Sludge treatment method for biological treatment of wastewater

A technology of biological treatment and sludge treatment, applied in the direction of biological sludge treatment, sludge treatment, sewage/sludge fertilizer, etc., can solve the problems of poor dehydration, inconvenient storage, difficult compaction, etc., and achieve a more holistic Excellent, easy to store and transport, not prone to debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

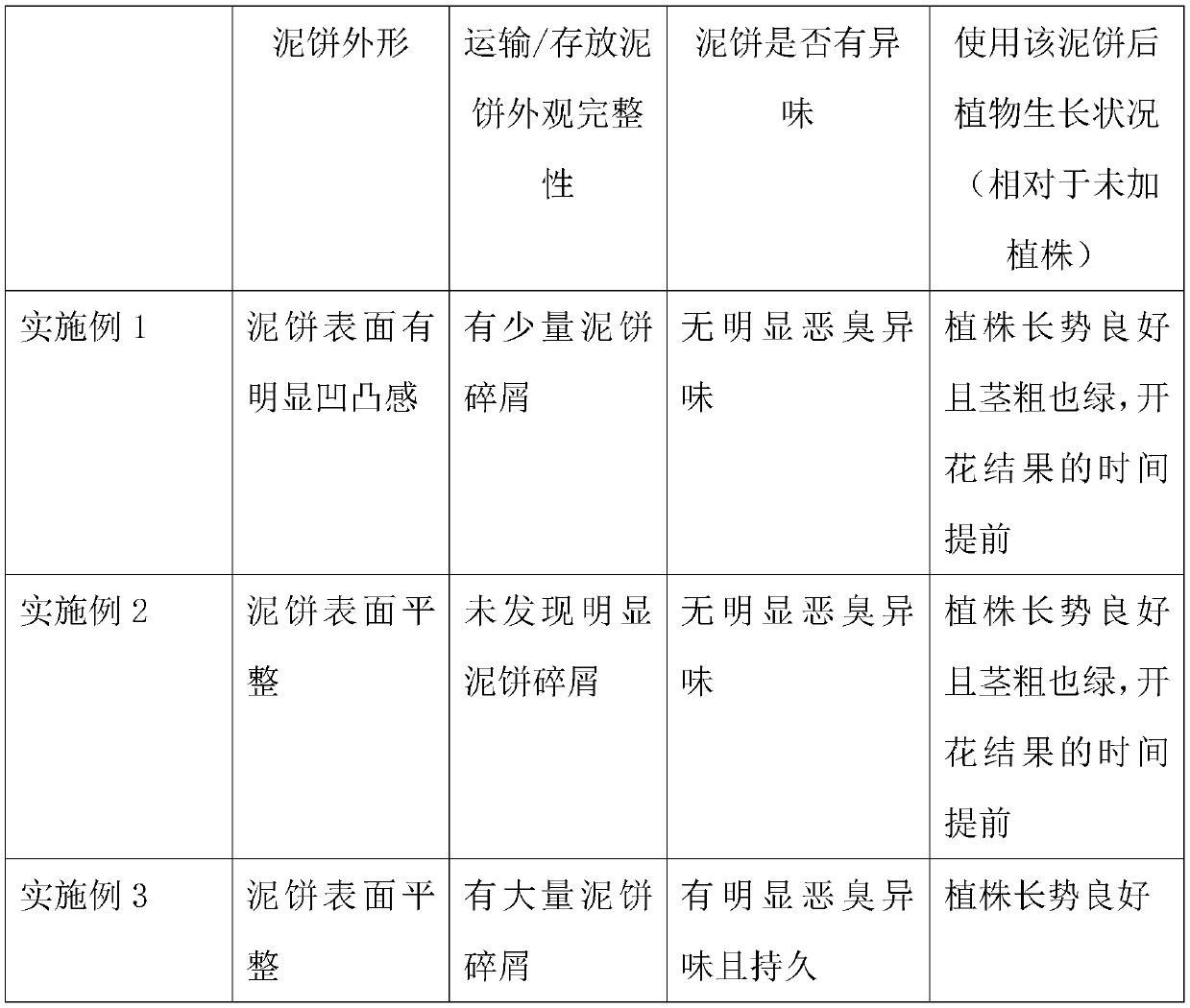

Embodiment 1

[0025] The invention provides a sludge treatment method for wastewater biological treatment, the specific treatment steps are as follows:

[0026] Step 1. Separation of mud and water: the user can first use mechanical excavation to take out part of the sludge, and then use a fine grid to filter the remaining wastewater to separate the remaining sludge from the wastewater. The separated wastewater can be treated separately treatment process;

[0027] Step 2. Fermentation: Put the sludge separated from impurities in step 2 into the digester, and use microbial aerobic / anaerobic fermentation to digest it. The fermentation time is set to 10-15 days, and the sludge The feeding amount is less than 80% of the total volume of the digester. During anaerobic fermentation, the top of the digester should be covered with a cover. The cover is suitable for the inner cavity of the digester, and the cover is set as a steel floating cover. It can rise and fall with the liquid level in the pool...

Embodiment 2

[0033] The invention provides a sludge treatment method for wastewater biological treatment, the specific treatment steps are as follows:

[0034] Step 1. Separation of mud and water: the user can first use mechanical excavation to take out part of the sludge, and then use a fine grid to filter the remaining wastewater to separate the remaining sludge from the wastewater. The separated wastewater can be treated separately treatment process;

[0035] Step 2. Separation of sand and gravel: put the sludge separated in step 1 on the vibrating screen machine for screening, and the fluid sludge will be left along the sieve holes of the vibrating screen machine, while the large-diameter sundries or gravel The sieve remains on the top of the vibrating screen machine, and the user can use the waste water in step 1 to wash the separated sundries and gravel, and then use part of the clean water to wash, and the rinsing water and sewage are collected for centralized treatment. Can be rec...

Embodiment 3

[0042] The invention provides a sludge treatment method for wastewater biological treatment, the specific treatment steps are as follows:

[0043] Step 1. Separation of mud and water: the user can first use mechanical excavation to take out part of the sludge, and then use a fine grid to filter the remaining wastewater to separate the remaining sludge from the wastewater. The separated wastewater can be treated separately treatment process;

[0044] Step 2. Separation of sand and gravel: put the sludge separated in step 1 on the vibrating screen machine for screening, and the fluid sludge will be left along the sieve holes of the vibrating screen machine, while the large-diameter sundries or gravel The sieve remains on the top of the vibrating screen machine, and the user can use the waste water in step 1 to wash the separated sundries and gravel, and then use part of the clean water to wash, and the rinsing water and sewage are collected for centralized treatment. Can be rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com