Olfactory sensing detection method for flour storage quality

A detection method, flour technology, applied to measuring devices, material analysis through observation of the influence of chemical indicators, instruments, etc., can solve the problems of rapid detection that have not been reported, to maintain market order, eliminate subjective interference, The effect of optimizing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

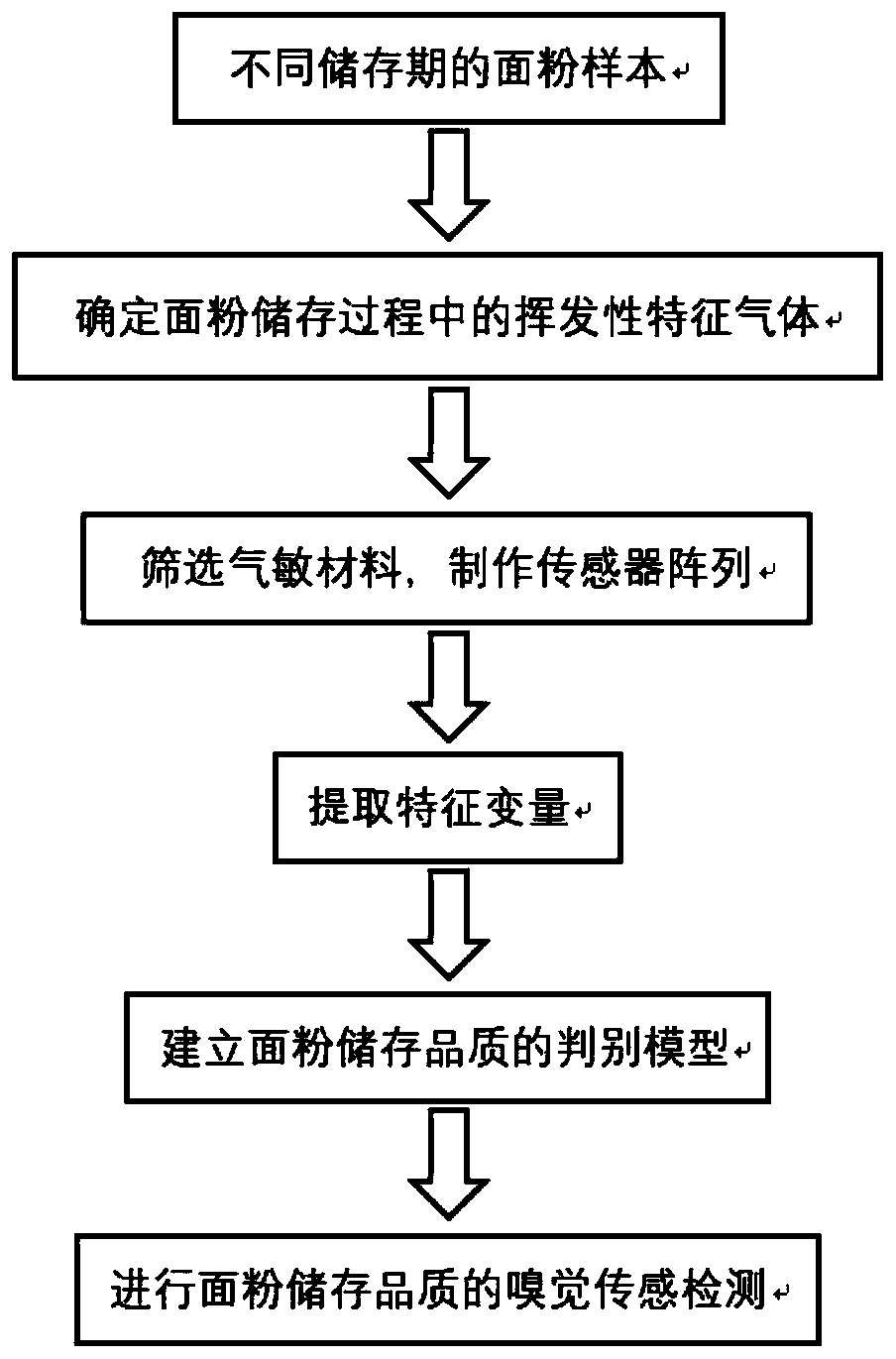

[0033] The flowchart of this method is as figure 1 As shown, the detailed description of each step is as follows:

[0034] Step 1: First, carry out GC-MS experiment, combining with the related physical and chemical indicators of flour, to determine the volatile characteristic gas during flour storage:

[0035] (1.1) Put 4g of flour sample into the extraction flask, heat it in a water bath at 80℃ for 10min, and absorb the headspace of the extraction head for 40min. After the extraction is completed, put the extraction head in the GC-MS injection port and analyze at 250℃ for 5min to complete the injection ; Among them, the chromatographic conditions are: the carrier gas He flow rate is 1.0mL / min, splitless, the inlet temperature is 230 degrees Celsius; the column temperature program is: the initial temperature is 65 degrees Celsius for 5 minutes, and the temperature rises to 100 degrees Celsius at 5 degrees Celsius / min , Raise temperature at 10℃ / min to 180℃, at 10℃ / min to 220℃, hold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com