Ultra-high voltage direct current power cable

A power cable, ultra-high voltage technology, applied in the field of ultra-high voltage DC power cables, can solve the problems of electric field distortion, dielectric breakdown, space charge accumulation, cable insulation layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

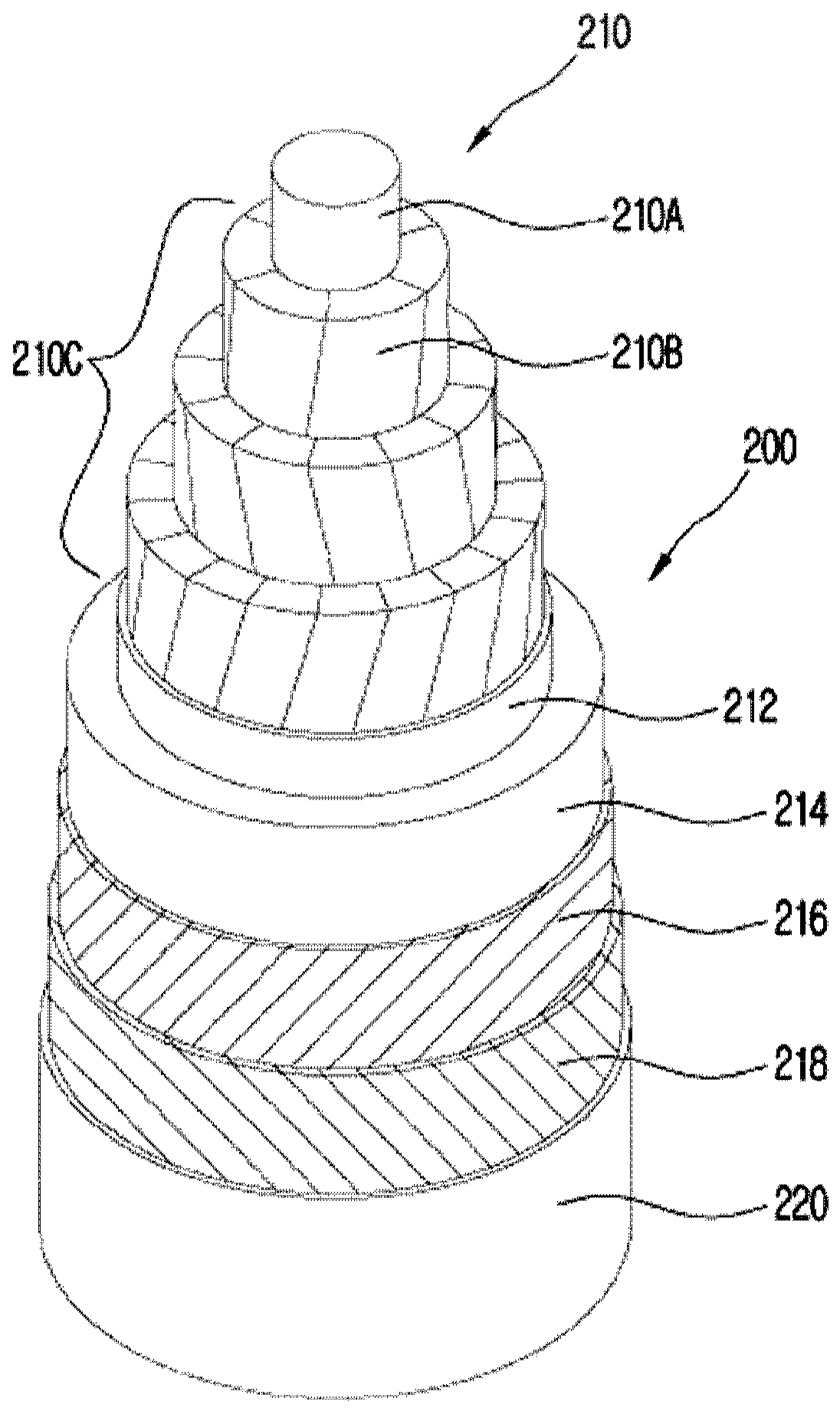

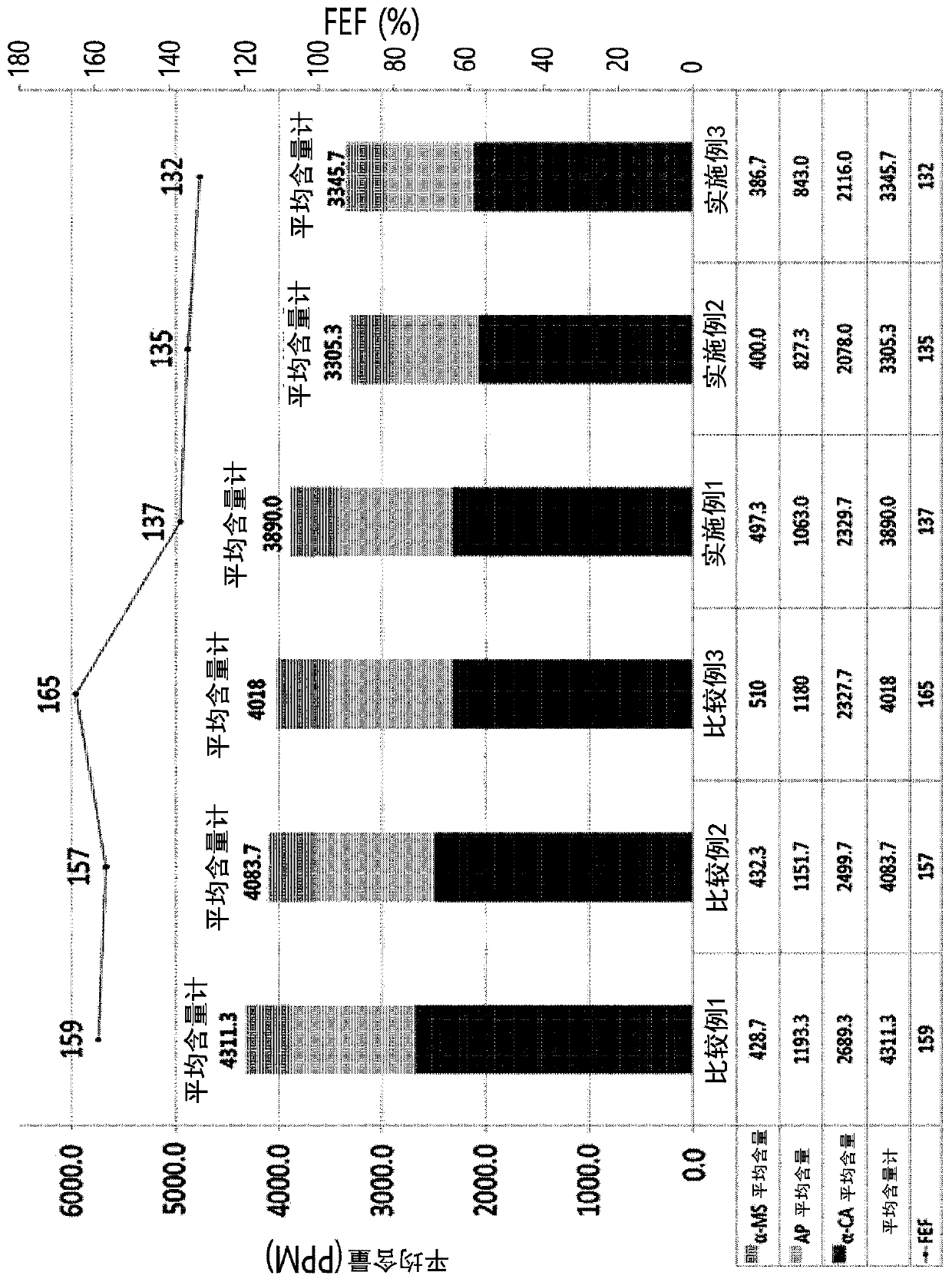

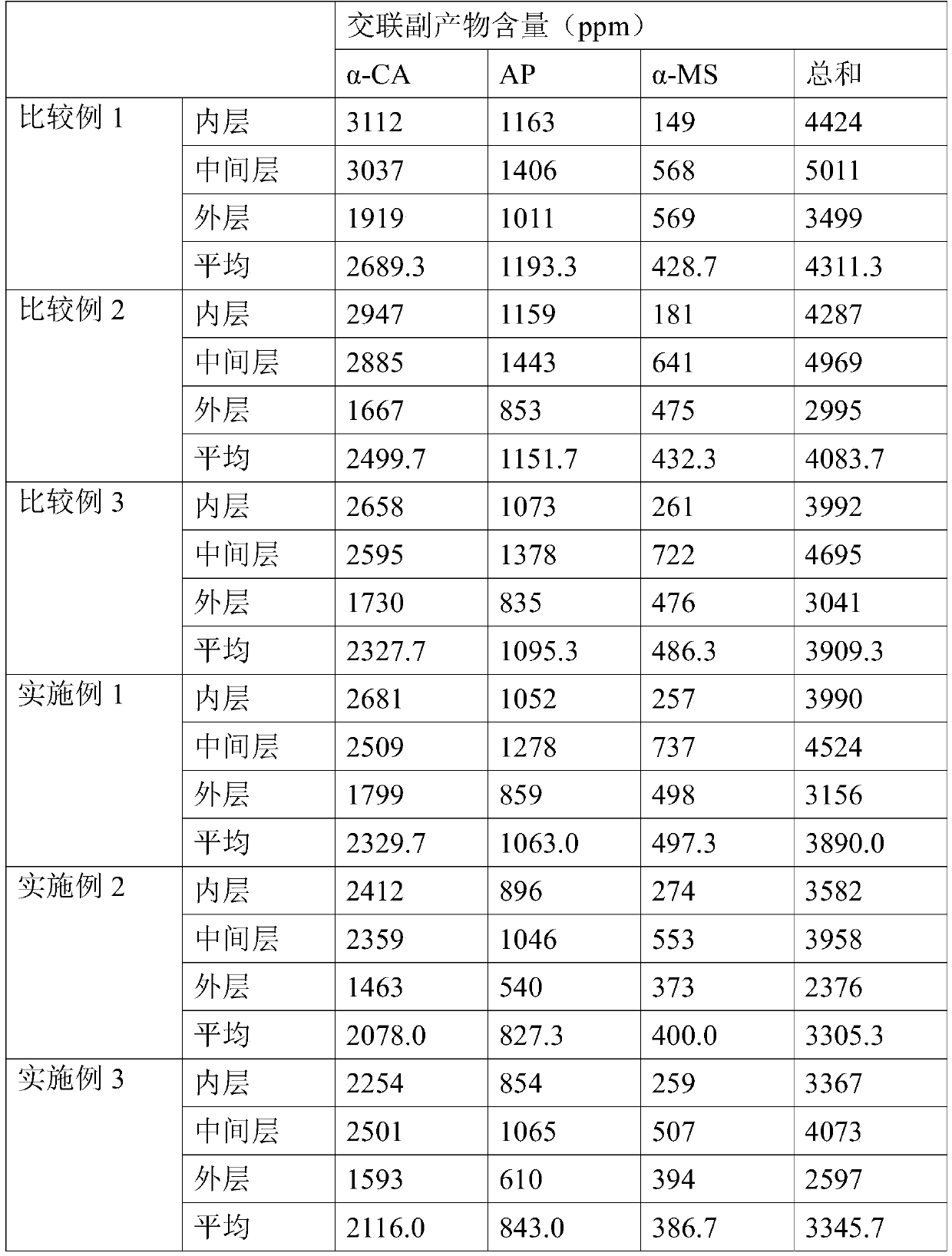

[0073] As a model cable comprising an inner semiconductive layer, an insulating layer, and an outer semiconductive layer, an insulation thickness of about 4mm, and a conductor cross-sectional area of about 400SQ, the model cables of the examples and the comparative examples were manufactured respectively, and the examples and comparative examples The model cable adjusts the content of the cross-linking agent added to the insulating layer, and adjusts the content of the cross-linking by-products through cross-linking and degassing, thereby adjusting the thickness of the insulating layer to three as shown in Table 1 below. Contents of each crosslinked byproduct of each layer / crosslinked byproduct of the inner layer, middle layer, and outer layer divided into equal parts. The content of the cross-linked by-products is measured by collecting a sample at any part in the middle of each layer.

[0074] [Table 1]

[0075]

[0076] 2. Determination of the electric field enhanceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Insulation thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com