Coating resin for optical fiber and its preparation method and application

A technology of coating resin and optical fiber coating, applied in the field of optical fiber manufacturing, can solve the problems of difficult discharge of volatile substances, affecting the curing effect of optical fibers, easy accumulation of oil in quartz lamps, etc., so as to ensure the curing effect of optical fibers and improve the photocatalytic curing effect. Efficiency, radiant energy controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

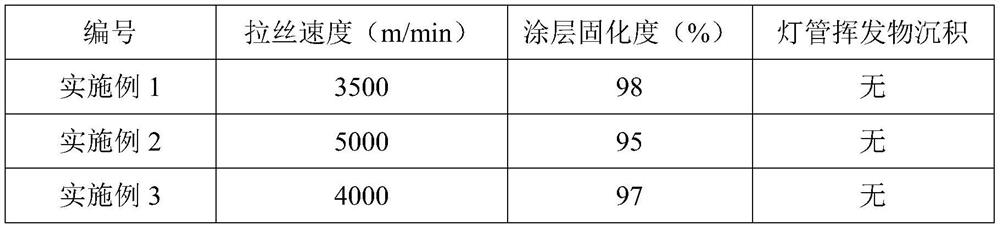

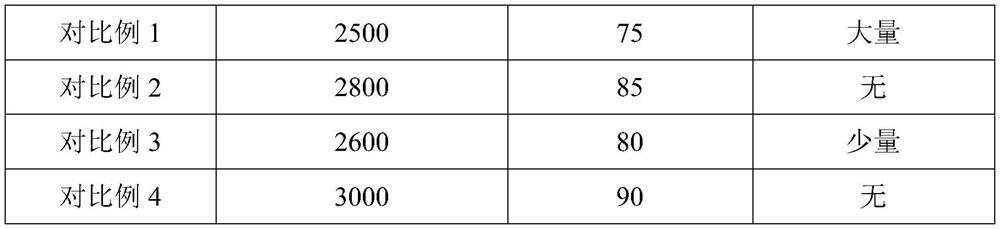

Examples

Embodiment 1

[0038] (1) prepare the first coating resin (the sum of each component is 100wt%):

[0039] (a) 2wt% phenyl (2,4,6-trimethylbenzoyl) phosphine oxide (absorption wavelength 385 ~ 405nm) and 0.005wt% layer number is less than 10 layers, specific surface area 548m 2 The graphene / g is mixed uniformly, and is dissolved in the mixture of 15wt% acrylate-2-phenoxyethyl ester, 1wt% tripropylene glycol diacrylate to obtain photoinitiator-graphene-acrylic monomer premix;

[0040] (b) the photoinitiator-graphene-acrylic monomer premix obtained in step (1) is mixed with 5wt% vinylhexahydro-2H-nitrogen-2-copper, 1wt% 3-trimethoxysilyl Propane-1-mercaptan and the remainder of the polydimethylsiloxane antifoaming agent were uniformly mixed, reacted at 45° C. for 2 hours, and filtered to obtain the first coating resin.

[0041] (2) prepare the second coating resin (the sum of each component is 100wt%):

[0042] (a) 5wt% biphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (absorption wavelength ...

Embodiment 2

[0047] (1) prepare the first coating resin (the sum of each component is 100wt%):

[0048] (a) 6wt% phenyl (2,4,6-trimethylbenzoyl) phosphine oxide (absorption wavelength 385 ~ 405nm) and 0.01wt% layer number is less than 10 layers, specific surface area 608m 2 The graphene of / g mixes homogeneously, dissolves in the mixture of 5wt% acrylate-2-phenoxyethyl ester and 1wt% trimethylolpropane triacrylate, obtains photoinitiator-graphene-acrylic monomer premix thing;

[0049] (b) the photoinitiator-graphene-acrylic monomer premix that step (1) obtains and 1wt% vinyl hexahydro-2H-nitrogen-2-copper, 1wt% 2-ethyl-2- [(3-carboxy-1-oxopropoxy)methyl]propane-1,3-diylbis[3-mercaptopropionic acid] and the rest of the dispersant were mixed evenly, reacted at 60°C for 1 hour, and filtered , to obtain the first coating resin.

[0050] (2) prepare the second coating resin (the sum of each component is 100wt%):

[0051] (a) 1wt% biphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (absorption...

Embodiment 3

[0056] (1) prepare the first coating resin (the sum of each component is 100wt%):

[0057] (a) 3wt% phenyl (2,4,6-trimethylbenzoyl) phosphine oxide (absorption wavelength 385 ~ 405nm) and 0.008wt% layer number is less than 10 layers, specific surface area 658m 2 The graphene / g is mixed evenly, dissolved in the mixture of 10wt% acrylate-2-phenoxyethyl ester, 0.5wt% tripropylene glycol diacrylate and 0.6wt% trimethylolpropane triacrylate to obtain photoinitiated agent-graphene-acrylic monomer premix;

[0058] (b) the photoinitiator-graphene-acrylic monomer premix that step (1) obtains and 4wt% vinyl hexahydro-2H-nitrogen-2-copper, 0.5wt% 3-trimethoxysilane Propane-1-thiol, 0.3 wt% 2-Ethyl-2-[(3-carboxy-1-oxopropoxy)methyl]propane-1,3-diylbis[3-mercaptopropionic acid ] and the remainder of the dispersant were mixed evenly, reacted at 50°C for 1.5h, and filtered to obtain the first coating resin.

[0059] (2) prepare the second coating resin (the sum of each component is 100wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com