Tip screen-out fracturing method

A fracturing and screenout technology, which is applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc. It can solve problems such as short stable production period, rapid decline in pressure and production after fracturing, pressure channeling of adjacent wells, etc. , to achieve the effect of simple construction procedure, convenient on-site operation and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

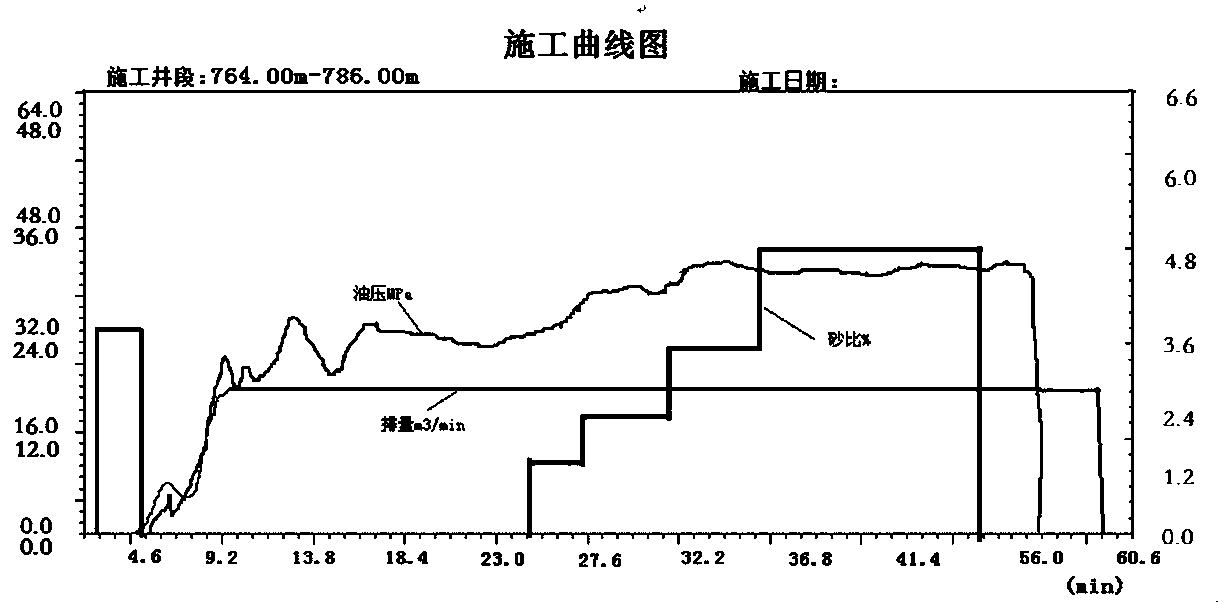

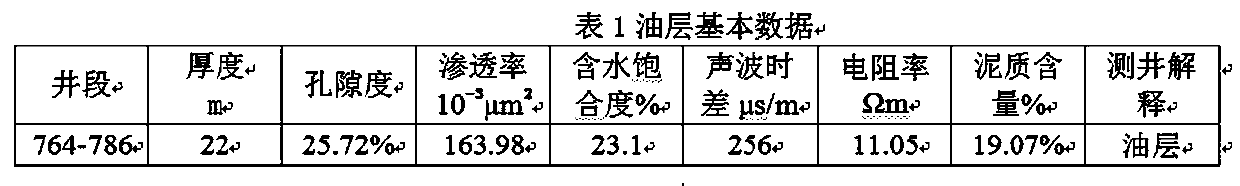

[0027] Embodiment 1, the end screenout fracturing method is carried out according to the following steps: the first step, pumping preflush into the fracturing formation; the second step, the length of the main fracture in the fracturing formation reaches the fracturing design target value In the third step, the high-efficiency filtrate reducer is pumped in; the third step is to pump the high-efficiency filtrate reducer and the sand-carrying fluid is pumped in when the pressure increases; in the fourth step, the replacement fluid is injected, the well is shut down for 2 to 6 hours, and then the well is drained. Test oil and gas production; among them: the volume ratio of pumped pre-fluid, high-efficiency fluid loss fluid and sand-carrying fluid is 10 to 100:4 to 70:30 to 300.

[0028] The end screenout fracturing method of the present invention can be divided into the following four stages, which are respectively the end screenout fracturing design stage, the artificial main fra...

