Integrated internal circulation spheroidizing machine

An internal circulation and integrated technology, applied in the direction of fertilizer form, mold extrusion granulation, fertilizer mixture, etc., can solve the problems of small movement speed difference, low round throwing efficiency, waste generation, etc., to save space and prolong The effect of throwing time and guaranteeing roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

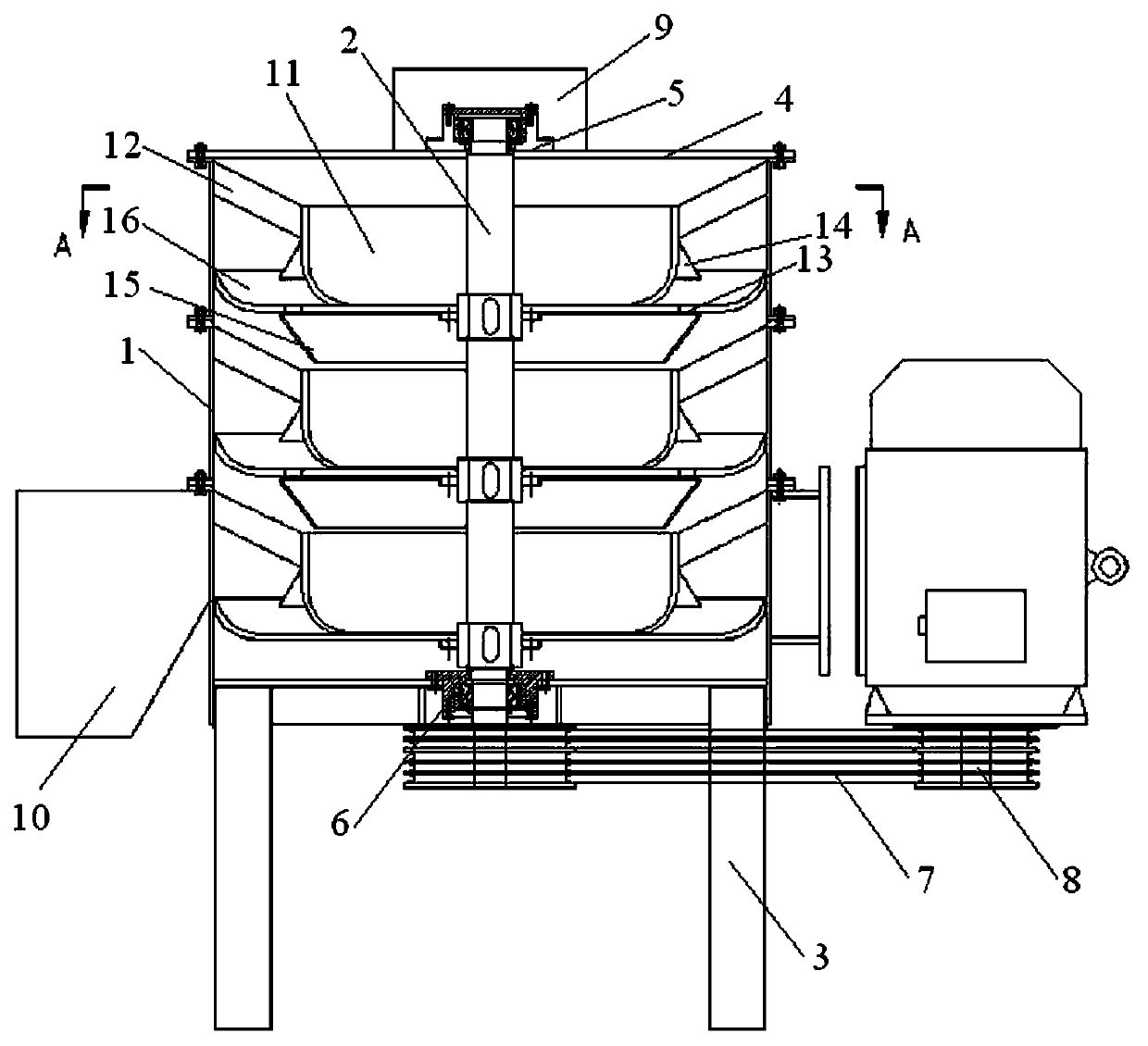

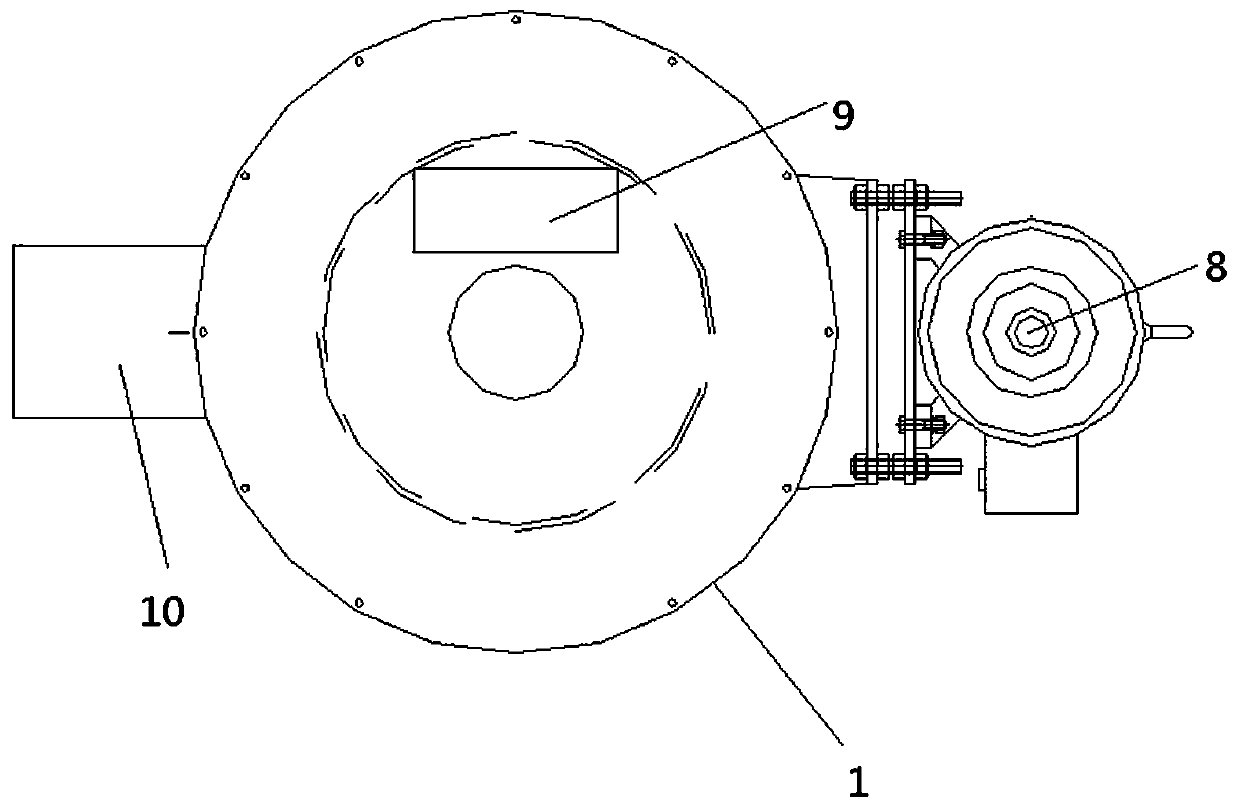

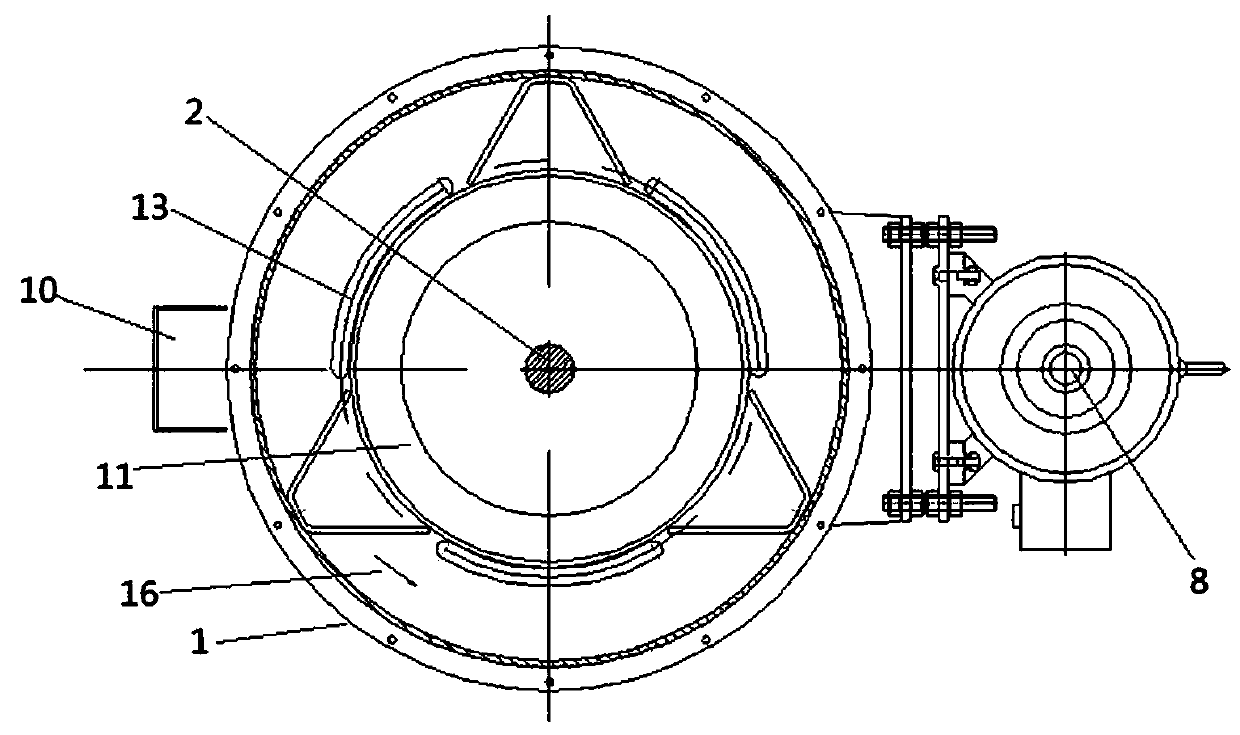

[0026] Integrated internal circulation round polishing machine, such as Figure 1-6 As shown, it includes an outer cylinder 1, the central axis of the outer cylinder 1 is provided with a rotating shaft 2, the outer cylinder 1 is fixedly supported by legs 3, and the upper end of the outer cylinder 1 is fixed with an upper cover plate 4. The center of the upper cover plate 4 is provided with an upper bearing 5, the center of the bottom of the outer cylinder 1 is provided with a lower bearing 6, and the two ends of the rotating shaft 2 are respectively connected with the upper bearing 5 and the lower bearing 6 with an interference fit. One end of the rotating shaft 2 runs through the bearing, and is linked with the motor drive shaft 8 through the conveyor belt 7. The upper cover plate 4 is also provided with a feed port 9, and the lower part of the outer cylinder 1 is provided with a discharge port 10. Several layers of throwing disks are fixed at equal intervals on the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com