Long-life and low-cost steel ladle bottom castable and preparation method thereof

A low-cost, bottom-casting technology, applied in the field of refractory materials, can solve the problems of large waste and fragility of alumina ceramics, and achieve the effect of improving the service life, reducing the thickness of the metamorphic layer, and saving the cost of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

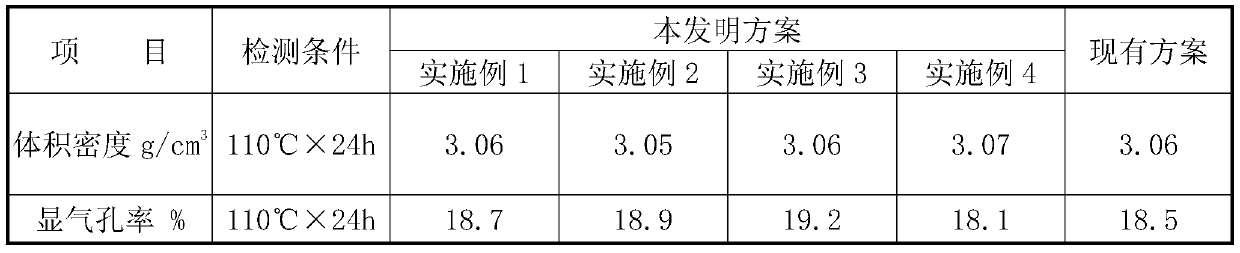

Examples

Embodiment 1

[0027] Step 1, the proportions by weight are: 10-20% of recycled alumina ceramics with a particle size of 15-8mm, 10-15% of recycled alumina ceramics with a particle size of 8-5mm, and recycled alumina ceramics with a particle size of 5-3mm 3-9%, 5-11% of white corundum with a particle size of 5-3mm, 10-20% of white corundum with a particle size of 3-1mm, 1-13% of white corundum with a particle size of 1-0mm, and a particle size of -200 mesh white corundum Corundum 5-13%, particle size of -325 mesh white corundum 1-5%, fused magnesia with particle size of 1-0mm 1-7%, particle size of -200 mesh fused magnesia 1-7%, particle size of 1 -0mm fused aluminum magnesium spinel 1-10%, particle size of -325 mesh pure calcium aluminate cement 1-10%, particle size of 3 microns α-alumina micropowder 2-8%, particle size of 1 micron Alpha-alumina powder 3-8%;

[0028] Step 2, adding recycled alumina ceramics with particle sizes of 15-8mm, 8-5mm, 5-3mm and white corundum with particle sizes ...

Embodiment 2

[0033] Step 1, the proportions by weight are: 10-20% of recycled alumina ceramics with a particle size of 15-8mm, 10-15% of recycled alumina ceramics with a particle size of 8-5mm, and recycled alumina ceramics with a particle size of 5-3mm 3-9%, 5-11% of white corundum with a particle size of 5-3mm, 10-20% of white corundum with a particle size of 3-1mm, 1-13% of white corundum with a particle size of 1-0mm, and a particle size of -200 mesh white corundum Corundum 5-13%, particle size of -325 mesh white corundum 1-5%, fused magnesia with particle size of 1-0mm 1-7%, particle size of -200 mesh fused magnesia 1-7%, particle size of 1 -0mm fused aluminum magnesium spinel 1-10%, particle size of -325 mesh pure calcium aluminate cement 1-10%, particle size of 3 microns α-alumina micropowder 2-8%, particle size of 1 micron Alpha-alumina powder 3-8%;

[0034] Step 2, adding recycled alumina ceramics with particle sizes of 15-8mm, 8-5mm, 5-3mm and white corundum with particle sizes ...

Embodiment 3

[0039] Step 1, according to the proportion by weight: 10-20% of recycled alumina ceramics with a particle size of 15-8mm, 10-15% of recycled alumina ceramics with a particle size of 8-5mm, and recycled alumina ceramics with a particle size of 5-3mm 3-9%, white corundum with a particle size of 5-3mm 5-11%, white corundum with a particle size of 3-1mm 10-20%, white corundum with a particle size of 1-0mm 1-13%, a particle size of -200 mesh white Corundum 5-13%, the particle size is -325 mesh white corundum 1-5%, the particle size is 1-0mm fused magnesia 1-7%, the particle size is -200 mesh fused magnesia 1-7%, the particle size is 1 -0mm fused aluminum magnesium spinel 1-10%, pure calcium aluminate cement with a particle size of -325 mesh 1-10%, α-alumina micropowder with a particle size of 3 microns 2-8%, with a particle size of 1 micron α-alumina micropowder 3-8%;

[0040] Step 2, adding recycled alumina ceramics with particle sizes of 15-8mm, 8-5mm, and 5-3mm and white corund...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com