Embodiment 2

[0035] Embodiment 2, the end screenout fracturing method is carried out according to the following steps: the first step is to pump the pre-fluid into the fracturing formation; the second step is to reach the fracturing design target value of the main fracture length of the fracturing formation In the third step, the high-efficiency filtrate reducer is pumped in; the third step is to pump the high-efficiency filtrate reducer and the sand-carrying fluid is pumped in when the pressure increases; the fourth step is to inject the replacement fluid, shut down the well for 2 hours or 6 hours, and then open the well to drain the fluid. Test oil and gas production; where: the volume ratio of pumped pre-fluid, high-efficiency fluid loss fluid and sand-carrying fluid is 10 or 100:4 or 70:30 or 300.

Embodiment 3

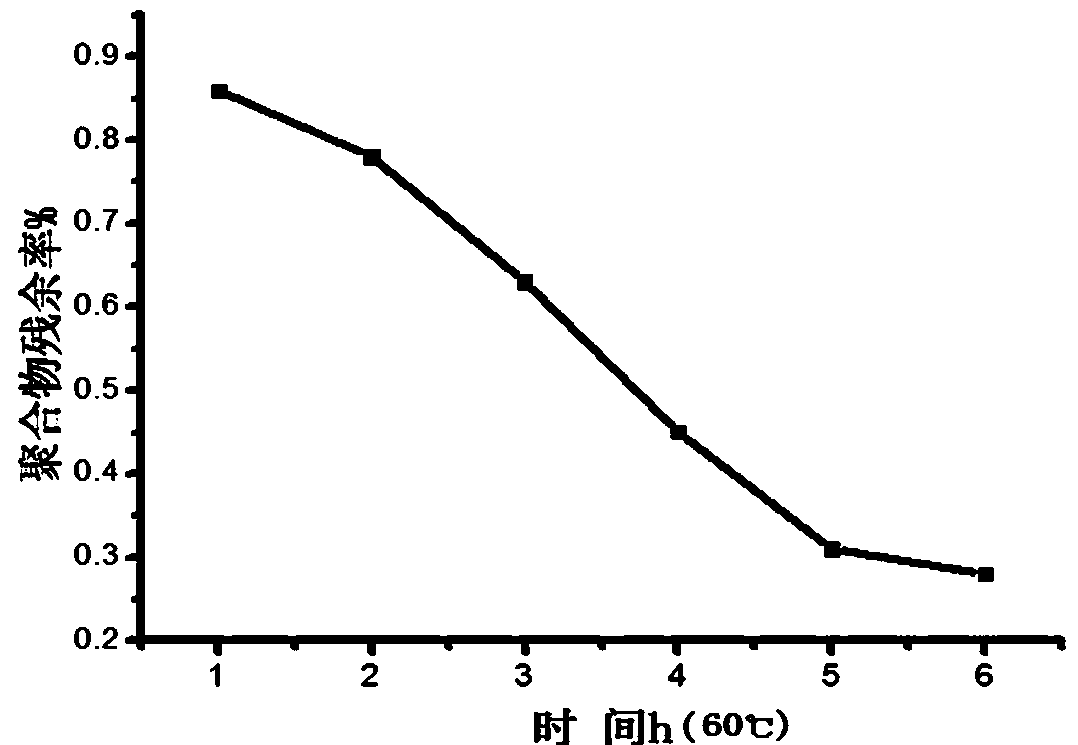

[0036] Embodiment 3, as the optimization of the foregoing embodiments, the high-efficiency fluid loss fluid contains 0.2% to 0.5% of the guar gum base liquid, 1% to 20% of the fluid loss additive, 1% to 10% of the gel breaker, and Discharge agent 0.2% to 2%, clay stabilizer 0.4% to 1%, and the balance is water; or / and, before pumping the high-efficiency fluid loss fluid, adjust the pH of the high-efficiency fluid loss fluid with sodium hydroxide or sodium carbonate Values are 8.5 to 11. The high-efficiency filtrate reducer is an alkaline liquid after the pH value is adjusted, the viscosity is ≤30mPa.s, and the optimum viscosity is 1mPa.s to 10mPa.s; the expansion factor of the fluid loss reducer at 90°C can reach 10 to 60 times, And can maintain good high strength, salt resistance and stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com