Heat preservation bend

A technology of elbows and insulation layers, applied in the field of elbows, can solve problems such as disconnection and insulation elbows that are easy to open, and achieve the effects of high pressure, beautiful appearance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

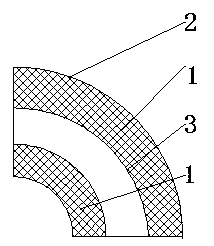

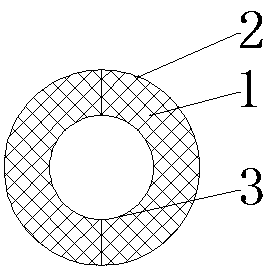

[0017] The invention provides a thermal insulation elbow, which includes two parts that are mirror-symmetrical and airtightly connected, and each part is an outer protective pipe layer 2, an insulating layer 1 and an elbow layer 3 from the outside to the inside in sequence, and the outer protective pipe layer 2 and the elbow layer 3 are pressed into an integrated cavity structure, and the insulation layer 1 is filled in the cavity. The material of the outer protective tube layer 2 and the bent tube layer 3 is metal or polyethylene. The insulation layer 1 is made of polyurethane foam. The bent pipe layer 3 includes bent pipe sections and straight pipe sections extending from the bent pipe sections. The straight pipe section can be directly connected with the heat preservation straight pipe, and the assembly is very convenient. The connection of the two parts is one of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com