High-performance swept-frequency fiber laser

A fiber laser, high-performance technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of frequency sweep speed dependence, slow frequency sweep speed, long delay line loss, etc., and achieve instantaneous line width narrowing , Sweeping speed increased, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

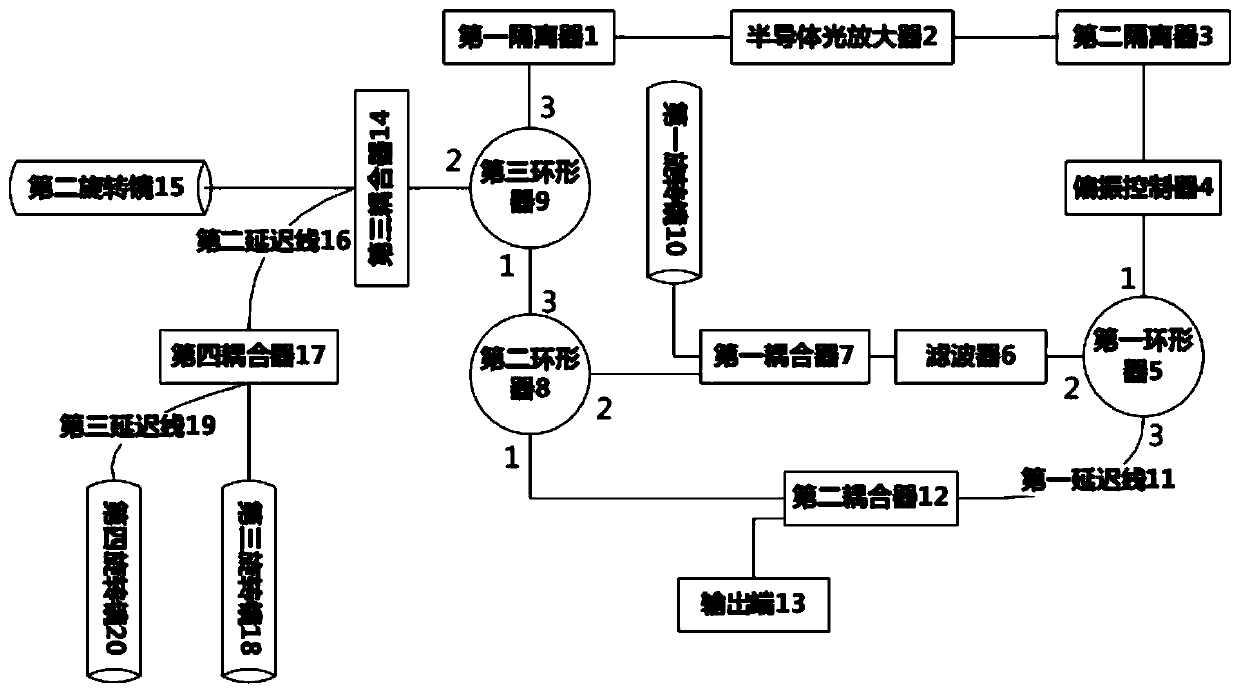

[0023] When the optical signal is output through the third pin of the first circulator 5, in order to achieve a better frequency sweeping effect, the optical signal can be further filtered, and the first delay can be connected to the third pin of the first circulator 5. Line 11 and second coupler 12.

[0024] Specifically, the first leg of the first delay line 11 described above is connected to the third leg of the first circulator 5, the second leg of the first delay line 11 is connected to the first leg of the second coupler 12, and the second coupling The second pin of the device 12 is connected to the first pin of the second circulator 8 to form a second path of the optical signal. That is, the twice-filtered optical signal output by the third pin of the first circulator 5 passes through the first delay line 11, the second coupler 12, the first pin of the second circulator 8, and the second pin of the second circulator 8. Feet, the first coupler 7, the filter 6, and the seco...

Embodiment 2

[0026] In order to further increase the frequency sweep speed of the optical signal and improve the performance of the frequency sweep laser, a frequency sweep doubling component can be installed on the above-mentioned optical path.

[0027] Specifically, the frequency sweep doubling component described above includes a third coupler 14, a second rotating mirror 15, a second delay line 16 and a third rotating mirror 18. The first leg of the third coupler 14 is connected to the second leg of the third circulator 9, the second leg of the third coupler 9 is connected to the second rotating mirror 15, and the second leg of the third coupler 14 is connected to the second delay line The first pin of 16 and the second pin of the second delay line 16 are connected to the third rotating mirror 18. It can be seen from the above that the optical signal can enter the third coupler 14 through the second leg of the third circulator 9, enter the second rotating mirror 15 through the second leg ...

Embodiment 3

[0030] In actual work, in order to ensure that the high-performance swept fiber laser described above can work stably for a long time and prevent the laser from being interrupted due to the influence of external temperature or current, the high-performance swept laser can be placed in a temperature and current controllable Environment.

[0031] Specifically, the semiconductor optical amplifier 2 in the above-mentioned high-performance swept laser is connected to a constant current drive circuit and a temperature control circuit. In order to ensure that the semiconductor optical amplifier 2 continuously and stably output the spontaneous radiation background light under the constant temperature state, the laser output will not be interrupted due to the long running time and high temperature. The constant current drive circuit and the temperature control circuit are disclosed in the Chinese patent application number 201821765806.X and the utility model patent titled "a laser light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com