Polypyrrole-phosphorus molybdenum oxide supercapacitor material and preparation method thereof

A supercapacitor and polypyrrole technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of poor rate performance and cycle stability of supercapacitors, unstable electrochemical properties of the matrix, poor electrical conductivity of supercapacitors, etc. problems, to achieve the effect of increasing double layer capacitance and pseudocapacitance, improving cycle stability and service life, and improving electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

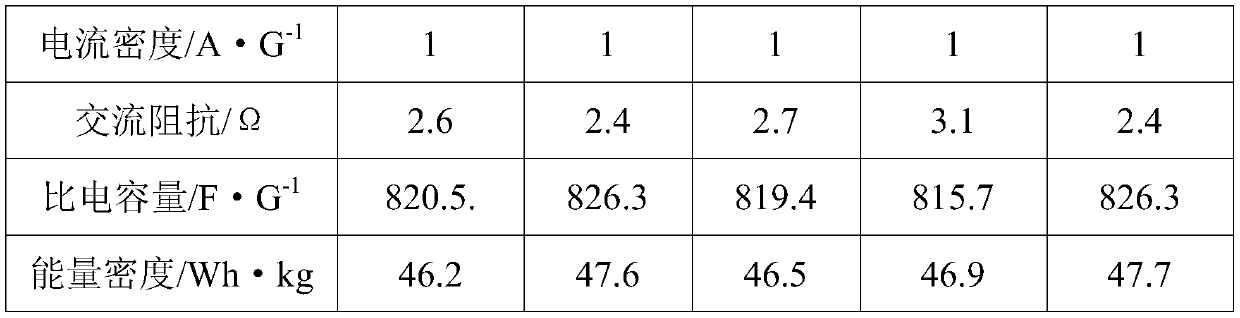

Examples

preparation example Construction

[0024] A preparation method of polypyrrole-phosphorus molybdenum oxide supercapacitor material comprises the following steps:

[0025] (1) Preparation of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo 12 o 40 -MOFs material: add 200-500mL of distilled water and 35-40 parts of phosphomolybdic acid to the hydrothermal automatic reaction kettle and stir evenly until the solid is dissolved, then add 400-800mL of ethylene glycol and 17-20 parts of 1,3,6,8 -Tetrakis(4-carboxyphenyl)pyrene, heat the temperature of the reactor to 140-150°C, stir the reaction at a constant speed for 5-8h, cool the material to room temperature after the reaction, remove the solvent by filtration to obtain a solid product, and use an appropriate amount of distilled water to dry Wash with water and ethanol to completely remove reaction impurities, and place in a blast drying oven and heat to 55-65°C to dry to obtain 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo 12 o 40 -MOFs materials.

...

Embodiment 1

[0029] (1) Preparation of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo 12 o 40 -MOFs material: Add 200mL of distilled water and 35 parts of phosphomolybdic acid to the hydrothermal automatic reaction kettle and stir evenly until the solid is dissolved, then add 400mL of ethylene glycol and 17 parts of 1,3,6,8-tetrakis(4-carboxybenzene) Pyrene, the temperature of the reactor was heated to 140°C, and the reaction was stirred at a constant speed for 5 hours. After the reaction, the material was cooled to room temperature, and the solvent was removed by filtration to obtain a solid product. Heated to 55°C in an air drying oven to obtain 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo 12 o 40 -MOFs material component 1.

[0030] (2) Preparation of Co-P 3 MoO 6 -C Composite material: Weigh 22 parts of cobalt nitrate hexahydrate and 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo prepared in the above step (1) 12 o 40 -MOFs material component 1 was added to a...

Embodiment 2

[0033] (1) Preparation of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo 12 o 40 -MOFs material: Add 300mL of distilled water and 36 parts of phosphomolybdic acid to the hydrothermal automatic reaction kettle and stir evenly until the solid is dissolved, then add 600mL of ethylene glycol and 18 parts of 1,3,6,8-tetrakis(4-carboxybenzene) Pyrene, the temperature of the reactor was heated to 140°C, and the reaction was stirred at a constant speed for 5 hours. After the reaction, the material was cooled to room temperature, and the solvent was removed by filtration to obtain a solid product. Heated to 55°C in an air drying oven to obtain 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo 12 o 40 -MOFs material component 2.

[0034] (2) Preparation of Co-P 3 MoO 6 -C Composite material: Weigh 23 parts of cobalt nitrate hexahydrate and 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene modified PMo prepared in the above step (1) 12 o 40 -MOFs material component 2 was added to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com