Paint spraying line capable of recycling UV ink

A technology for spraying paint lines and inks, which is applied in spray booths, spraying devices, and devices that apply liquid to the surface, etc. It can solve the problems of inconvenient recycling of UV ink and inability to adjust the height of the spray gun.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

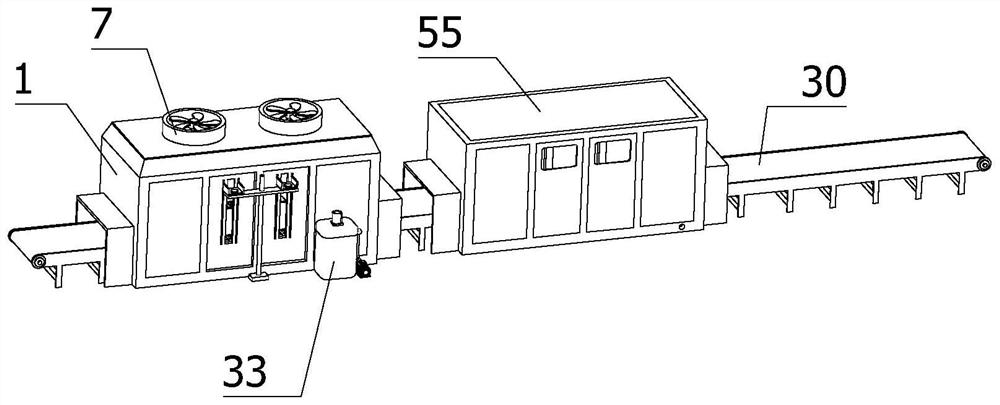

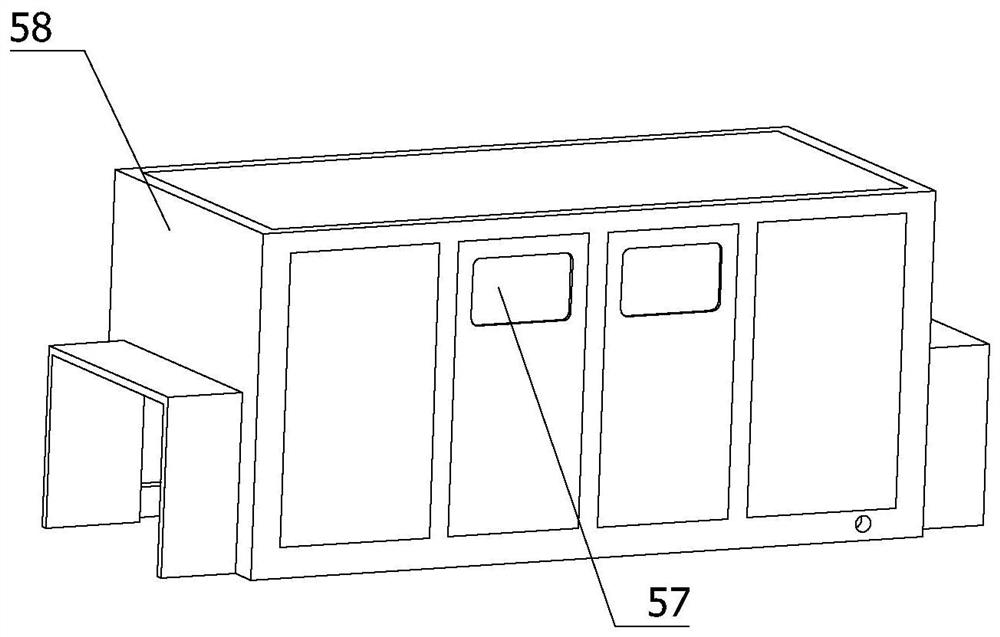

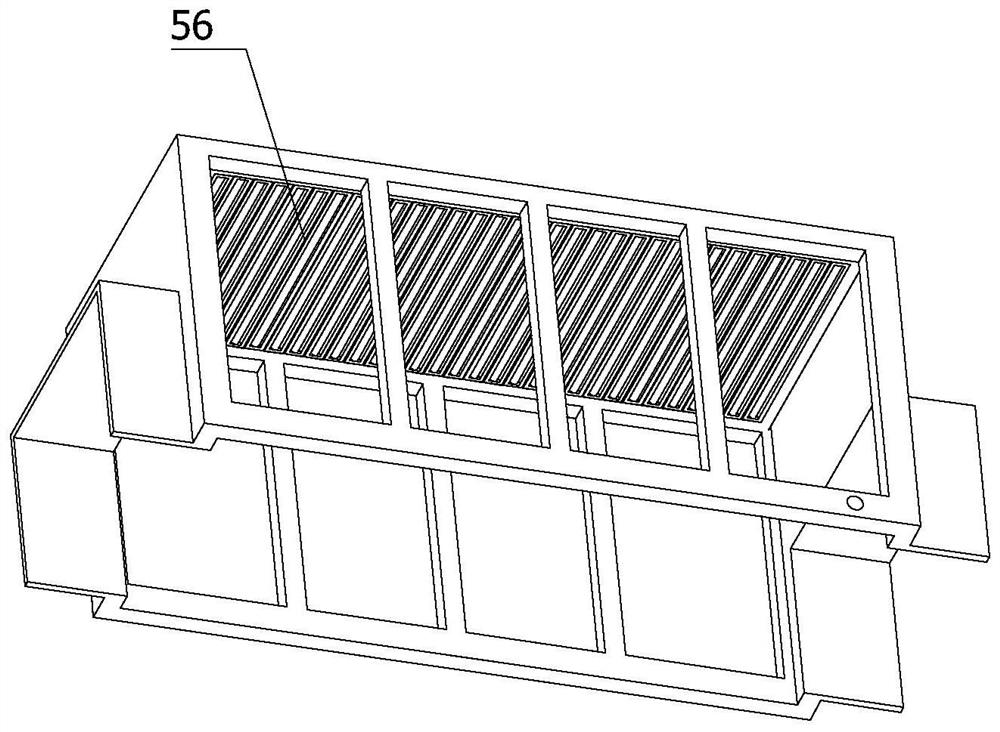

[0036] refer to Figure 1-15 As shown, a painting line that can recycle UV ink, including:

[0037] The spraying mechanism includes a paint spraying box 2, a ventilation fan 7, a paint spraying frame 8, and a spray gun 28. The painting spraying box 2 is spliced by several columns 3 and several mounting plates 4. Fixedly connected, the paint spraying rack 8 is horizontally located between the mounting plates 4 on both sides of the paint spraying box body 2 and is slidably connected with the mounting plate 4, the spray gun 28 is located at the bottom of the paint spraying rack 8, and the paint spraying box 2 is used for airtight inside the box body The space prevents dust from falling on the workpiece duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com