Test device for planar three-dimensional shape based on multiple-beam angle adaptive optics and processing method thereof

A technology of adaptive optics and three-dimensional shape, applied in the field of optical inspection, can solve the problems of difficult production environment of aspheric workpieces, influence of measurement results, small measurement scale range, etc., and achieve the effect of easy implementation, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

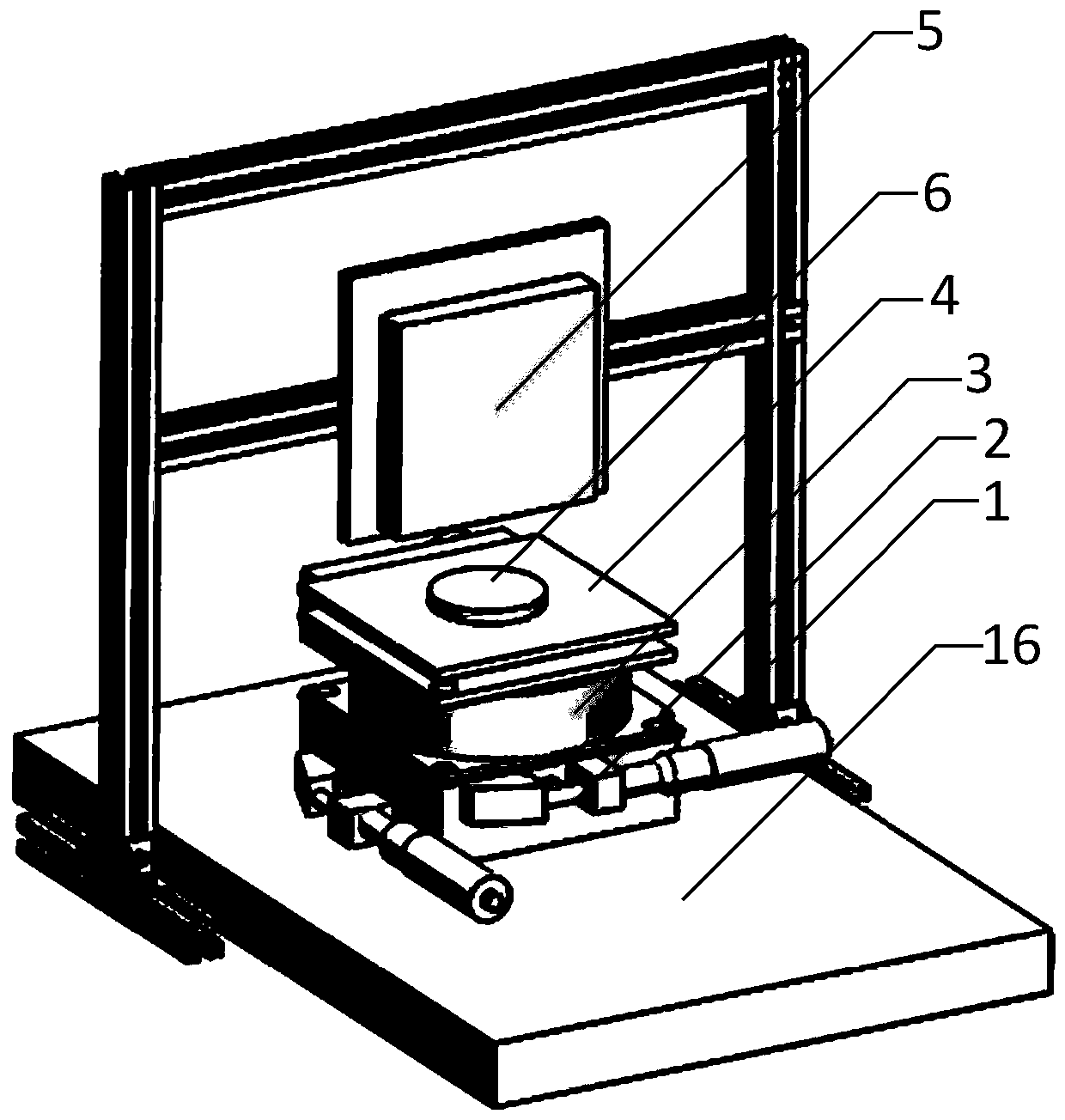

[0049] Such as figure 1 and figure 2 As shown, this embodiment discloses a flatness three-dimensional shape detection device based on complex beam angle adaptive optics, which mainly includes a bearing platform 16, a bracket 1, an XY platform 2, a rotating platform 3, a tilting platform 4, and a complex beam Angle sensor 5.

