission, belt/chain/gear, etc., can solve the problems of reducer temperature rise, large load, cost increase, etc., to improve cooling and lubrication effect, reduce abnormal rise, and ensure smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

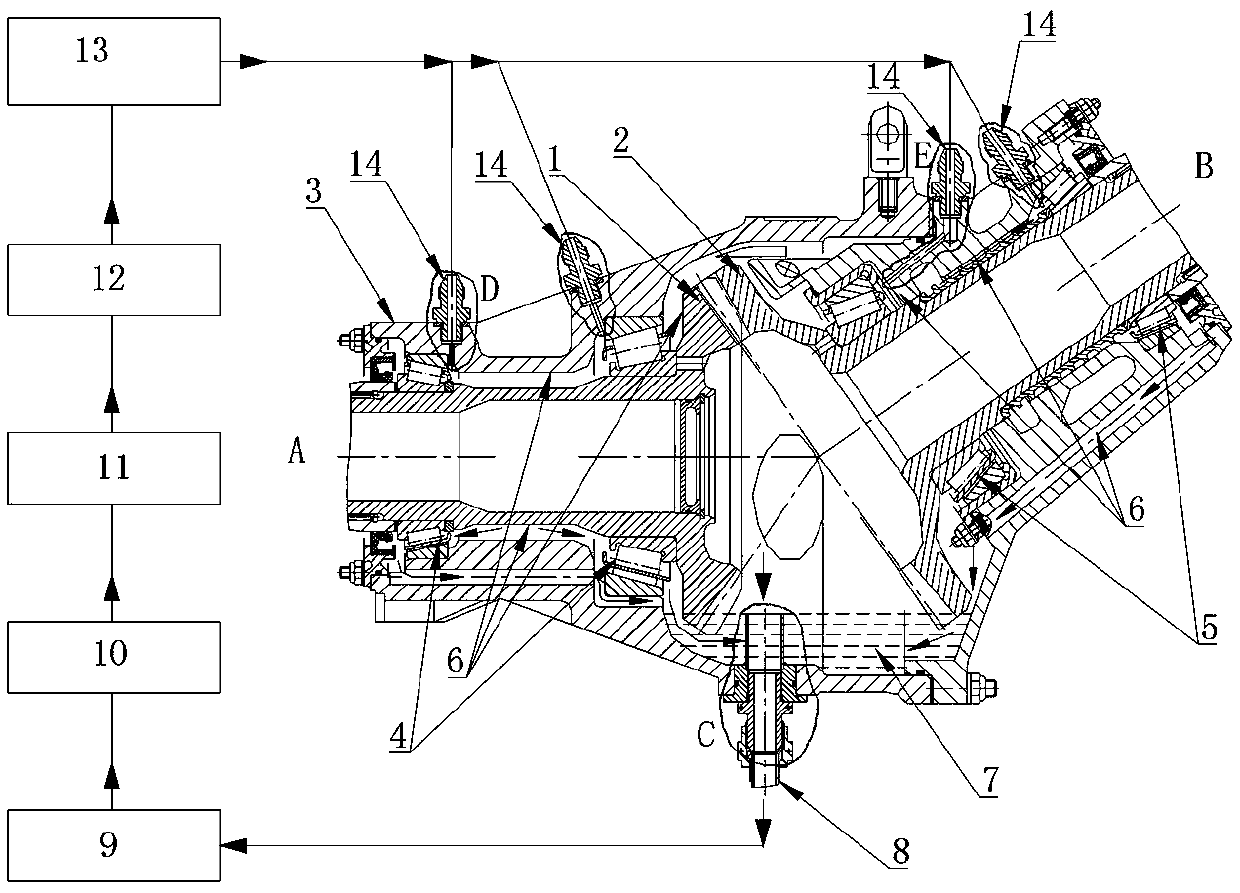

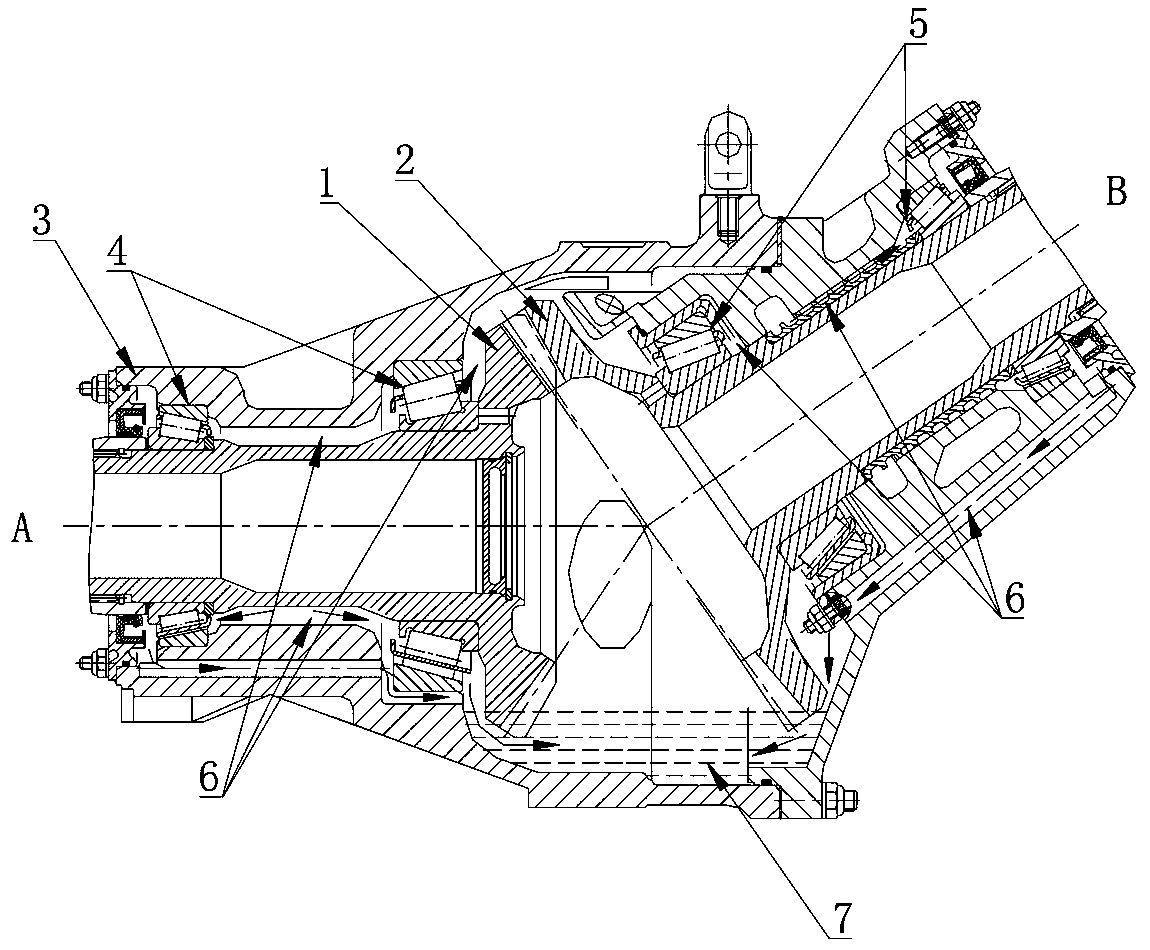

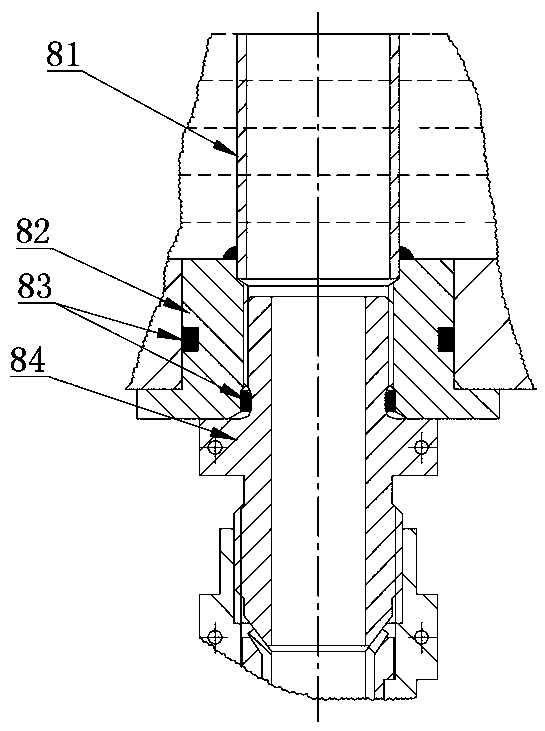

[0031] Such as Figure 1 to 6 As shown, a lubricating and cooling structure used for gear high-power durability test includes driving wheel 1, driven wheel 2, casing 3, first bearing group 4, second bearing group 5, oil circuit 6 and oil storage area 7. The driving wheel 1 and the driven wheel 2 are engaged for transmission. The gear shafts of the driving wheel 1 and the driven wheel 2 are installed in the receiver 3 through the first bearing set 4 and the second bearing set 5, respectively. The driving wheel 1 and the driven wheel 2 are both There is an oil circuit 6 between the casing 3 and the oil storage area 7 at the bottom of the casing 3. The lubricating oil splashes to the oil circuit 6 and reaches the oil storage area 7 under the action of gravity. The lubrication and cooling structure also includes an oil pump 9 connected in sequence , Radiator 10, oil storage tank 11, delivery pump 12 and spray lubrication device 14, the oil pump 9 is connected with the oil storage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com