Intermediate connection system for ultra-high-voltage direct current power cable

A power cable and connection system technology, applied in the field of intermediate connection systems, can solve problems such as electric field distortion, dielectric breakdown, and electric field distortion of insulating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

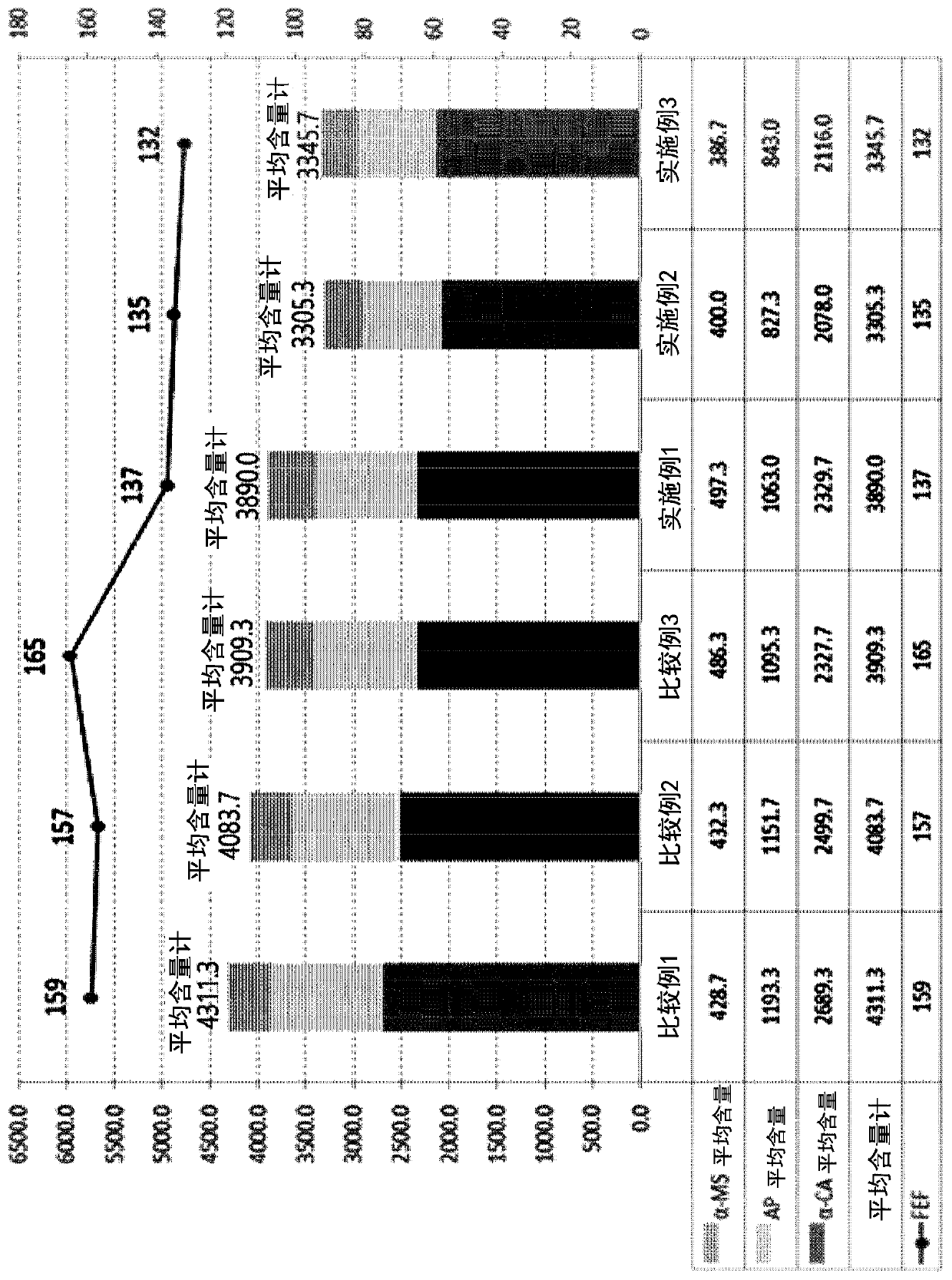

[0098] Cable insulation samples were manufactured separately, the thickness of the cable insulation samples was about 120 μm, after cross-linking according to the content of cross-linking agent and the adjustment of degassing time, the various cross-linking by-products of each layer / cross-linking by-product The content of the product was adjusted as shown in Table 1 below.

[0099] [Table 1]

[0100]

[0101] 2. Manufacturing example of insulating layer sample of intermediate connection part

[0102] Each layer / cross-linked by-product of each layer / cross-linked by-products was manufactured separately after cross-linking according to the content of the cross-linking agent and the adjustment of the degassing time. The contents of various cross-linked by-products were adjusted as shown in Table 2 below.

[0103] [Table 2]

[0104]

[0105] 2. Evaluation of physical properties

[0106] 1) Determination of the electric field enhancement factor (FEF) of the cable insulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com