[0050] Specifically, the bearing platform 16 is horizontally and fixedly arranged. Both ends of the bracket 1 are clamped on both sides of the bearing platform 16 and are fixedly connected with the bearing platform 16 . The XY platform 2 is installed on the bearing platform 16 and is fixedly connected with the bearing platform 16 . The rotary table 3 is installed on the XY platform 2, and its position is adjusted by the XY platform 2. The tilting table 4 is arranged on the rotating table 3 , is fixedly connected with the rotating end of the rotating table 3 , and is driven to rotate by the rotating table 3 . A workpiece 6 is set on the tilt table 4 ...

Embodiment 2

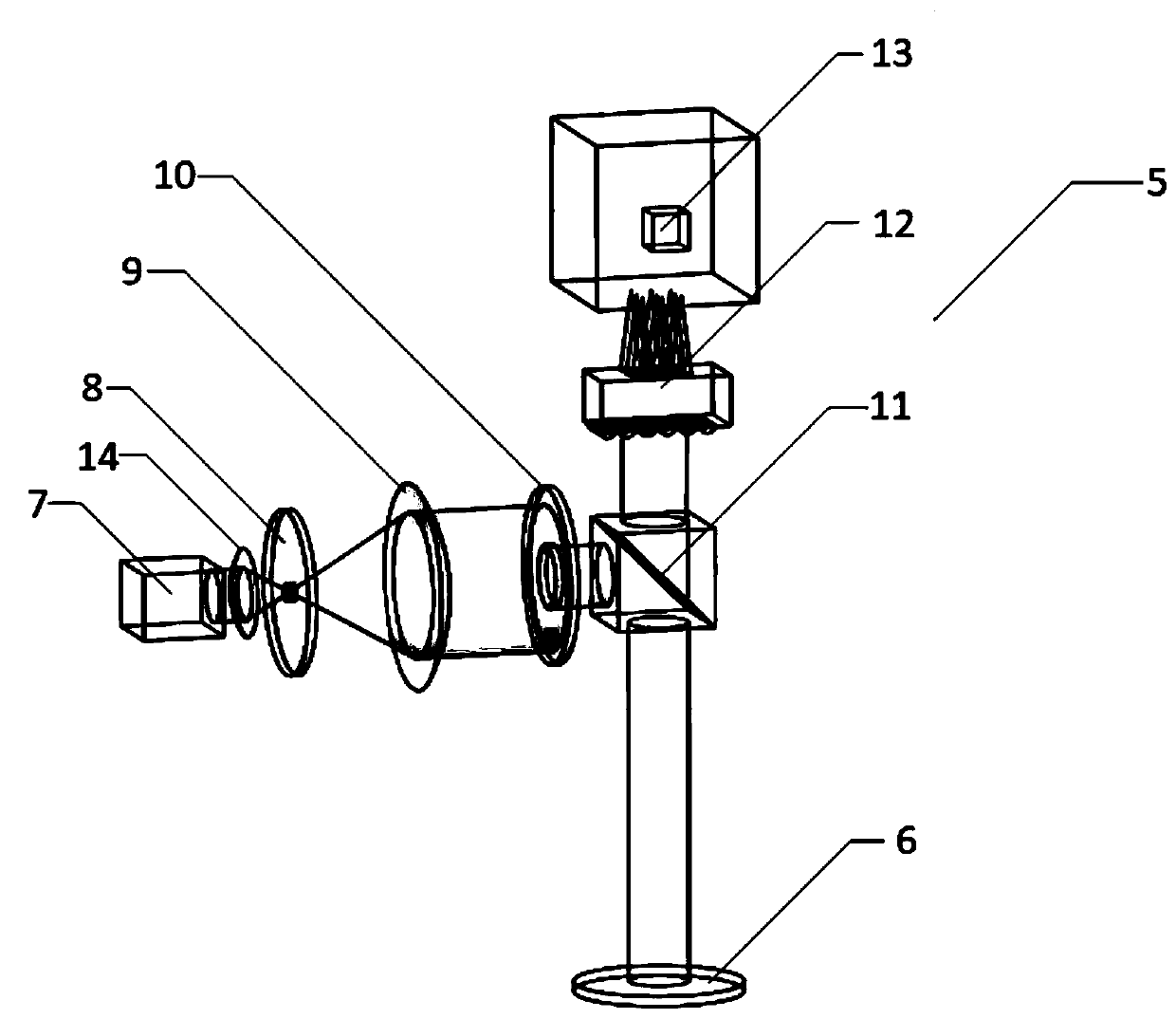

[0072] This embodiment discloses a flatness three-dimensional shape detection device based on complex beam angle adaptive optics, which includes a support 1 , an XY platform 2 , a