Manufacturing method for trapezoid microflute polishing thin film

A manufacturing method and film technology, applied in the direction of manufacturing tools, grinding/polishing equipment, abrasives, etc., can solve the problems of incoherent production, high production cost, low production efficiency, etc., to avoid cracks, high service life, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

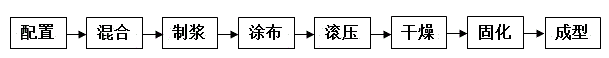

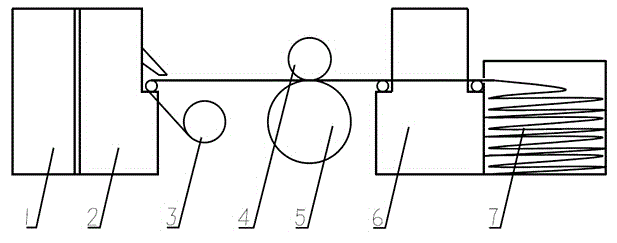

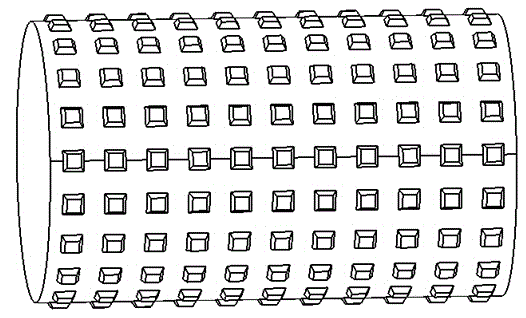

[0026] like figure 1 , figure 2 , image 3 Shown, a kind of manufacture method of trapezoidal microgroove polishing film, comprises the following steps:

[0027] 1) Configuration: configuration of polishing film raw materials without curing agent, wetting agent and defoaming agent;

[0028] 2) Mixing: Input the polished film raw materials that have completed step 1) into the ball mill (1) for mixing;

[0029] 3) Slurry: Input the polished film mixture of step 2) into the mixer (2), add curing agent, wetting agent, and defoamer at the same time, and continuously stir to make slurry;

[0030] 4) Coating: coating the polished film slurry completed in step 3) on the film base layer;

[0031] 5) Rolling: Roll the slurry of the base layer of the film that has completed step 4) through the rolling wheel (4) engraved with a micron-scale protruding positive prism to form a polished film;

[0032] 6) Drying: Send the polished film after step 5) into the drying room (6), and dry it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com