Three-dimensional porous carbon-manganese oxide core shell structure material as well as preparation method and application thereof

A core-shell structure, three-dimensional porous technology, applied in the preparation/purification of carbon, manganese oxide/hydroxide, nanotechnology for materials and surface science, etc. , poor cycle stability, etc., to achieve excellent charge-discharge cycle stability, large specific surface area, and good mechanical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

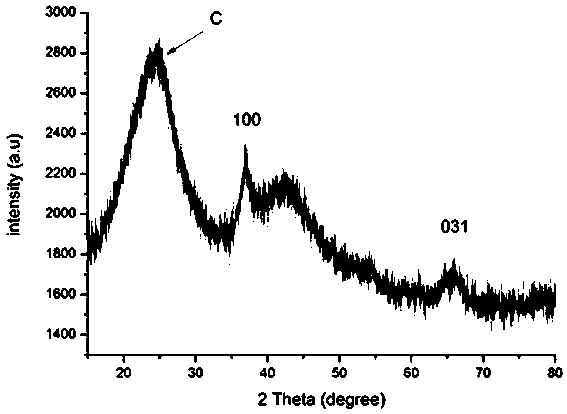

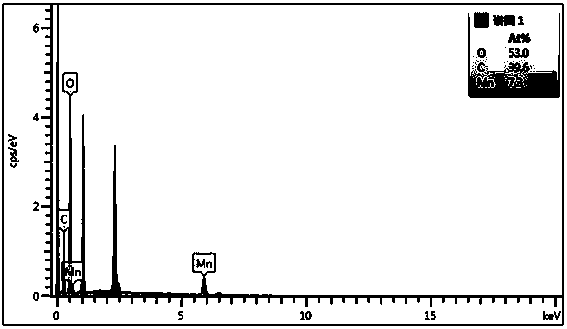

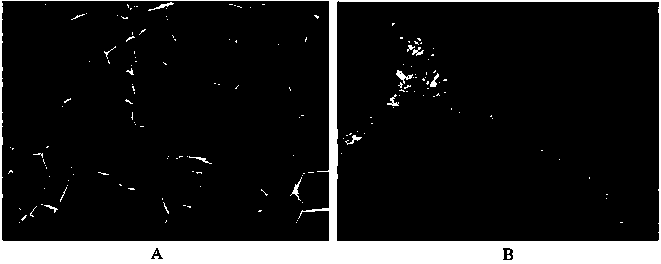

[0025] Three-dimensional porous carbon-manganese oxide core-shell materials (C@MnO 2 Nanoneedle) preparation:

[0026] 1) Preparation of three-dimensional honeycomb porous carbon skeleton: Cut the cleaned cork bark into a square shape of 10mm x 10mm x 3mm in length, dry it at 60°C and soak it in 0.5mol / L potassium hydroxide solution for 6 h, then take it out, and put it in a vacuum box to dry at 60°C for 24 h; put the treated cork bark into a ceramic boat with a cover, and then put the ceramic boat in a high-temperature horizontal tube furnace, and wait for the tube furnace When the medium vacuum degree reaches 0.1 Pa, feed high-purity Ar gas (purity up to 99.999%) at 300 mL / min, turn on the heating power, control the heating rate at 1 °C / min, heat the furnace temperature to 900 °C, and hold for 1.5 h, and then cooled to room temperature with the furnace under the protection of Ar gas, a three-dimensional honeycomb porous carbon framework with regular arrangement was obtained...

Embodiment 2

[0036] Three-dimensional porous carbon-manganese oxide core-shell materials (C@MnO 2 Nanoflowers) preparation:

[0037] 1) Preparation of three-dimensional honeycomb porous carbon skeleton: cut the cleaned cork bark into a square shape of 10 mm x 10 mm x 3 mm in height, dry it at 60 °C and soak it in 0.7 mol / L potassium hydroxide solution for 5 h, then take it out, put it in a vacuum box and dry it at 60°C for 24 h; put the treated cork bark into a ceramic boat with a cover, then put the ceramic boat in a high-temperature horizontal tube furnace, and wait for it to When the vacuum degree reaches 0.1 Pa, feed high-purity Ar gas (purity up to 99.999%) at 300 mL / min, turn on the heating power, control the heating rate at 1 °C / min, heat the furnace to 1000 °C, and keep it for 1 h , and then cooled to room temperature with the furnace under the protection of Ar gas, a three-dimensional honeycomb porous carbon framework with regular arrangement was obtained, and its specific surfac...

Embodiment 3

[0040] Three-dimensional porous carbon-manganese oxide core-shell materials (C@MnO 2 Nanoparticles) Preparation:

[0041] 1) Preparation of three-dimensional honeycomb porous carbon skeleton: cut the cleaned cork bark into a square shape of 10mm x 10mm x 3mm in length, dry it at 60°C and soak it in 0.8mol / L potassium hydroxide solution for 4 h, then take it out, put it in a vacuum box and dry it at 60°C for 24 h; put the treated cork bark into a ceramic boat with a cover, then put the ceramic boat in a high-temperature horizontal tube furnace, and wait for it to When the vacuum degree reaches 0.1 Pa, high-purity Ar gas (purity up to 99.999%) is introduced at 300 mL / min, the heating power is turned on, the heating rate is controlled at 1 °C / min, the furnace temperature is heated to 900 °C, and the temperature is kept for 2 h , and then cooled to room temperature with the furnace under the protection of Ar gas, a three-dimensional honeycomb porous carbon framework with regular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com