rotating table 3 , a tilting table 4 , and a complex beam angle sensor 5 . The bracket 1 is used to fix the complex beam angle sensor 5, the XY platform 2 can drive the workpiece 6 to move along the X axis and the Y axis to adjust the measurement radius of the workpiece 6, and the tilt table 4 is used to adjust the inclination of the workpiece 6 angle, the rotary table 3 is used to rotate the workpiece 6, and the complex beam angle sensor 5 includes a semiconductor laser 7, a first filter plate 8, a collimator lens 9, a second filter plate 10, a beam splitter 11, and a microlens array 12, CMOS camera 13.

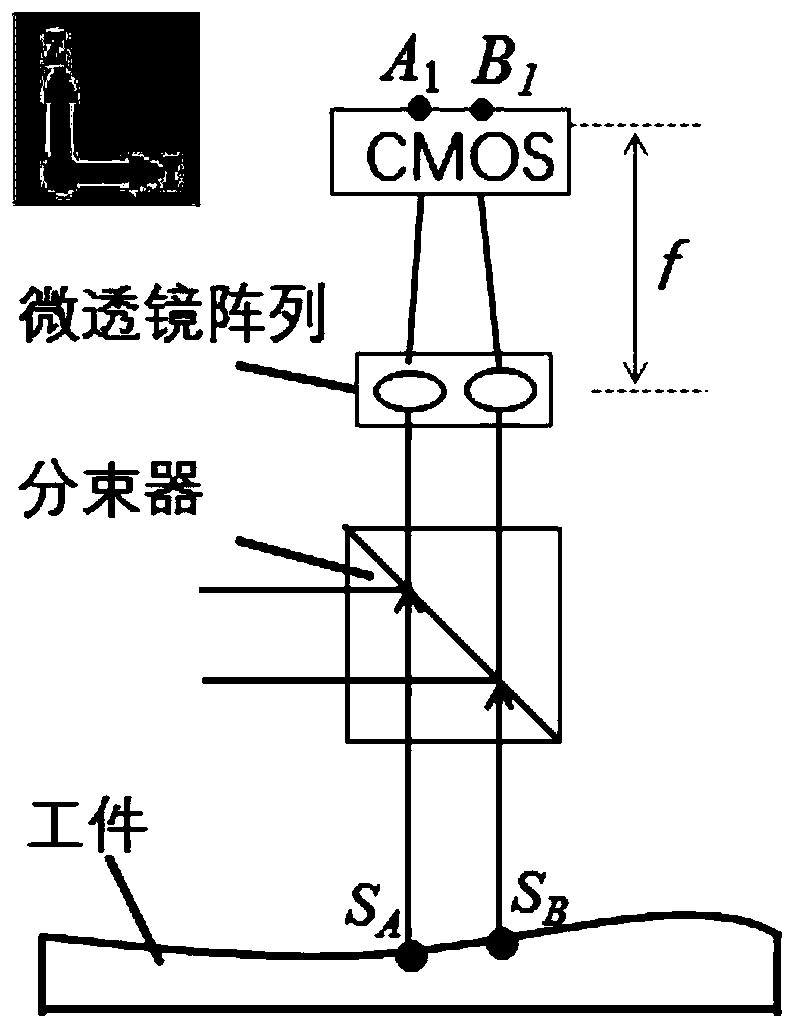

[0073] First introduce the imaging principle of the complex beam angle sensor 5, such as figure 2 As shown, the laser beam from the semiconductor laser 7 passes through the first filter plate 8 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com